Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dry Cell Assembly Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

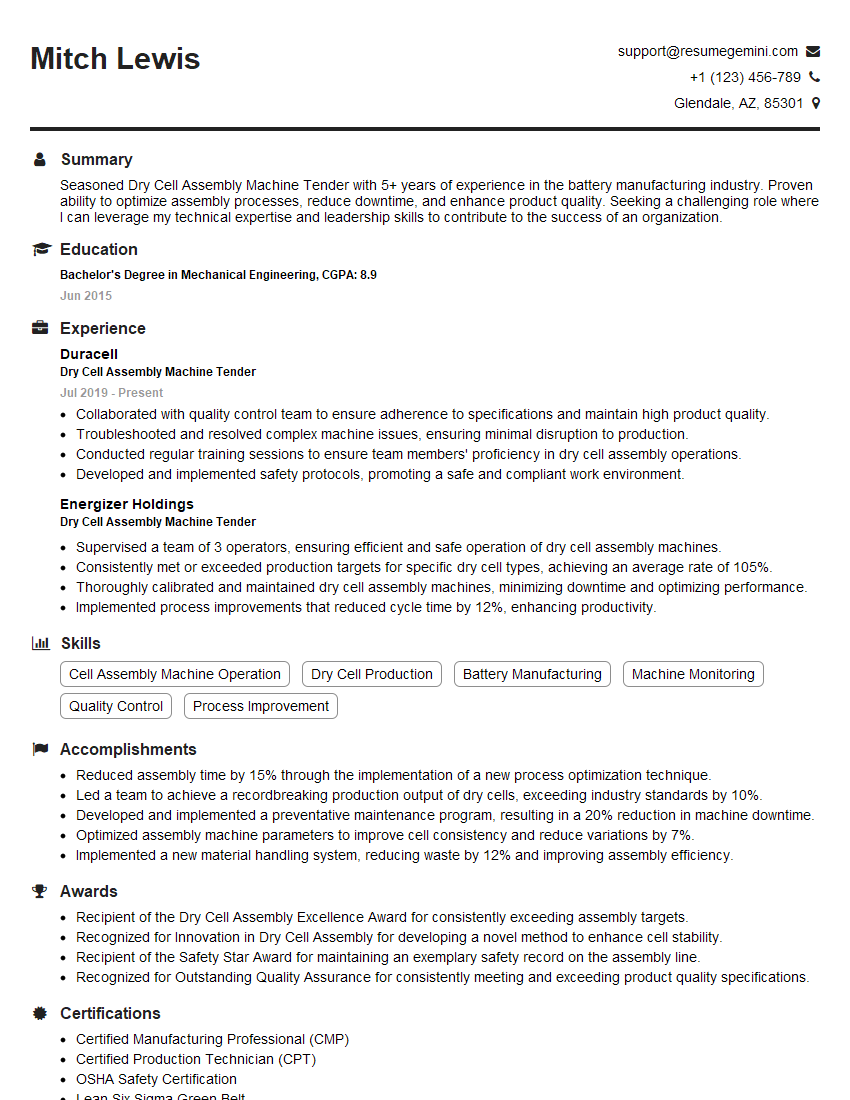

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Cell Assembly Machine Tender

1. Describe the steps involved in dry cell assembly.

The steps involved in dry cell assembly include:

- Preparing the cell components (e.g., electrodes, separators, and electrolyte)

- Assembling the cell components into a cylindrical shape

- Inserting the assembled cell into a metal can

- Crimping and sealing the can

- Inspecting and testing the finished cell

2. What are the different types of dry cells and their applications?

Leclanché cell

- Zinc-carbon battery

- Primary battery

- Used in low-drain devices (e.g., clocks, flashlights)

Alkaline battery

- Zinc-manganese dioxide battery

- Primary battery

- Used in medium-drain devices (e.g., toys, cameras)

Lithium battery

- Lithium-ion battery

- Rechargeable battery

- Used in high-drain devices (e.g., laptops, smartphones)

3. What are the key parameters that affect the performance of a dry cell?

- Chemical composition of the electrodes and electrolyte

- Physical structure of the cell (e.g., size, shape, electrode spacing)

- Environmental conditions (e.g., temperature, humidity)

4. Describe the process of testing dry cells for quality and performance.

Testing dry cells for quality and performance typically involves:

- Visual inspection for defects

- Electrical tests (e.g., voltage, capacity, leakage current)

- Performance tests under different operating conditions (e.g., temperature, load)

5. What are the safety precautions that should be taken when handling and using dry cells?

- Avoid short-circuiting the terminals

- Do not disassemble or puncture the cells

- Dispose of used cells properly

- Keep out of reach of children

6. Describe the troubleshooting steps for a dry cell assembly machine that is not functioning properly.

Troubleshooting steps for a dry cell assembly machine that is not functioning properly may include:

- Checking the power supply and connections

- Inspecting the mechanical components for wear and tear

- Calibrating the sensors and controls

- Cleaning and lubricating the machine

- Replacing faulty components

7. How do you ensure that the dry cells produced by your machine meet the required specifications?

- Regularly monitoring the machine’s performance

- Conducting quality control checks on the finished cells

- Making adjustments to the machine or process as needed

- Maintaining a clean and organized work area

8. What is the importance of preventive maintenance for dry cell assembly machines?

Preventive maintenance is important for dry cell assembly machines to:

- Reduce the risk of breakdowns

- Extend the life of the machine

- Improve the quality of the finished cells

- Reduce downtime and production costs

9. What is your experience with different types of dry cell assembly machines?

I have experience with a variety of dry cell assembly machines, including:

- Manual machines

- Semi-automatic machines

- Fully automatic machines

I am also familiar with the different types of dry cells that can be produced on these machines, such as alkaline batteries and lithium batteries.

10. What are your strengths and weaknesses as a Dry Cell Assembly Machine Tender?

Strengths

- Strong attention to detail

- Ability to work quickly and efficiently

- Experience with a variety of dry cell assembly machines

- Commitment to quality and safety

Weaknesses

- Limited experience with troubleshooting complex machine problems

- Not yet fully proficient in the use of all the different types of dry cell assembly machines

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Cell Assembly Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Cell Assembly Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dry Cell Assembly Machine Tender is responsible for operating and maintaining dry cell assembly machines. They ensure that the machines are running smoothly and that the dry cells are assembled correctly.

1. Machine Operation

The primary responsibility of a Dry Cell Assembly Machine Tender is to operate the dry cell assembly machines. This involves loading the machines with raw materials, monitoring the assembly process, and unloading the finished products.

- Load the machines with raw materials, such as electrodes, separators, and electrolytes.

- Monitor the assembly process to ensure that the cells are being assembled correctly.

- Unload the finished products and inspect them for defects.

2. Machine Maintenance

In addition to operating the machines, Dry Cell Assembly Machine Tenders are also responsible for maintaining them. This involves cleaning the machines, lubricating the moving parts, and making minor repairs.

- Clean the machines on a regular basis to remove dust and debris.

- Lubricate the moving parts of the machines to prevent wear and tear.

- Make minor repairs to the machines, such as replacing worn parts.

3. Quality Control

Dry Cell Assembly Machine Tenders are also responsible for ensuring that the dry cells meet the required quality standards. This involves inspecting the cells for defects and testing them to ensure that they meet the required performance specifications.

- Inspect the cells for defects, such as cracks or leaks.

- Test the cells to ensure that they meet the required performance specifications.

- Reject cells that do not meet the required quality standards.

4. Safety

Dry Cell Assembly Machine Tenders must also follow all safety procedures and regulations. This includes wearing appropriate safety gear, such as gloves and safety glasses, and following all lockout/tagout procedures.

- Wear appropriate safety gear, such as gloves and safety glasses.

- Follow all lockout/tagout procedures.

- Report any safety hazards to the supervisor.

Interview Tips

To ace an interview for a Dry Cell Assembly Machine Tender position, it is important to prepare and practice your answers to common interview questions. Here are a few tips to help you prepare for your interview:

1. Research the Company and the Position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the position.

- Visit the company’s website to learn about their history, mission, and products.

- Read online reviews of the company to get a sense of the company culture.

- Review the job posting to understand the specific requirements of the position.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Write down your answers to common interview questions.

- Practice answering your questions out loud.

- Ask a friend or family member to role-play an interview with you.

3. Be Prepared to Talk About Your Experience

The interviewer will likely ask you about your experience in operating and maintaining dry cell assembly machines. Be prepared to discuss your specific skills and experience, and how they relate to the requirements of the position.

- Quantify your experience whenever possible. For example, “I have operated dry cell assembly machines for over 5 years, and I have assembled over 1 million cells in that time.”

- Highlight your skills and experience that are most relevant to the position you are applying for.

- Use examples to illustrate your skills and experience.

4. Be Enthusiastic and Positive

The interviewer is looking for someone who is enthusiastic about the position and who is a good fit for the company culture. Be yourself, and let the interviewer see your passion for the job.

- Smile and make eye contact with the interviewer.

- Be enthusiastic and positive about the position and the company.

- Thank the interviewer for their time.

Next Step:

Now that you’re armed with the knowledge of Dry Cell Assembly Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Dry Cell Assembly Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini