Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Drum Builder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

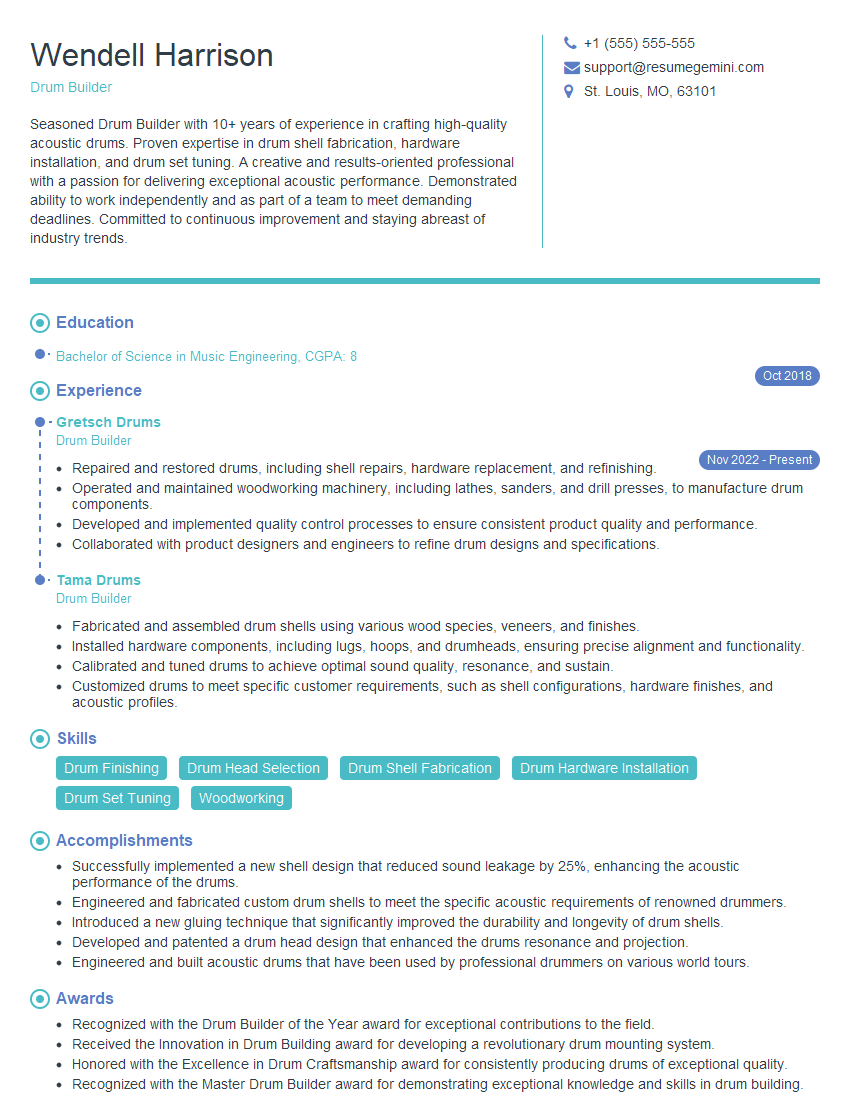

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drum Builder

1. What are the key considerations when selecting materials for drum shells?

When selecting materials for drum shells, several key considerations must be taken into account:

- Tone: Different materials produce distinct tonal characteristics. Woods, for example, provide warm, resonant tones, while metal shells offer brighter, more articulate sounds.

- Strength and durability: Drum shells must withstand the impact of drum sticks and the tension of drumheads. Materials such as maple, birch, and mahogany offer excellent strength and durability for drum shells.

- Weight: The weight of the drum shell affects its portability and the overall weight of the drum kit. Lightweight materials like balsa wood can reduce the weight of the drum, while heavier materials like metal provide more sustain and resonance.

- Cost: The cost of the material is also a significant consideration. Exotic woods and high-end materials can be expensive, while more common woods offer a more affordable option.

2. Describe the process of shaping and bending drum shells.

Steam Bending

- Involves applying steam to the wood to make it pliable and bendable.

- The wood is placed in a steam box or chamber and exposed to high levels of humidity and temperature.

- Once the wood becomes pliable, it is bent around a mold or form to achieve the desired shape.

Vacuum Pressing

- Uses a vacuum press to apply pressure to the wood, forcing it into the desired shape.

- The wood is placed between a mold and a vacuum bag.

- The vacuum bag is sealed and a vacuum is applied, creating negative pressure that draws the wood into the mold.

3. Explain the importance of proper bearing edge preparation for drum shells.

Proper bearing edge preparation is crucial for achieving optimal sound and performance from a drum shell:

- Sound quality: The bearing edge is where the drumhead makes contact with the shell, and its shape and precision directly affect the tone and resonance of the drum.

- Drumhead seating: A well-prepared bearing edge ensures that the drumhead sits evenly and securely on the shell, preventing unwanted vibrations and ensuring proper tuning.

- Durability: A rounded or beveled bearing edge reduces stress on the drumhead and shell, enhancing the durability of both components.

4. Describe the different methods used to reinforce drum shells for added strength.

- Reinforcing hoops: Metal hoops are placed around the circumference of the drum shell, providing additional support and preventing the shell from warping or denting.

- Lug casings: Lug casings are metal plates that are inserted into the shell and provide a solid mounting point for drum lugs. They distribute the tension of the drumheads evenly across the shell.

- Internal reinforcements: Internal reinforcements, such as plywood rings or cross-bracing, can be added inside the shell to increase its strength and rigidity.

5. Discuss the factors that influence the choice of drum hardware, such as lugs, hoops, and tension rods.

- Material: The material used for drum hardware components affects their weight, durability, and cost. Steel is a common and affordable option, while aluminum and titanium offer lighter weight and higher strength.

- Design: The design of the hardware can impact its functionality and ease of use. Lugs with quick-release mechanisms allow for faster drumhead changes, while hoops with rounded edges prevent damage to the drumhead.

- Compatibility: When choosing drum hardware, it is essential to ensure compatibility with the drum shell and other components. The size and spacing of lugs and hoops must match the specific drum model.

6. Explain the process of tuning drums and the factors that affect the sound.

Tuning drums involves adjusting the tension of the drumheads to achieve the desired pitch and sound:

- Tension adjustment: The tension of the drumheads is adjusted using tension rods. Tightening the rods increases the tension, raising the pitch, while loosening the rods decreases the tension, lowering the pitch.

- Factors affecting sound: The sound of the drum is influenced by factors such as the size and depth of the drum, the type of drumhead used, and the amount of damping applied.

7. Describe the different types of drum finishes and their impact on the sound and appearance of the drum.

- Lacquer: A clear or colored finish that provides a glossy, protective coating. Lacquer finishes enhance the natural grain of the wood and offer a classic look.

- Wrap: A thin, decorative film that is applied to the drum shell. Wraps are available in a wide range of colors and patterns, allowing for customization of the drum’s appearance.

- Stain: A penetrating finish that colors the wood and highlights its natural grain. Stains provide a more subtle finish compared to lacquer or wraps.

8. Discuss the role of drum heads in the overall sound and performance of the drum.

- Tone: Drumheads contribute significantly to the tone of the drum. Different materials and thicknesses of drumheads produce distinct sounds and respond differently to different playing styles.

- Attack and sustain: The attack and sustain of the drum are also affected by the drumhead. Thinner heads provide a quicker attack and shorter sustain, while thicker heads offer a slower attack and longer sustain.

- Durability: The durability of the drumhead is important for maintaining optimal sound and performance. Drumheads can wear out over time and need to be replaced periodically.

9. Explain the process of designing and prototyping a new drum model.

Designing and prototyping a new drum model involves several steps:

- Conceptualization: The first step is to conceptualize the design, considering factors such as the desired sound, materials, and hardware.

- Prototyping: Once the design is conceptualized, a prototype is built to test the concept and make necessary adjustments.

- Testing and evaluation: The prototype is tested by drummers and feedback is gathered to refine the design further.

- Production: After the prototype is finalized, the drum model is ready for production.

10. Describe the quality control measures implemented to ensure the consistency and reliability of drum products.

- Material inspection: Raw materials, such as wood and metal, are inspected to ensure they meet the required standards for quality and consistency.

- Process monitoring: The manufacturing process is closely monitored to ensure that all steps are followed correctly and that the product meets the desired specifications.

- Testing: Finished drums undergo rigorous testing to evaluate their sound, durability, and performance.

- Documentation: All quality control measures and test results are documented to ensure traceability and accountability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drum Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drum Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drum Builders are responsible for the assembly, maintenance, and repair of drums and related equipment used in the music industry.

1. Assembly and Fabrication

Assemble and fabricate drums, including shells, hoops, lugs, and other components.

- Follow blueprints and specifications to construct drums of various sizes and types.

- Use specialized tools and equipment to cut, shape, and join materials.

2. Installation and Maintenance

Install and maintain drums in performance venues, recording studios, and other settings.

- Set up and tune drums to meet specific requirements.

- Perform routine inspections and maintenance to ensure optimal performance.

3. Repair and Restoration

Repair and restore damaged or malfunctioning drums.

- Diagnose problems and determine appropriate repair methods.

- Replace or repair damaged components, such as shells, hoops, or hardware.

4. Material Selection and Sourcing

Select and source high-quality materials for drum construction.

- Research and evaluate different types of wood, metal, and other materials.

- Establish relationships with suppliers to ensure timely delivery of materials.

Interview Tips

Preparing for a Drum Builder interview requires a combination of technical knowledge and enthusiasm for the craft. Here are some tips to help you ace the interview and demonstrate your qualifications:

1. Research the Company and Role

Before the interview, thoroughly research the company’s history, products, and commitment to quality.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and articles to stay abreast of current trends.

2. Highlight Your Skills and Experience

Emphasize your skills in drum assembly, fabrication, repair, and maintenance.

- Quantify your experience by providing specific examples of projects you’ve worked on.

- Showcase your knowledge of different types of drums, materials, and construction techniques.

3. Show Your Passion for the Craft

Let the interviewer know that you are genuinely passionate about drum building.

- Share your personal experiences with drums and explain why you enjoy working with them.

- Discuss your understanding of the importance of drums in music and the role they play in performance.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to your skills, experience, and motivation.

- Tell us about your experience in assembling and repairing drums.

- Describe a challenging drum building project you’ve worked on.

- Why are you interested in working as a Drum Builder?

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest in the company and the role.

- Inquire about the company’s commitment to innovation and product development.

- Ask about the potential for growth and advancement within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Drum Builder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Drum Builder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.