Feeling lost in a sea of interview questions? Landed that dream interview for Drilling Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Drilling Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

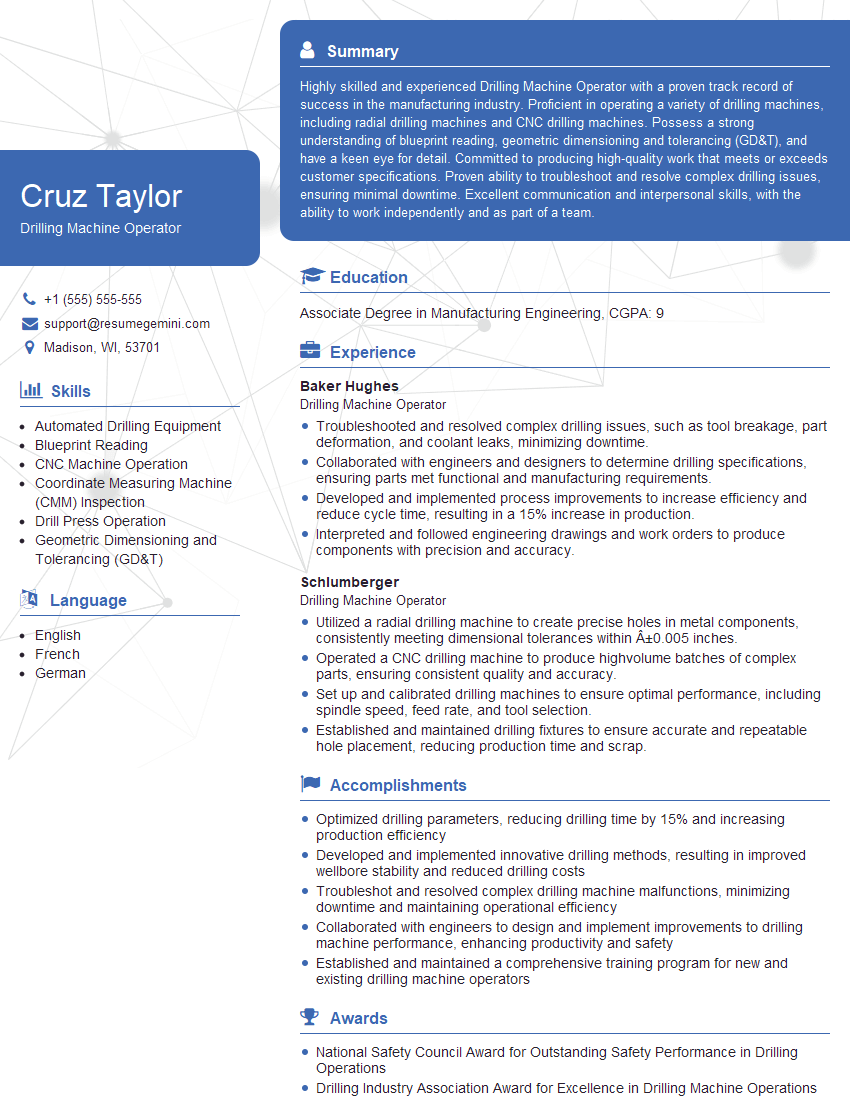

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drilling Machine Operator

1. Explain the different types of drilling machines and their applications?

There are various types of drilling machines designed for specific applications. Some common types include:

- Radial drilling machine: Used for drilling large holes in heavy workpieces, with the drill head mounted on a radial arm that allows for precise positioning.

- Upright drilling machine: Suitable for smaller workpieces and precision drilling operations, with the drill spindle mounted vertically in a column.

- Horizontal drilling machine: Used for drilling horizontal holes in large workpieces, such as beams or pipes, where the workpiece is mounted on a table and the drill spindle is stationary.

- Gang drilling machine: Consists of multiple drill spindles mounted on a common base, allowing for simultaneous drilling of multiple holes in a workpiece.

- CNC drilling machine: Computer-controlled machines that offer precise drilling and automation, often used in mass production environments.

2. Describe the safety precautions you take while operating a drilling machine?

Safe Work Environment

- Ensure the work area is well-lit and free of clutter.

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection.

Machine Operation

- Inspect the machine before use to ensure it is in good working condition.

- Securely anchor the workpiece in the machine’s vise or fixture.

- Set the correct drill speed and feed rate based on the material being drilled.

- Avoid excessive force when drilling, as this can cause the drill bit to break.

Emergency Preparedness

- Be aware of the machine’s emergency stop button and know how to use it.

- Have a plan for dealing with potential hazards, such as broken drill bits or electrical malfunctions.

3. How do you determine the correct drill bit size and type for a given application?

- Material: Consider the hardness and thickness of the material being drilled.

- Hole size: Determine the desired diameter and depth of the hole.

- Accuracy: Select a drill bit that provides the required precision for the application.

- Drill bit type: Choose the appropriate drill bit type based on the material, such as high-speed steel (HSS) for general-purpose drilling or carbide-tipped bits for harder materials.

- Drill bit diameter: Use a drill bit that is slightly smaller than the desired hole size to allow for clearance.

4. Explain the importance of lubrication when drilling?

- Reduces friction: Lubrication minimizes friction between the drill bit and the workpiece, preventing overheating and premature wear.

- Improves cutting efficiency: With reduced friction, the drill bit cuts more smoothly, resulting in better surface finish and longer tool life.

- Cools the workpiece and drill bit: The lubrication acts as a coolant, preventing the workpiece and drill bit from overheating due to friction.

- Prevents chip welding: Lubrication helps break and remove chips from the cutting zone, reducing the risk of chip welding (sticking) to the drill bit.

5. What is the purpose of a coolant in drilling operations?

- Cooling: The coolant reduces the temperature of the drill bit and workpiece, preventing thermal damage and extending tool life.

- Lubrication: Coolant acts as a lubricant, minimizing friction and improving cutting efficiency.

- Chip removal: The coolant helps flush away metal chips from the cutting zone, preventing chip welding and ensuring a clean cut.

- Corrosion prevention: Some coolants contain additives that protect the workpiece and drill bit from corrosion.

6. How do you ensure the accuracy of drilled holes?

- Proper drill bit selection: Use a drill bit that is sharp and of the correct size and type for the material being drilled.

- Precise machine setup: Ensure that the drilling machine is properly aligned and calibrated.

- Secure workpiece: Firmly clamp or fixture the workpiece to prevent movement during drilling.

- Use drill guides or templates: For precise hole placement, utilize drill guides or templates to guide the drill bit.

- Measure and mark the workpiece: Accurately mark the desired hole locations before drilling to guide the process.

7. Explain the factors that affect the drilling rate?

- Drill bit material and geometry: The type of drill bit material (e.g., HSS, carbide) and its geometry (e.g., helix angle, flute shape) influence cutting efficiency.

- Workpiece material: The hardness, thickness, and composition of the workpiece affect the required cutting force and drilling rate.

- Drill speed and feed rate: The optimal speed and feed rate combination for a given material and drill bit size must be determined to achieve maximum efficiency.

- Machine condition: The condition of the drilling machine, including its spindle rigidity, spindle speed range, and overall accuracy, can affect the drilling rate.

- Lubrication: Proper lubrication reduces friction and improves cutting efficiency, resulting in a higher drilling rate.

8. How do you maintain the drilling machine to ensure optimal performance?

- Regular cleaning: Keep the machine clean and free of debris to prevent damage or malfunctions.

- Lubrication: Follow the manufacturer’s guidelines for lubrication, including greasing moving parts and oiling gears.

- Drill bit inspection: Regularly inspect drill bits for wear or damage, and replace them as needed.

- Spindle maintenance: Ensure the spindle is clean, well-lubricated, and running smoothly without excessive noise or vibration.

- Table alignment: Periodically check and adjust the table alignment to maintain precision.

9. What types of cutting fluids are commonly used in drilling operations?

- Water-based fluids: These are non-flammable and provide cooling and lubrication.

- Oil-based fluids: Offer excellent lubrication and protection against wear, but can be more difficult to clean and may pose environmental concerns.

- Synthetic fluids: Provide a balance of cooling, lubrication, and environmental friendliness.

- Solid lubricants: Can be applied dry or in a paste form to reduce friction and improve tool life.

10. Describe the process of sharpening a drill bit?

- Inspect the drill bit: Check for damage or wear, and determine the required sharpening angle.

- Select a grinding wheel: Choose a grinding wheel with the appropriate grit and shape for the drill bit material.

- Secure the drill bit: Clamp the drill bit in a grinding vise or fixture to ensure stability.

- Grind the cutting edges: Hold the drill bit against the grinding wheel and grind the cutting edges to the desired angle.

- Thin the web: If necessary, thin the web (the area between the cutting edges) to reduce friction and improve chip clearance.

- Inspect and test: Inspect the sharpened drill bit for burrs or imperfections, and test its sharpness by drilling a hole in a scrap material.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drilling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drilling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drilling Machine Operators are responsible for operating and maintaining drilling machines, which are used to create holes in various materials for assembly, production, and other purposes.

1. Operating Drilling Machines

The primary duty of a Drilling Machine Operator is to use the drilling machine to create holes in workpieces. This involves setting up the machine, selecting the appropriate drill bit, and adjusting the machine’s settings for the desired depth, speed, and feed rate.

- Select and install the correct drill bit for the material and hole size.

- Secure the workpiece in place on the machine table.

- Set the drilling depth, speed, and feed rate.

- Initiate the drilling process and monitor its progress.

- Make adjustments to the machine settings as needed to ensure accurate and efficient drilling.

2. Maintenance and Troubleshooting

Drilling Machine Operators are also responsible for maintaining and troubleshooting the drilling machine. This involves regular cleaning, lubrication, and inspection of the machine, as well as identifying and resolving any issues that arise during operation.

- Clean and lubricate the machine according to manufacturer’s instructions.

- Inspect the machine for damage or wear and tear.

- Troubleshoot and resolve common machine problems, such as drill bit breakage or misalignment.

- Report any major issues to a supervisor or maintenance technician.

3. Quality Control

Drilling Machine Operators are responsible for ensuring the quality of the holes they produce. This involves visually inspecting the holes for accuracy, cleanliness, and surface finish, and using measuring tools to verify that the holes meet the required specifications.

- Visually inspect the holes for accuracy, cleanliness, and surface finish.

- Use measuring tools to verify that the holes meet the required specifications.

- Reject or rework workpieces with unacceptable holes.

4. Safety and Compliance

Drilling Machine Operators are responsible for following all safety protocols and regulations related to the operation of drilling machines. This includes wearing appropriate personal protective equipment (PPE), such as safety glasses, earplugs, and gloves, and following proper lockout/tagout procedures when performing maintenance or repairs.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures when performing maintenance or repairs.

- Report any safety hazards or concerns to a supervisor.

Interview Tips

Preparing thoroughly for an interview can help you present yourself confidently and increase your chances of landing the job. Here are some tips to help you ace your interview for a Drilling Machine Operator position:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Drilling Machine Operator position you are applying for. This will show the interviewer that you are interested in the company and the role, and that you have put in the effort to learn about the organization and its needs.

- Visit the company’s website to learn about its history, mission, products or services, and company culture.

- Read the job description carefully and identify the key requirements and responsibilities.

2. Practice Your Answers

Once you have researched the company and the position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Prepare answers to questions about your experience operating drilling machines, your knowledge of drilling techniques, and your ability to troubleshoot and resolve problems.

- Practice answering questions about your safety awareness and compliance with regulations.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Drilling Machine Operator position. Use specific examples to demonstrate your abilities and how they have benefited previous employers.

- Emphasize your experience in operating drilling machines and your ability to produce high-quality holes.

- Discuss your knowledge of different drilling techniques and materials.

- Share examples of how you have successfully maintained and troubleshooted drilling machines.

4. Be Enthusiastic and Professional

First impressions matter, so be sure to dress professionally and arrive on time for your interview. Throughout the interview, maintain a positive and enthusiastic attitude, and be respectful of the interviewer’s time and questions.

- Dress in clean, professional attire.

- Arrive on time for your interview.

- Make eye contact with the interviewer and speak clearly and confidently.

5. Ask Questions

At the end of the interview, take the opportunity to ask the interviewer questions about the company, the position, and the next steps in the hiring process. This shows that you are engaged and interested in the opportunity.

- Ask about the company’s growth plans and future prospects.

- Inquire about the training and development opportunities available for Drilling Machine Operators.

- Ask about the company’s safety record and its commitment to employee safety.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Drilling Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.