Feeling lost in a sea of interview questions? Landed that dream interview for Dry Box Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dry Box Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

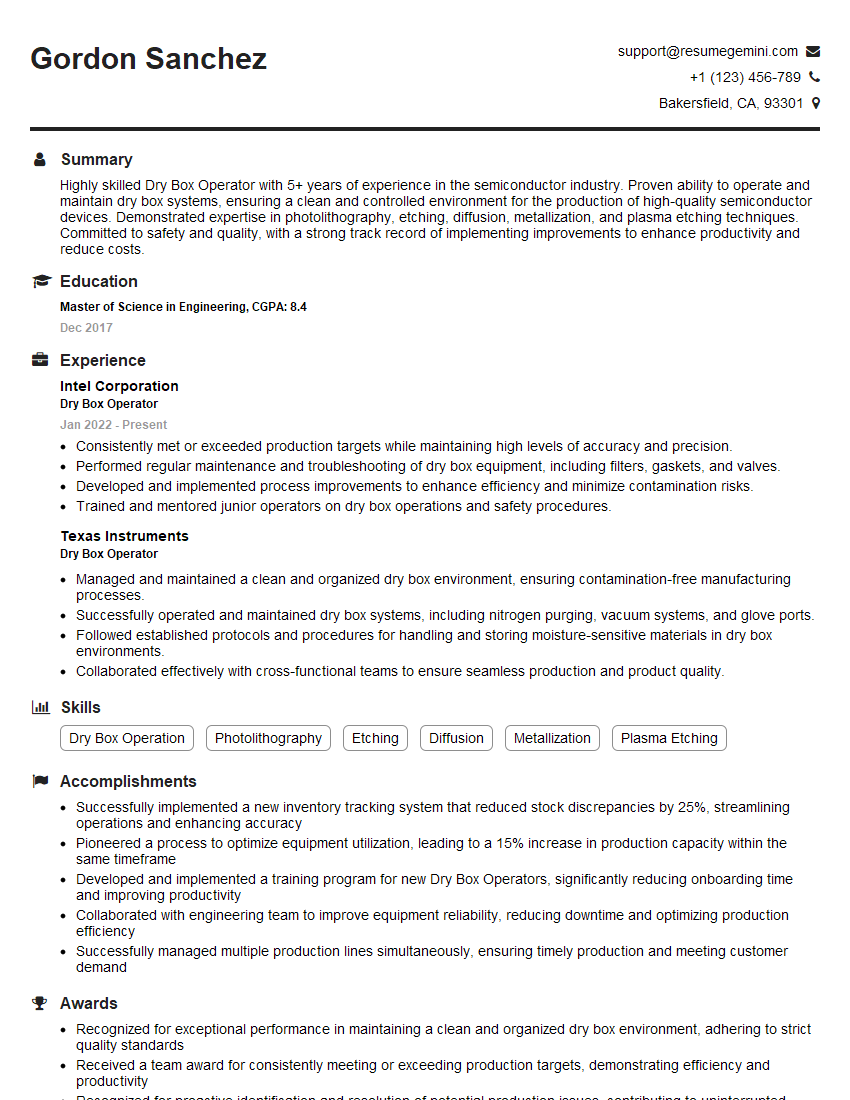

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Box Operator

1. What is the role of a dry box operator?

As a Dry Box Operator, my responsibilities include:

- Maintaining a clean and dry environment within the dry box

- Handling and transferring moisture-sensitive materials

- Operating and maintaining dry box equipment

- Ensuring that all materials are properly stored and labeled

- Following all safety procedures and protocols

2. What are the key skills required to be a successful dry box operator?

To be successful in this role, I believe the key skills required are:

- Attention to detail

- Strong organizational skills

- Ability to work independently and as part of a team

- Understanding of dry box equipment and procedures

- Commitment to safety

3. What are the different types of dry boxes and their applications?

There are several types of dry boxes, each designed for specific applications. Some common types include:

- Desiccator Dry Boxes: Used for storing and handling moisture-sensitive materials, such as electronics and chemicals

- Nitrogen Dry Boxes: Used for storing and handling materials that are sensitive to oxygen and moisture, such as semiconductors and metals

- Purge Dry Boxes: Used for storing and handling materials that are sensitive to moisture, but can tolerate some oxygen exposure

4. How do you ensure the dryness of the environment within a dry box?

To ensure the dryness of the environment within a dry box, I follow several key steps:

- Regularly monitoring the humidity levels using a hygrometer

- Using desiccants to absorb moisture from the air

- Maintaining a positive pressure inside the dry box to prevent outside air from entering

- Purging the dry box with dry nitrogen or argon gas

5. What are the safety precautions that must be taken when working with a dry box?

When working with a dry box, it is crucial to follow these safety precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses

- Ensure that the dry box is properly grounded to prevent electrostatic discharge

- Do not store flammable materials inside the dry box

- Be aware of the potential for oxygen depletion and take necessary precautions

- Follow all established safety protocols and procedures

6. What are the common problems that can occur with dry boxes and how do you troubleshoot them?

Some common problems that can occur with dry boxes include:

- High humidity levels: Can be caused by leaks in the dry box, malfunctioning desiccants, or improper purging

- Oxygen contamination: Can be caused by leaks in the dry box or improper purging

- Equipment malfunctions: Can be caused by power outages, faulty components, or improper maintenance

To troubleshoot these problems, I would:

- Check for leaks in the dry box using a leak detector

- Replace or regenerate the desiccants

- Inspect and test the dry box equipment

- Consult the manufacturer’s instructions or seek professional assistance if necessary

7. How do you handle and transfer moisture-sensitive materials in a dry box?

To handle and transfer moisture-sensitive materials in a dry box, I follow these steps:

- Use clean and dry tweezers or gloves

- Minimize exposure to the outside environment

- Transfer materials quickly and efficiently

- Store materials in appropriate containers or bags

- Label materials clearly and accurately

8. What are the maintenance procedures for a dry box?

To maintain a dry box, I perform the following procedures:

- Regularly clean the interior and exterior of the dry box

- Replace or regenerate the desiccants as needed

- Inspect and test the equipment, including the seals, valves, and sensors

- Calibrate the hygrometer to ensure accurate humidity readings

- Follow the manufacturer’s instructions for any specific maintenance requirements

9. How do you ensure the quality of materials stored in a dry box?

To ensure the quality of materials stored in a dry box, I:

- Monitor the humidity and oxygen levels regularly

- Inspect materials for any signs of damage or contamination

- Follow proper storage procedures, such as using airtight containers and labels

- Document all activities related to the storage and handling of materials

10. How do you stay up-to-date on the latest advancements in dry box technology?

To stay up-to-date on the latest advancements in dry box technology, I:

- Attend industry conferences and exhibitions

- Read technical journals and articles

- Network with other dry box operators and experts

- Participate in training and certification programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Box Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Box Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dry Box Operators play a crucial role in semiconductor manufacturing by maintaining contamination-controlled environments essential for delicate fabrication processes. Their primary responsibilities include:

1. Environment Monitoring

Continuously monitor the dry box environment for critical parameters such as temperature, humidity, and particle count.

- Calibrate and maintain monitoring equipment.

- Document and report any deviations from established limits.

2. Material Handling

Safely and carefully handle sensitive materials, wafers, and photomasks within the dry box.

- Perform material transfers between dry boxes and cleanroom areas.

- Ensure proper storage and retrieval of materials.

Equipment Operation

Operate and maintain dry box equipment, including air filtration systems, vacuum pumps, and process tools.

- Perform routine maintenance and troubleshooting.

- Follow established procedures for equipment setup and shutdown.

4. Process Support

Provide technical support to process engineers and other team members.

- Assist in troubleshooting and resolving process issues.

- Maintain detailed process documentation for audits and quality control purposes.

Interview Tips

To ace your interview for a Dry Box Operator position, consider the following tips:

1. Research the Company and Position

Thoroughly research the company’s products, services, and culture. Read the job description carefully to identify the specific requirements and responsibilities.

- Prepare questions about the company’s operations and the role of the Dry Box Operator.

- Highlight your understanding of the industry and your interest in the position.

2. Emphasize Technical Skills

Demonstrate your proficiency in operating and maintaining dry box equipment. Provide specific examples of your experience in handling sensitive materials and maintaining cleanroom environments.

- Quantify your accomplishments whenever possible, providing metrics that showcase your effectiveness.

- Be prepared to discuss your knowledge of air filtration systems, vacuum pumps, and process tools.

3. Communication and Teamwork

Highlight your communication and teamwork skills, as Dry Box Operators often collaborate with engineers and other team members. Provide examples of your ability to effectively communicate technical information and work in a collaborative setting.

- Discuss your experience in troubleshooting and resolving process issues.

- Emphasize your attention to detail and commitment to following established procedures.

4. Problem-Solving Ability

Demonstrate your problem-solving abilities and your approach to handling unexpected situations in a controlled environment. Provide examples of how you have identified and resolved issues impacting the quality or efficiency of manufacturing processes.

- Highlight your analytical skills and your ability to think critically under pressure.

- Be prepared to discuss your decision-making process and how you prioritize tasks in a demanding environment.

Next Step:

Now that you’re armed with the knowledge of Dry Box Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Dry Box Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini