Are you gearing up for an interview for a Drip Molder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Drip Molder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

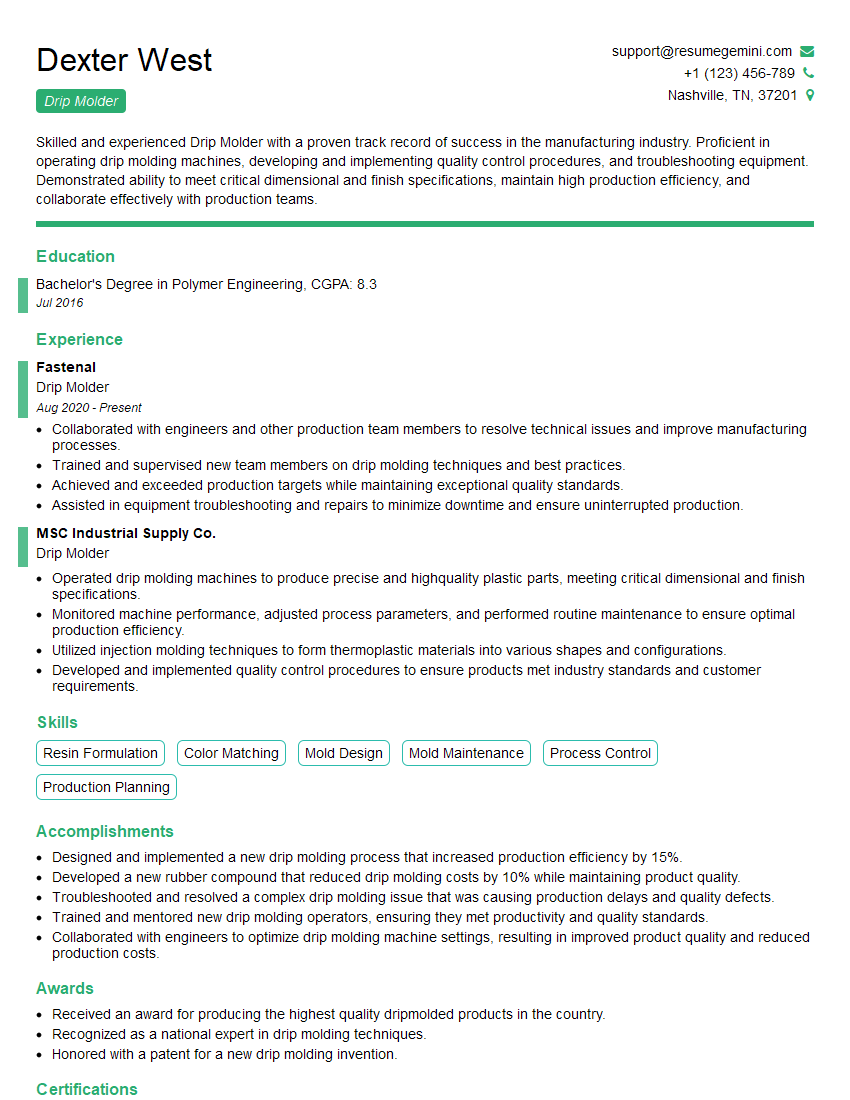

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drip Molder

1. What are the key process parameters involved in drip molding and how do they affect the quality of the molded part?

- Drip Rate: Determines the thickness and shape of the part. Higher drip rate leads to thicker parts with less detail.

- Mold Temperature: Affects the cooling rate and crystallinity of the polymer. Higher mold temperature results in slower cooling and higher crystallinity.

- Mold Material: Influences the surface finish and texture of the part. Different mold materials have different thermal and release properties.

- Polymer Viscosity: Impacts the flowability and mold filling. Higher viscosity requires higher injection pressure and can lead to part defects.

- Mold Design: Determines the shape, size, and features of the molded part. Optimal mold design ensures proper polymer flow and ejection.

2. Describe the different types of polymers commonly used in drip molding and their applications.

Thermoplastics

- Polyethylene (PE): High-density (HDPE) for pipes, bottles; low-density (LDPE) for bags, films.

- Polypropylene (PP): Containers, automotive parts, medical devices.

- Polystyrene (PS): Disposable cups, plates, toys.

Thermosets

- Epoxy: Adhesives, electrical components.

- Polyurethane: Foams, elastomers, coatings.

- Silicone: Seals, gaskets, medical implants.

3. Explain how you would troubleshoot common defects in drip molded parts, such as voids, sinks, and flash?

- Voids: Optimize drip rate, adjust mold temperature, modify polymer viscosity, check for mold leaks.

- Sinks: Increase mold temperature, adjust drip rate, modify polymer viscosity, improve mold design for uniform cooling.

- Flash: Improve mold alignment, adjust injection pressure, redesign mold for better sealing, optimize polymer viscosity.

4. What quality control measures are important in drip molding to ensure consistent product quality?

- Process Parameter Monitoring: Monitor drip rate, mold temperature, injection pressure, and other process variables.

- Dimensional Inspection: Measure critical dimensions of molded parts using CMMs, calipers, or other measuring tools.

- Visual Inspection: Check for defects such as voids, sinks, flash, and surface imperfections.

- Material Testing: Perform tensile, flexural, and other mechanical tests to verify material properties.

- Statistical Process Control (SPC): Collect and analyze data to identify trends and improve process stability.

5. Describe the safety precautions that should be taken when operating drip molding equipment.

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Ensure proper ventilation to remove hazardous fumes and vapors.

- Follow lockout/tagout procedures when servicing or adjusting equipment.

- Handle hot molds with caution and use proper lifting techniques.

- Be aware of potential electrical hazards and keep equipment well-grounded.

6. What are the advantages and disadvantages of drip molding compared to other molding processes like injection molding or compression molding?

Advantages

- Low-cost tooling and equipment.

- Suitable for small batch production.

- Capable of producing complex shapes with intricate details.

- Versatile for various materials, including thermoplastics and thermosets.

Disadvantages

- Relatively slow process.

- Manual labor-intensive.

- Not suitable for high-volume production.

7. How do you stay up-to-date with the latest advances and best practices in drip molding technology?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and LinkedIn groups.

- Network with other drip molders and industry experts.

8. What is your experience with designing and optimizing mold systems for drip molding?

Discuss experience in mold design software, flow simulation, and mold optimization techniques to improve part quality and efficiency.

9. How do you handle quality control and ensure the production of high-quality drip molded parts?

Describe quality control processes, inspection techniques, and corrective actions taken to identify and resolve quality issues.

10. Can you provide examples of successful projects or innovations where you applied drip molding technology?

Showcase projects where drip molding was used effectively to solve specific manufacturing challenges and deliver successful outcomes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drip Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drip Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Drip Molder is responsible for the operation and maintenance of drip molding machines. They ensure that the machines are running smoothly and efficiently, and that the products being produced meet quality standards.

1. Machine Operation

- Starts, stops, and monitors drip molding machines

- Loads raw materials into the machines and operates the controls to produce products

- Inspects finished products for defects and ensures they meet specifications

2. Machine Maintenance

- Performs routine maintenance on drip molding machines, including cleaning and lubrication

- Troubleshoots and repairs minor malfunctions

- Reports major malfunctions to supervisors for repair

3. Quality Control

- Monitors product quality and makes adjustments to the molding process as needed

- Inspects finished products for defects and ensures they meet specifications

- Maintains records of product quality and machine performance

4. Safety

- Follows all safety regulations and procedures

- Wears appropriate safety gear, including gloves, safety glasses, and earplugs

- Maintains a clean and organized work area

Interview Tips

The following are some tips to help you prepare for an interview for a Drip Molder position.

1. Research the company and the position

- Visit the company’s website to learn about their products, services, and culture

- Read the job description carefully and identify the key requirements for the position

- Prepare questions to ask the interviewer about the company and the position

2. Highlight your experience and skills

- Quantify your experience and skills whenever possible

- Use specific examples to demonstrate your abilities

- Tailor your resume and cover letter to the specific requirements of the position

3. Be prepared to talk about your safety experience

- Describe your experience with following safety regulations and procedures

- Explain how you maintain a clean and organized work area

- Highlight any safety training or certifications you have

4. Be confident and enthusiastic

- Smile and make eye contact with the interviewer

- Speak clearly and confidently

- Show your enthusiasm for the position and the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drip Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!