Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Drilling Fluids Specialist interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Drilling Fluids Specialist so you can tailor your answers to impress potential employers.

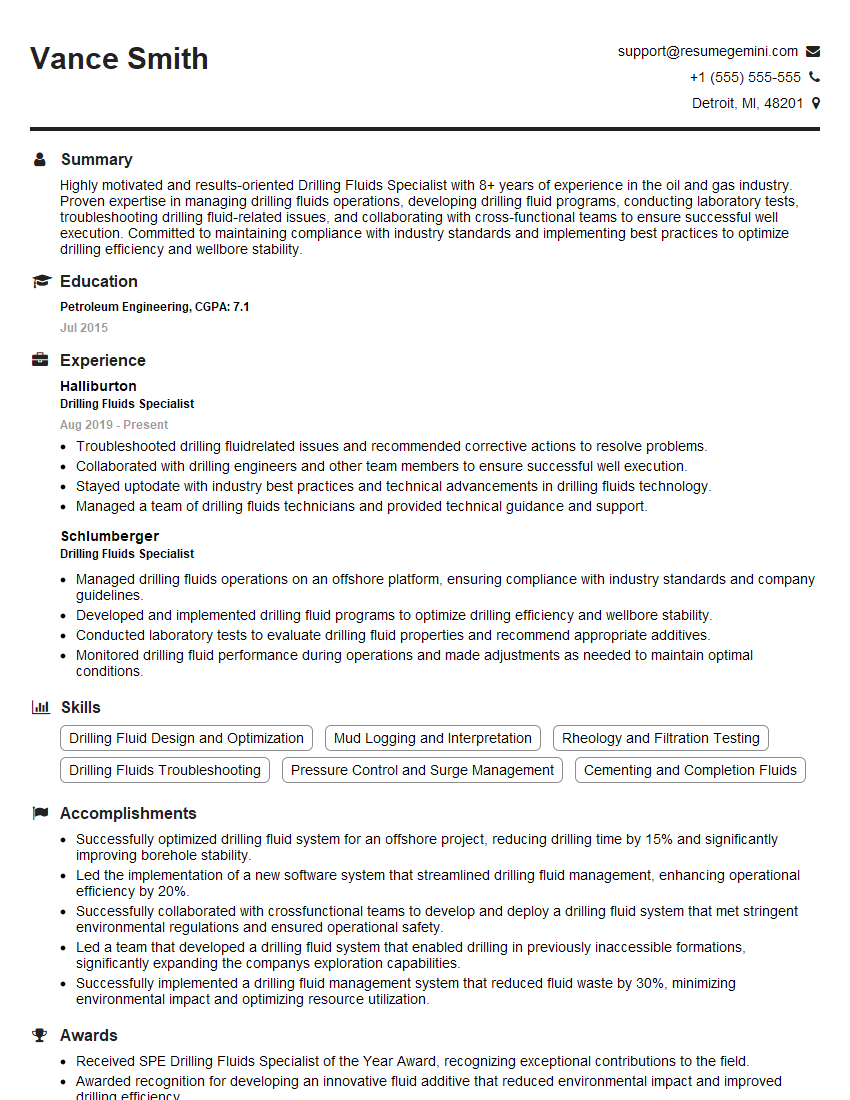

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drilling Fluids Specialist

1. How do you determine the correct mud weight to maintain wellbore stability?

The correct mud weight is determined by several factors, including:

- Pore pressure of the formations being drilled

- Fracture gradient

- Depth of the wellbore

- Drilling fluid properties

- Type of drilling operation being performed

2. What are the key properties of drilling fluids and how do you measure them?

Density:

Measured with a mud balanceViscosity:

Measured with a viscometerYield point:

Measured with a yield point testerGel strength:

Measured with a gel strength testerpH:

Measured with a pH meterSolids content:

Measured with a solids content analyzer

3. How do you control the viscosity of drilling fluids?

Viscosity can be controlled by adding various chemicals, such as:

- Bentonite

- Polymers

- Xanthan gum

- Diesel

4. How do you prevent lost circulation?

Lost circulation can be prevented by:

- Maintaining proper mud weight

- Using lost circulation materials (LCMs)

- Reducing drilling rate

- Setting casing

5. How do you troubleshoot drilling fluid problems?

Drilling fluid problems can be troubleshooted by:

- Identifying the problem

- Determining the cause of the problem

- Developing a solution to the problem

- Implementing the solution

- Monitoring the effectiveness of the solution

6. What are the safety concerns associated with drilling fluids?

- Exposure to hazardous chemicals

- Fire

- Explosion

- Slips, trips, and falls

7. How do you develop a drilling fluid program?

A drilling fluid program is developed by:

- Determining the objectives of the drilling operation

- Selecting the appropriate drilling fluid system

- Designing the drilling fluid properties

- Establishing drilling fluid maintenance procedures

- Monitoring the drilling fluid performance

8. What are the different types of drilling fluids?

- Water-based muds

- Oil-based muds

- Synthetic-based muds

- Pneumatic drilling fluids

9. How do you handle and dispose of drilling fluids?

Drilling fluids are handled and disposed of in accordance with local regulations.

10. What is the role of the Drilling Fluids Specialist?

The Drilling Fluids Specialist is responsible for:

- Developing and implementing drilling fluid programs

- Monitoring drilling fluid performance

- Troubleshooting drilling fluid problems

- Training drilling personnel on drilling fluid issues

- Working with other members of the drilling team to ensure safe and efficient drilling operations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drilling Fluids Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drilling Fluids Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Intro paragraph: A Drilling Fluids Specialist is responsible for designing, implementing, and monitoring drilling fluids programs to ensure optimal drilling performance. Key responsibilities include:

1. Drilling Fluids Management

Intro paragraph: Plan, design, and optimize drilling fluid systems to meet specific wellbore conditions.

- Select and recommend appropriate drilling fluids based on wellbore geology, drilling parameters, and environmental regulations.

- Monitor and adjust drilling fluid properties (e.g., density, viscosity, filtration) to maintain wellbore stability and prevent formation damage.

2. Solids Control and Waste Management

Intro paragraph: Implement and manage solids control systems to remove cuttings and contaminants from drilling fluids.

- Design and operate solids control equipment (e.g., shakers, centrifuges, desanders) to effectively separate solids.

- Develop and implement waste management plans to dispose of drilling fluids and cuttings in an environmentally responsible manner.

3. Laboratory Testing and Analysis

Intro paragraph: Conduct laboratory tests to evaluate drilling fluid properties and diagnose wellbore problems.

- Perform tests such as rheology, fluid loss, and solids analysis to determine drilling fluid performance.

- Interpret test results and provide recommendations to optimize drilling fluid formulations.

4. Troubleshooting and Problem Solving

Intro paragraph: Identify and resolve drilling fluid-related problems to minimize downtime and ensure drilling efficiency.

- Diagnose and troubleshoot drilling fluid issues (e.g., lost circulation, stuck pipe, wellbore instability).

- Develop and implement corrective actions to address drilling fluid problems and improve drilling performance.

Interview Tips

Intro paragraph: To ace your interview for a Drilling Fluids Specialist position, consider the following tips:

1. Research Industry Trends and Innovations

Intro paragraph: Demonstrate your knowledge of the latest drilling fluids technologies and industry best practices.

- Read industry publications, attend conferences, and follow leading experts in the field.

- Be prepared to discuss your understanding of emerging trends and how they could impact drilling operations.

2. Highlight Your Practical Experience

Intro paragraph: Emphasize your hands-on experience in drilling fluids management and problem-solving.

- Describe specific examples of how you have successfully optimized drilling fluid systems to improve drilling performance.

- Provide quantifiable results that demonstrate your ability to reduce downtime and enhance efficiency.

3. Showcase Your Problem-Solving Skills

Intro paragraph: Demonstrate your analytical thinking and ability to troubleshoot drilling fluid-related issues.

- Prepare examples of how you have successfully diagnosed and resolved drilling fluid problems in challenging wellbore conditions.

- Discuss your approach to problem-solving and how you develop and implement effective solutions.

4. Emphasize Teamwork and Communication

Intro paragraph: Highlight your ability to work effectively with drilling teams and communicate technical information clearly.

- Describe your experience collaborating with engineers, drillers, and other stakeholders to optimize drilling fluid programs.

- Provide examples of how you have effectively presented technical concepts and recommendations to management and clients.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drilling Fluids Specialist interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.