Are you gearing up for a career in Dry Boss? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dry Boss and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

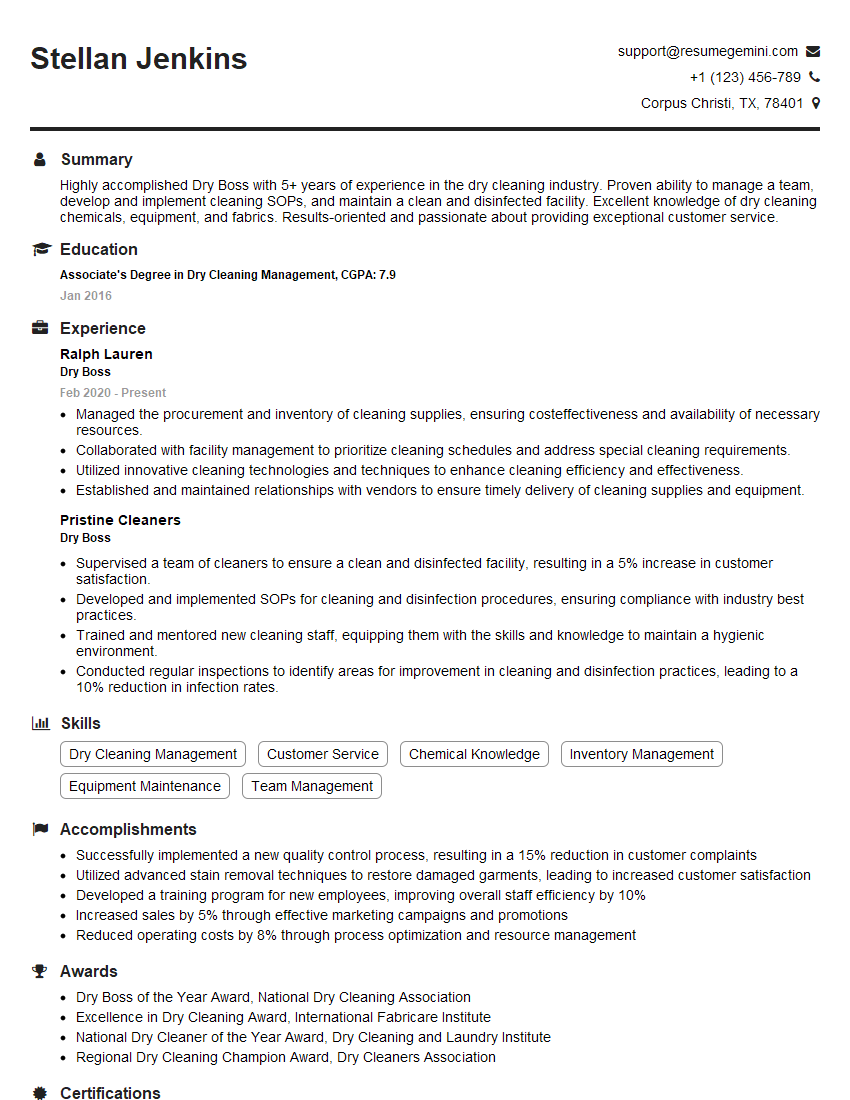

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Boss

1. Describe the key responsibilities of a Dry Boss?

As a Dry Boss, I would be responsible for overseeing the overall drying operations of the facility, ensuring that products meet quality standards and production targets are met. My key responsibilities would include:

- Developing and implementing drying processes and procedures

- Supervising and training staff on drying operations

- Monitoring and maintaining drying equipment

- Troubleshooting and resolving drying issues

- Ensuring compliance with safety and environmental regulations

2. What are the different types of drying methods used in the industry?

There are several types of drying methods used in the industry, each with its own advantages and disadvantages. Some common methods include:

Convection Drying

- Uses heated air or gas to remove moisture from the product

- Suitable for drying products with high moisture content

Conduction Drying

- Transfers heat directly to the product through contact with a heated surface

- Suitable for drying products that are heat-sensitive or have low moisture content

Radiation Drying

- Uses electromagnetic waves to generate heat within the product

- Suitable for drying products that are sensitive to other drying methods

Freeze Drying

- Removes moisture from a frozen product by sublimation

- Suitable for drying products that are heat-sensitive or require preservation of their original structure

3. What factors influence the selection of a drying method?

The selection of a drying method depends on various factors, including:

- Product characteristics (moisture content, heat sensitivity, structure)

- Desired drying rate and capacity

- Energy efficiency and cost

- Environmental regulations

- Space availability

4. How do you optimize drying efficiency while maintaining product quality?

Optimizing drying efficiency while maintaining product quality involves balancing various factors:

- Selecting the appropriate drying method and equipment

- Optimizing drying parameters (temperature, humidity, airflow)

- Monitoring and controlling drying conditions

- Implementing proper loading and unloading techniques

- Regular maintenance and calibration of equipment

- Training and supervising staff on best practices

5. What are the common challenges faced in drying operations and how do you overcome them?

Common challenges in drying operations include:

Product sticking or caking

- Optimizing drying conditions (temperature, humidity)

- Using anti-caking agents or surface treatments

Over-drying or under-drying

- Monitoring and controlling drying parameters

- Implementing automated control systems

Energy inefficiency

- Selecting energy-efficient drying equipment

- Optimizing drying processes and reducing waste

6. Describe the safety measures and regulations that must be followed in drying operations?

Safety in drying operations is paramount, and various measures and regulations must be followed, including:

- Proper ventilation to prevent accumulation of flammable vapors

- Fire prevention and suppression systems

- Regular equipment inspections and maintenance

- Training and safety protocols for staff

- Compliance with OSHA and other regulatory standards

7. What quality control measures are implemented in drying operations?

Quality control measures in drying operations are crucial to ensure product consistency and meet customer specifications. These measures include:

- Establishing drying standards and specifications

- Regular product testing and analysis

- Monitoring drying parameters and equipment performance

- Recordkeeping and documentation to demonstrate compliance

- Continuous improvement and optimization of drying processes

8. What are the recent advancements and trends in drying technology?

The drying industry is constantly evolving, with new technologies and innovations emerging. Some recent advancements include:

- Development of energy-efficient and sustainable drying methods

- Integration of automation and control systems

- Advanced monitoring and data analytics for process optimization

- Exploration of novel drying techniques, such as microwave and infrared drying

- Focus on research and development to improve product quality and efficiency

9. How do you stay updated on the latest developments and best practices in drying technology?

To stay updated on the latest developments and best practices in drying technology, I:

- Attend industry conferences and exhibitions

- Read technical journals and industry publications

- Participate in online forums and discussion groups

- Network with other professionals in the field

- Engage in continuous professional development and training

10. Describe a situation where you successfully resolved a complex issue in a drying operation?

In my previous role, we encountered an issue where a particular product was experiencing inconsistent drying results. After thorough investigation, we identified that the root cause was a malfunctioning temperature sensor in the drying chamber. By promptly replacing the faulty sensor and recalibrating the equipment, we resolved the issue and ensured consistent product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Boss.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Boss‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Dry Boss is responsible for overseeing the setup, operation, maintenance, and repair of the dry-cleaning machinery and processes. Other key responsibilities include:

1. Daily Operations Management

Ensuring smooth processing of clothes from initial quality check through the dry cleaning process to final inspection and packaging

- Assigning tasks to operators and monitoring their performance

- Identifying and resolving production bottlenecks and breakdowns

2. Equipment Management

Maintaining all dry-cleaning equipment, including washing machines, dryers, and presses

- Conducting regular inspections and preventive maintenance

- Troubleshooting and repairing equipment malfunctions

3. Chemical Management

Managing the inventory and handling of dry-cleaning chemicals

- Monitoring chemical levels and making adjustments as needed

- Ensuring safe and compliant disposal of spent chemicals

4. Quality Control

Ensuring the quality of dry-cleaned garments

- Inspecting garments before and after cleaning

- Addressing customer concerns and complaints

Interview Tips

To ace an interview for a Dry Boss position, it is essential to demonstrate your technical expertise, leadership skills, and commitment to quality.

1. Research the Company and Role

Familiarize yourself with the dry-cleaning industry, the company’s history and processes, and the specific responsibilities of the Dry Boss.

- Visit the company’s website and review any relevant information.

- Network with professionals in the industry to gain insights.

2. Highlight Your Technical Skills

Emphasize your experience in dry-cleaning operations, equipment maintenance, and chemical handling.

- Provide specific examples of how you have resolved equipment issues or improved cleaning processes.

- Quantify your achievements whenever possible, using metrics such as increased productivity or reduced downtime.

3. Demonstrate Leadership and Problem-Solving Abilities

Showcase your ability to lead and motivate a team, solve problems effectively, and make sound decisions.

- Share examples of how you have successfully managed a team and handled challenging situations in a dry-cleaning environment.

- Explain how you approach problem-solving and decision-making in a systematic and analytical manner.

4. Emphasize Your Quality Orientation

Convince the interviewer that you are committed to delivering high-quality results.

- Describe your understanding of quality standards and your experience in implementing quality control measures.

- Share examples of how you have gone above and beyond to meet customer expectations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dry Boss interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!