Are you gearing up for a career in Drop Hammer Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Drop Hammer Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

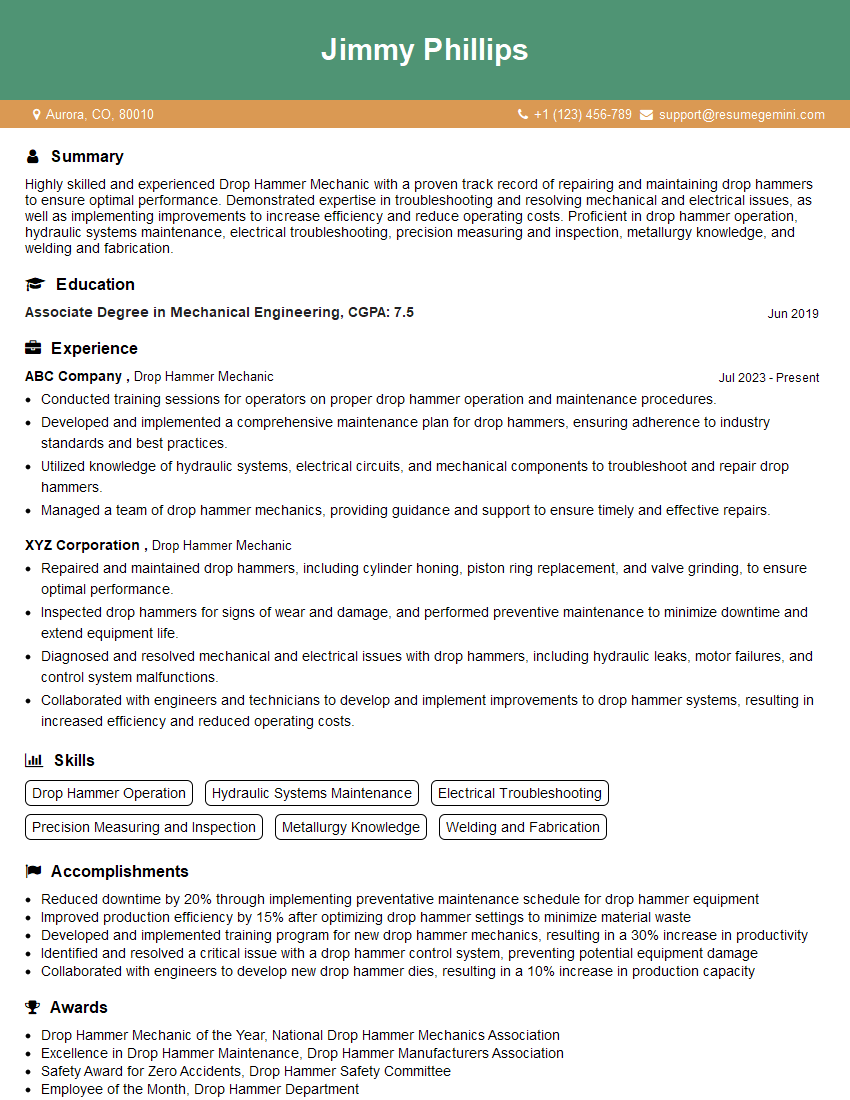

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drop Hammer Mechanic

1. Describe the process of setting up a drop hammer for forging operations?

- Inspect the hammer and its components for any damage or wear.

- Select the appropriate dies and install them securely into the hammer.

- Adjust the hammer’s stroke length and impact force to suit the forging requirements.

- Lubricate the moving parts of the hammer to minimize friction and wear.

- Calibrate the hammer’s controls to ensure accurate and repeatable operation.

2. How do you maintain the accuracy of a drop hammer?

Calibration and Inspection

- Regularly calibrate the hammer’s controls to ensure it is striking with the correct force and precision.

- Inspect the dies and other components for wear or damage, and replace or repair them as needed.

Alignment and Lubrication

- Check the alignment of the hammer and dies to maintain accuracy and prevent misalignment.

- Lubricate the moving parts regularly to minimize friction and ensure smooth operation.

3. What are the safety precautions that must be followed when operating a drop hammer?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Ensure the work area is clear of obstructions and potential hazards.

- Check the hammer and its components before each use to ensure they are in good working order.

- Never operate the hammer under the influence of drugs or alcohol.

- Follow established safety protocols and procedures at all times.

4. How do you troubleshoot common problems with drop hammers?

- Identify the symptoms of the problem, such as reduced impact force, inaccurate strikes, or excessive vibration.

- Inspect the hammer and its components for any visible damage or wear.

- Check the calibration of the hammer’s controls and adjust them if necessary.

- Lubricate the moving parts of the hammer to reduce friction and ensure smooth operation.

- If the problem persists, consult the manufacturer’s instructions or seek professional assistance.

5. What are the different types of forging operations that can be performed using a drop hammer?

- Open-die forging: Shaping metal by hammering it between flat dies.

- Closed-die forging: Shaping metal by hammering it into a die cavity.

- Impression-die forging: Creating specific shapes or patterns on metal using dies with impressions.

- Coining: Striking metal with a die to create a design or lettering.

- Upsetting: Increasing the diameter or thickness of a metal workpiece by hammering it axially.

6. How do you determine the appropriate heat treatment for a forged part?

- Consider the material composition and properties of the forged part.

- Analyze the desired mechanical properties, such as strength, hardness, and toughness.

- Refer to established heat treatment charts and guidelines for specific materials and applications.

- Conduct trial heat treatments to optimize the process and achieve the desired results.

7. What is the role of dies in drop hammer forging?

- Forming the desired shape and dimensions of the forged part.

- Controlling the flow of metal during the forging process.

- Creating specific patterns or impressions on the forged part.

- Imparting specific mechanical properties to the forged part through heat treatment.

8. How do you select the appropriate dies for a forging operation?

- Consider the shape and dimensions of the desired forged part.

- Choose dies made from materials that can withstand the heat and impact forces involved.

- Select dies that are compatible with the type of forging operation being performed.

- Consult with die manufacturers or engineers to determine the most suitable dies for specific applications.

9. What are the advantages of using a drop hammer for forging?

- High impact force for shaping and forming metal.

- Ability to produce complex shapes and intricate details.

- Improved mechanical properties of forged parts compared to castings or extrusions.

- Versatility in handling various materials and sizes of workpieces.

- Relatively low tooling costs compared to other forging methods.

10. How do you ensure the quality of forged parts produced using a drop hammer?

- Inspect the raw materials and dies for any defects or inconsistencies.

- Calibrate and maintain the drop hammer to ensure accurate and repeatable strikes.

- Monitor the forging process to detect any deviations or abnormalities.

- Conduct non-destructive testing (NDT) or destructive testing to verify the quality and integrity of the forged parts.

- Implement quality control measures throughout the forging process to minimize defects and ensure product consistency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drop Hammer Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drop Hammer Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Drop Hammer Mechanic maintains and repairs drop hammers, which are machines used to shape metal by repeatedly striking it with a heavy weight. Key responsibilities of this role include:

1. Preventive Maintenance

Conduct regular inspections and perform preventive maintenance on drop hammers to ensure optimal operation and prevent breakdowns.

2. Repairs and Troubleshooting

Identify and diagnose faults in drop hammers and execute repairs to restore their functionality and performance.

3. Equipment Calibration

Calibrate drop hammers according to manufacturers’ specifications to ensure precision and accuracy during operation.

4. Safety Compliance

Adhere to safety regulations and maintain a safe work environment by following established procedures and using appropriate protective gear.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some essential tips to help you ace your Drop Hammer Mechanic interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and the specific requirements of the Drop Hammer Mechanic position. This demonstrates your interest and enthusiasm for the opportunity.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your expertise in drop hammer maintenance, repair, and calibration. Share specific examples of your accomplishments that showcase your abilities.

3. Prepare for Technical Questions

Expect technical questions about drop hammer mechanics, troubleshooting techniques, and safety protocols. Prepare answers that demonstrate your knowledge and problem-solving skills.

4. Showcase Your Safety Awareness

Drop hammer operation involves potential hazards. Highlight your commitment to safety by discussing your experience in adhering to safety regulations and implementing safe work practices.

5. Enthusiasm and Motivation

Convey your passion for the field and your eagerness to contribute to the company’s success. Demonstrate your motivation to learn and grow within the organization.

By following these tips and preparing diligently, you can increase your confidence and chances of making a strong impression during your Drop Hammer Mechanic interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Drop Hammer Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.