Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Drum Drier Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Drum Drier Operator so you can tailor your answers to impress potential employers.

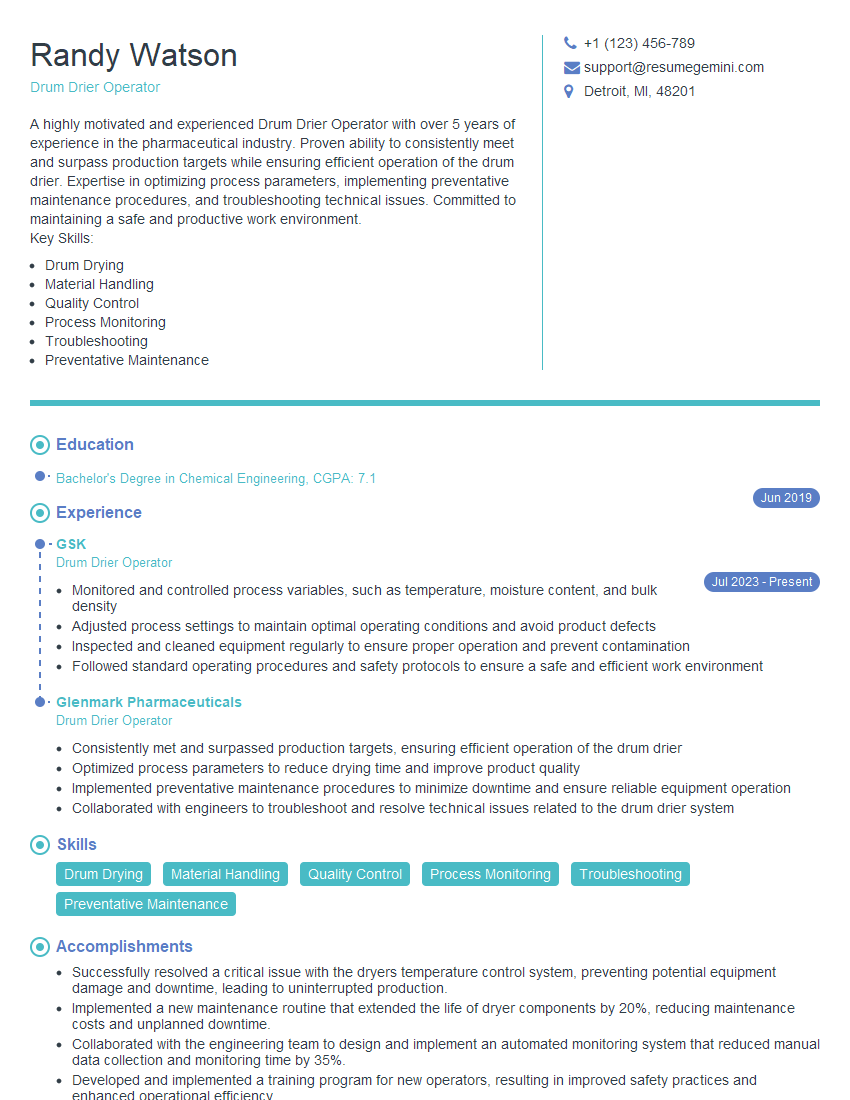

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drum Drier Operator

1. Describe the key responsibilities of a Drum Drier Operator?

- Monitor and control the operation of drum dryers to ensure efficient and safe drying of materials

- Adjust operating parameters such as temperature, feed rate, and drum speed to optimize drying process

- Inspect and maintain drum dryers, including cleaning, lubrication, and replacement of worn parts

- Troubleshoot and resolve operational issues to minimize downtime and ensure smooth production

- Follow safety protocols and maintain a clean and organized work environment

2. Explain the different types of drum dryers and their applications?

Types of Drum Dryers:

- Direct Heat Dryers: Heat is directly applied to the material through the drum wall

- Indirect Heat Dryers: Heat is transferred to the material through a heat transfer medium, such as steam or hot air

Applications:

- Direct Heat Dryers: Suitable for materials that can withstand high temperatures, such as sand, minerals, and chemicals

- Indirect Heat Dryers: Used for drying heat-sensitive materials, such as food products, pharmaceuticals, and paper

3. Describe the key performance indicators (KPIs) used to measure the effectiveness of a Drum Drier Operator?

- Product quality and moisture content

- Production efficiency and throughput

- Energy consumption and cost

- Downtime and maintenance costs

- Safety and compliance

4. How do you ensure the safety and proper operation of drum dryers?

- Follow established safety protocols and guidelines

- Inspect and maintain equipment regularly to prevent breakdowns

- Identify and eliminate potential hazards in the work environment

- Operate equipment within specified parameters to avoid accidents

- Report any safety concerns or incidents promptly to supervisors

5. Describe a situation where you had to troubleshoot and resolve an issue with a drum dryer?

- Identified the problem as a faulty temperature sensor

- Replaced the sensor and recalibrated the system

- Monitored the dryer’s performance to ensure the issue was resolved

- Documented the troubleshooting process and findings for future reference

6. How do you stay up-to-date on the latest technologies and best practices in drum drying?

- Attend industry conferences and workshops

- Read technical journals and articles

- Network with other professionals in the field

- Participate in training programs offered by equipment manufacturers

7. What areas do you see for improvement in the drum drying process at our facility?

- Upgrade to more energy-efficient equipment

- Implement automated control systems to optimize performance

- Improve maintenance practices to reduce downtime

- Train operators on the latest drying techniques

8. How do you ensure that the dried material meets the required specifications?

- Monitor drying parameters and make adjustments as needed

- Perform regular quality control checks on the dried material

- Calibrate testing equipment to ensure accuracy

- Document all quality control data and maintain records

9. How do you work effectively as part of a team in a production environment?

- Communicate clearly and collaborate with colleagues

- Share knowledge and expertise to support team goals

- Assist other team members when needed

- Maintain a positive and supportive work environment

10. How would you handle a situation where a conflict arises between quality and production goals?

- Prioritize safety and product quality above production targets

- Communicate the issue to supervisors and seek guidance

- Explore alternative solutions that meet both quality and production requirements

- Document the decision-making process for future reference

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drum Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drum Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drum Drier Operators play a pivotal role in industrial settings, ensuring the efficient and safe operation of drum driers used in various industries. Key responsibilities include:

1. Equipment Operation

Operate and monitor drum driers to dry and process materials such as minerals, chemicals, and food products.

- Control temperature, speed, and other operating parameters.

- Monitor product flow and ensure optimal drying conditions.

2. Quality Control

Maintain product quality by monitoring moisture content, particle size, and other specifications.

- Conduct routine testing and make necessary adjustments.

- Ensure compliance with quality standards.

3. Production Optimization

Maximize production efficiency and minimize downtime.

- Identify and address potential issues.

- Implement process improvements.

4. Equipment Maintenance

Perform routine maintenance and repairs to ensure optimal equipment performance.

- Lubricate and clean components.

- Replace worn or damaged parts promptly.

5. Safety and Compliance

Adhere to safety regulations and guidelines.

- Follow established procedures.

- Report any safety concerns.

Interview Preparation Tips

To ace the interview for a Drum Drier Operator position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s business, products, and industry trends.

- Visit the company website and read industry news.

- Network with professionals in the field.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating and maintaining drum driers.

- Quantify your accomplishments using specific examples.

- Showcase your problem-solving abilities and attention to detail.

3. Prepare for Technical Questions

Anticipate questions about drum drier operation, quality control procedures, and safety protocols.

- Review technical manuals and industry best practices.

- Practice answering questions about troubleshooting and optimization techniques.

4. Demonstrate Safety Awareness

Convey your commitment to workplace safety.

- Explain your experience with safety regulations and protocols.

- Share examples of how you have ensured safety in previous roles.

5. Be Professional and Enthusiastic

Present yourself professionally and express your enthusiasm for the role.

- Dress appropriately and arrive punctually.

- Be respectful, ask thoughtful questions, and demonstrate a willingness to learn.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Drum Drier Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Drum Drier Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.