Are you gearing up for an interview for a Dry Cell Battery Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Dry Cell Battery Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

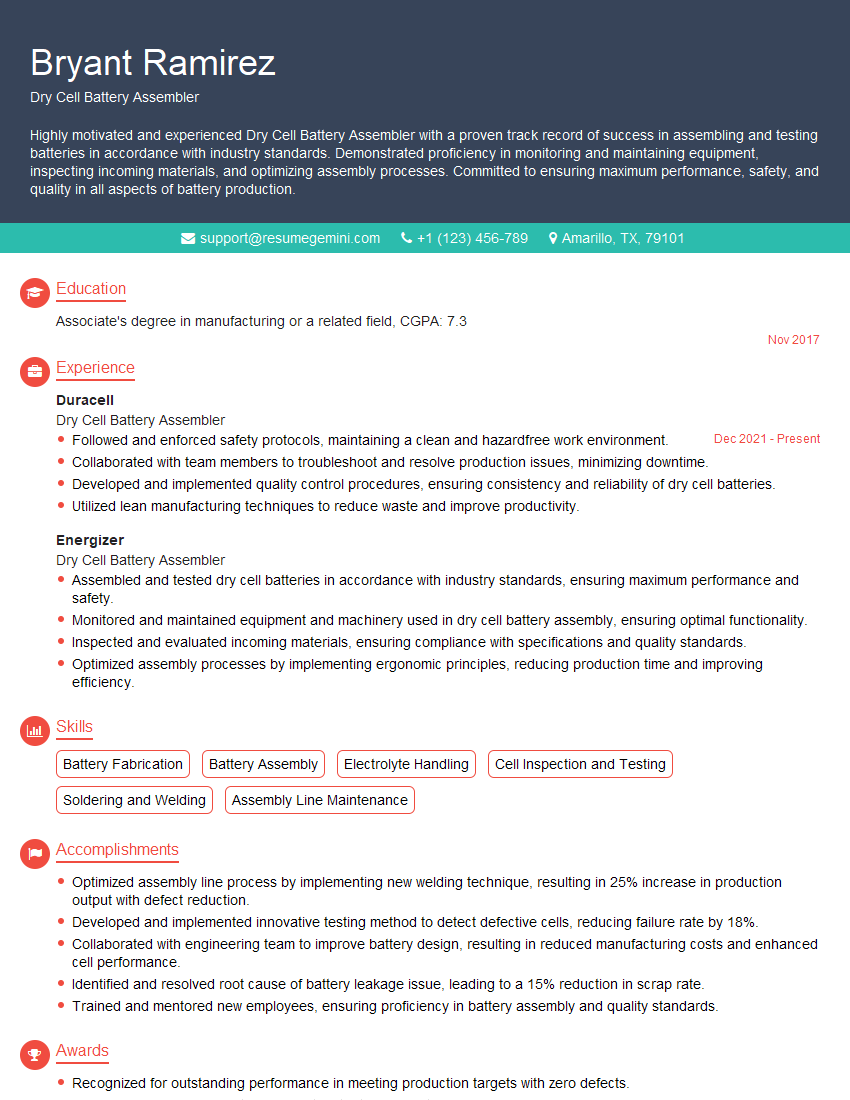

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Cell Battery Assembler

1. Explain the process of assembling a dry cell battery?

The process of assembling a dry cell battery involves several key steps:

- Mixing the active materials: The active materials, such as manganese dioxide and carbon, are mixed together to form a paste.

- Applying the paste to the anode: The paste is then applied to the anode, which is typically made of zinc.

- Inserting the cathode: The cathode, which is typically made of carbon, is inserted into the paste.

- Adding the electrolyte: The electrolyte, which is typically a solution of ammonium chloride, is added to the cell.

- Sealing the cell: The cell is then sealed to prevent the electrolyte from leaking out.

2. What are the different types of dry cell batteries?

Primary Batteries

- Alkaline batteries

- Carbon-zinc batteries

- Lithium batteries

Secondary Batteries

- Nickel-cadmium batteries

- Nickel-metal hydride batteries

- Lithium-ion batteries

3. What are the key safety precautions that must be followed when working with dry cell batteries?

When working with dry cell batteries, it is important to follow these safety precautions:

- Never short-circuit a battery.

- Never dispose of batteries in a fire.

- Keep batteries away from children.

- Always wear eye protection when working with batteries.

- Never attempt to recharge a non-rechargeable battery.

4. What are the most common problems that can occur with dry cell batteries?

The most common problems that can occur with dry cell batteries include:

- Leakage: Batteries can leak if they are damaged or if they are not stored properly.

- Corrosion: The terminals of batteries can corrode over time, which can make it difficult to make a connection.

- Loss of capacity: Batteries can lose their capacity to store energy over time.

- Failure: Batteries can fail completely if they are not used properly or if they are damaged.

5. How can you troubleshoot a dry cell battery that is not working?

To troubleshoot a dry cell battery that is not working, you can try the following steps:

- Check the terminals of the battery for corrosion. If the terminals are corroded, you can clean them with a vinegar-soaked cotton swab.

- Try replacing the battery with a new one. If the new battery works, then the old battery is likely dead.

- If the new battery does not work, then there may be a problem with the device that you are trying to power. You can try connecting the device to another power source to see if it works.

6. What are the environmental impacts of dry cell batteries?

Dry cell batteries can have a negative impact on the environment if they are not disposed of properly.

- Batteries can leach heavy metals into the soil and water, which can contaminate the environment.

- Batteries can also release toxic gases into the atmosphere, which can contribute to air pollution.

7. What are the latest advances in dry cell battery technology?

The latest advances in dry cell battery technology include:

- The development of new materials that can improve the performance of batteries.

- The development of new manufacturing processes that can make batteries more efficient and cost-effective.

- The development of new battery designs that can make batteries more compact and lightweight.

8. What are the future trends in dry cell battery technology?

The future trends in dry cell battery technology include:

- The increased use of renewable energy sources, such as solar and wind power, will lead to a greater demand for batteries that can store energy.

- The development of new electric vehicles will also lead to a greater demand for batteries that can power these vehicles.

- The continued development of new battery technologies will lead to the development of batteries that are more efficient, cost-effective, and environmentally friendly.

9. What are the key challenges in dry cell battery technology?

The key challenges in dry cell battery technology include:

- Improving the performance of batteries, such as increasing their capacity and power density.

- Reducing the cost of batteries, making them more affordable for consumers.

- Improving the safety of batteries, making them less likely to leak or explode.

10. What are the opportunities in dry cell battery technology?

The opportunities in dry cell battery technology include:

- The development of new materials and manufacturing processes that can improve the performance, cost, and safety of batteries.

- The development of new applications for batteries, such as in electric vehicles and renewable energy storage.

- The development of new business models for batteries, such as battery-as-a-service.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Cell Battery Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Cell Battery Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dry Cell Battery Assemblers are responsible for assembling dry cell batteries. These batteries are used in various devices, including flashlights, radios, and toys. To excel in this role, candidates should possess a meticulous nature, attention to detail, and the ability to follow instructions carefully.

1. Assembling Battery Components

Assemblers follow precise instructions to join battery components, ensuring correct polarity and alignment. They use specialized tools and equipment to connect terminals, insert electrolytes, and seal battery casings.

2. Quality Control Inspection

To guarantee battery performance, assemblers conduct thorough inspections throughout the assembly process. They check for defects, leaks, or any deviations from specifications. They also test battery voltage and capacity to meet quality standards.

3. Maintaining Work Area Safety

Assemblers prioritize safety measures while working with potentially hazardous materials. They adhere to safety protocols, wear appropriate protective gear, and maintain a clean and organized work area to prevent accidents.

4. Troubleshooting and Repair

Assemblers identify and resolve issues that may arise during the assembly process. They troubleshoot potential defects, repair faulty batteries, and ensure that all batteries meet performance requirements.

Interview Preparation Tips

To ace an interview for a Dry Cell Battery Assembler role, candidates should consider the following tips:

1. Understand the Role and Company

Research the job description and company website to gain a comprehensive understanding of the responsibilities, company culture, and industry trends. This knowledge will enable you to demonstrate your alignment with the position.

2. Highlight Relevant Skills and Experience

Emphasize your attention to detail, dexterity, and experience in assembly or manufacturing. If you have prior knowledge of battery assembly, mention specific techniques or equipment you are familiar with.

3. Show Enthusiasm and Eagerness to Learn

Express your interest in the battery industry and explain why you are eager to join the company. Demonstrate your willingness to learn new processes and contribute to the team’s success.

4. Prepare for Common Interview Questions

Anticipate questions related to your experience, skills, and understanding of battery assembly. Prepare thoughtful responses that showcase your capabilities and emphasize your dedication to quality and safety.

Example Outline for Answering Interview Questions

When answering interview questions, consider using a logical structure to present your responses clearly and effectively:

- Situation: Briefly describe the relevant situation or experience.

- Action: Explain the specific actions you took in that situation.

- Result: Quantify the outcome or impact of your actions, if possible.

By following these tips and preparing thoroughly, you can increase your chances of success in an interview for a Dry Cell Battery Assembler position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dry Cell Battery Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.