Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Drop-Wire Builder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Drop-Wire Builder so you can tailor your answers to impress potential employers.

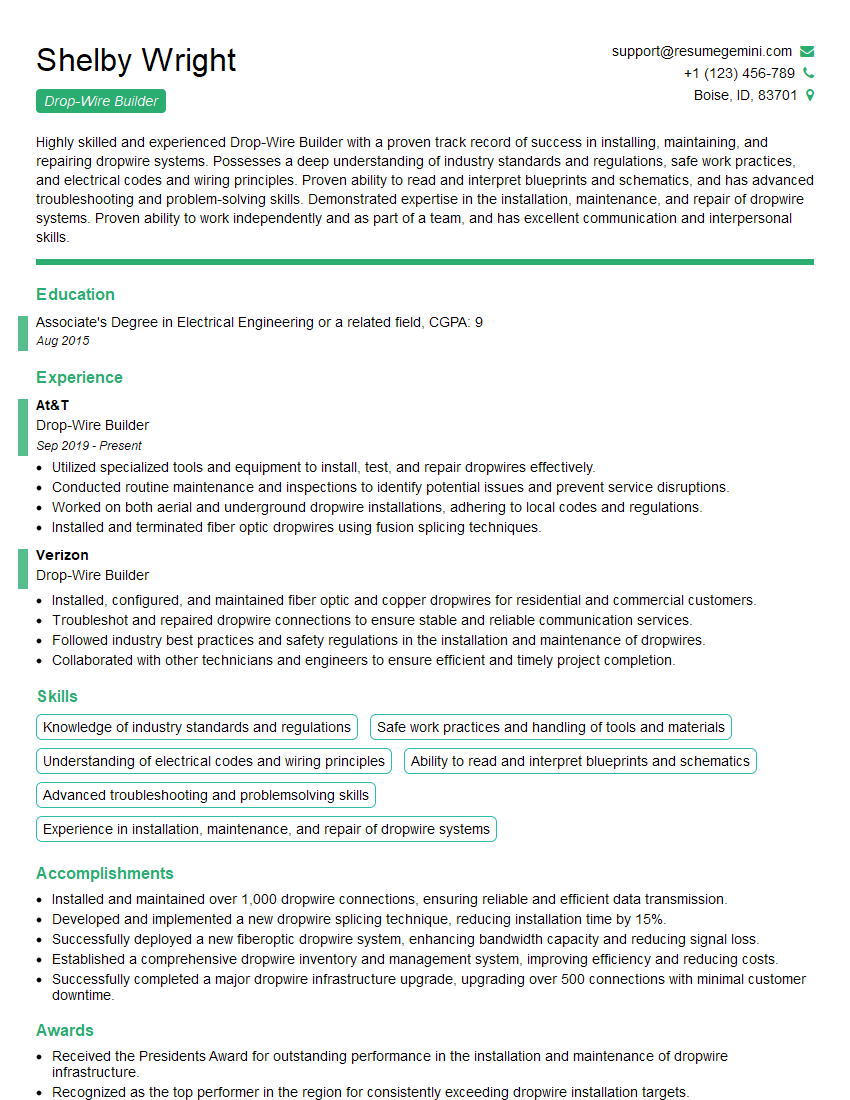

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drop-Wire Builder

1. How do you determine the correct size and type of drop wire to use for a given installation?

To determine the correct size and type of drop wire to use for a given installation, I would consider the following factors:

- Distance: The length of the drop wire run will impact the voltage drop and signal strength. Longer runs require larger gauge wire.

- Number of devices: The number of devices connected to the drop wire will also affect the voltage drop and signal strength. More devices require larger gauge wire.

- Type of service: The type of service being provided (e.g., voice, data, video) will determine the required bandwidth and signal quality. Higher bandwidth services may require larger gauge wire.

- Environmental conditions: The environmental conditions (e.g., temperature, humidity) can affect the performance of the drop wire. Outdoor installations may require weatherproof wire.

2. What is the proper way to install a drop wire clamp?

Securing the Clamp to the Pole

- Position the clamp around the pole and insert the bolt through the holes.

- Tighten the bolt using a wrench or impact driver.

- Ensure that the clamp is securely attached to the pole and will not move.

Attaching the Drop Wire to the Clamp

- Strip approximately 1 inch of insulation from the end of the drop wire.

- Wrap the exposed wire around the hook on the clamp.

- Tighten the screw on the clamp to secure the wire.

- Ensure that the wire is securely fastened and will not slip out of the clamp.

3. How do you troubleshoot a drop wire that is not providing a clear signal?

To troubleshoot a drop wire that is not providing a clear signal, I would follow these steps:

- Inspect the drop wire for any visible damage, such as cuts, breaks, or corrosion.

- Test the continuity of the drop wire using a multimeter to ensure that there are no breaks or shorts.

- Check the connections at the clamp and at the termination point to ensure that they are secure and free of corrosion.

- Isolate the problem by testing each section of the drop wire to determine where the signal loss is occurring.

- Replace any damaged or faulty drop wire or components as necessary.

4. What are the different types of drop wire connectors and when would you use each type?

- IDC (Insulation Displacement Connector): These connectors are used to connect drop wire to terminal blocks or punch-down blocks. They pierce the insulation of the wire without stripping it, making them quick and easy to use.

- Screw-on Connector: These connectors have a screw that is tightened to secure the wire. They are more durable than IDC connectors but require more time to install.

- Crimp Connector: These connectors are crimped onto the wire using a special tool. They provide a secure and reliable connection but require specialized equipment to install.

The type of connector to use depends on the specific application and the desired level of performance and durability.

5. How do you determine the proper tension to apply when installing drop wire?

The proper tension to apply when installing drop wire is critical for ensuring a reliable and long-lasting installation. Too much tension can damage the wire or cause it to sag, while too little tension can allow the wire to move excessively, which can lead to signal loss or damage.

The ideal tension will vary depending on the type and size of drop wire being used, as well as the environmental conditions. However, a general rule of thumb is to apply approximately 25 pounds of tension for every 100 feet of wire.

To determine the proper tension, I would use a tension meter or follow the manufacturer’s recommendations for the specific type of drop wire I am installing.

6. What are the safety precautions that should be taken when working with drop wire?

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Be aware of your surroundings and identify any potential hazards, such as overhead power lines.

- Use proper tools and equipment to safely install and maintain drop wire.

- Follow all manufacturer’s instructions for the safe installation and use of drop wire.

- Never climb a pole or ladder without proper training and equipment.

By following these safety precautions, you can help reduce the risk of accidents and injuries when working with drop wire.

7. What is the difference between aerial and buried drop wire?

Aerial drop wire is designed to be installed overhead, typically on poles or other structures. It is typically made of copper or aluminum and is coated with a weatherproof material to protect it from the elements.

Buried drop wire is designed to be installed underground, directly buried in the soil. It is typically made of copper or aluminum and is coated with a protective jacket to shield it from moisture and other environmental hazards.

The choice between aerial and buried drop wire depends on factors such as the terrain, the presence of overhead obstacles, and the aesthetic considerations of the installation.

8. How do you terminate a drop wire at a network interface device (NID)?

- Prepare the drop wire by stripping approximately 1 inch of insulation from the end.

- Connect the drop wire to the NID by inserting the exposed wires into the appropriate terminals. Ensure that the wires are securely fastened.

- Secure the drop wire to the NID using a cable tie or other suitable method.

- Test the connection to ensure that it is providing a clear signal.

9. What are the advantages of using fiber optic drop wire?

- Higher bandwidth: Fiber optic drop wire can support much higher bandwidth than copper drop wire, making it ideal for high-speed data and video applications.

- Lower signal loss: Fiber optic drop wire has lower signal loss than copper drop wire, resulting in clearer signals over longer distances.

- Lightweight and flexible: Fiber optic drop wire is lightweight and flexible, making it easier to install and handle.

- Immune to electromagnetic interference: Fiber optic drop wire is immune to electromagnetic interference (EMI), which can affect copper drop wire.

10. How do you splice drop wire?

- Prepare the drop wire by stripping approximately 3 inches of insulation from the ends of the wires to be spliced.

- Twist the exposed wires together using a lineman’s pliers or other suitable tool.

- Cover the splice with a heat-shrink tube and heat it using a heat gun to create a waterproof and insulated connection.

- Test the splice to ensure that it is providing a clear signal.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drop-Wire Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drop-Wire Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drop-Wire Builders are responsible for installing, maintaining, and repairing drop wires, which are the wires that connect homes and businesses to the telephone network. Their primary duties include:

1. Installation

Installing new drop wires to connect new customers or replace old ones.

- Determining the best route for the drop wire and securing it to poles, buildings, or other structures.

- Connecting the drop wire to the customer’s premises and testing the connection.

2. Maintenance

Maintaining existing drop wires to ensure they are in good working condition.

- Inspecting drop wires for damage or wear and making repairs as needed.

- Clearing brush and other obstacles from around drop wires to prevent damage.

3. Repair

Repairing damaged or malfunctioning drop wires.

- Identifying the location of the damage and repairing the wire using appropriate tools and materials.

- Testing the repaired wire to ensure it is functioning properly.

4. Documentation

Maintaining accurate records of all work performed.

- Documenting the location of drop wires, the type of work performed, and the materials used.

- Providing customers with copies of work orders and other relevant documentation.

Interview Tips

To prepare for an interview for a Drop-Wire Builder position, it is important to:

1. Research the Company and the Position

Visit the company’s website to learn about their history, values, and current projects. This will help you understand the company’s culture and whether it is a good fit for you.

Review the job description carefully and make note of the key requirements and responsibilities. This will help you tailor your answers to the specific needs of the position.

2. Practice Your Answers to Common Interview Questions

Some common interview questions for Drop-Wire Builders include:

- Tell me about your experience installing, maintaining, and repairing drop wires.

- What are the most important safety precautions to take when working with drop wires?

- How do you troubleshoot and repair common drop wire problems?

Practice answering these questions out loud to improve your confidence and delivery.

3. Highlight Your Skills and Experience

Be sure to emphasize your skills and experience that are relevant to the position. This includes your knowledge of electrical wiring, your experience working with tools and equipment, and your ability to work independently and as part of a team.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the opportunities for professional development within the company?

- What is the company culture like?

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. Be polite and respectful to everyone you meet, including the receptionist and other employees.

6. Follow Up After the Interview

Send a thank-you note to the interviewer within 24 hours of the interview. This is a great opportunity to reiterate your interest in the position and thank the interviewer for their time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Drop-Wire Builder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.