Feeling lost in a sea of interview questions? Landed that dream interview for Dry Cell Sealer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dry Cell Sealer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

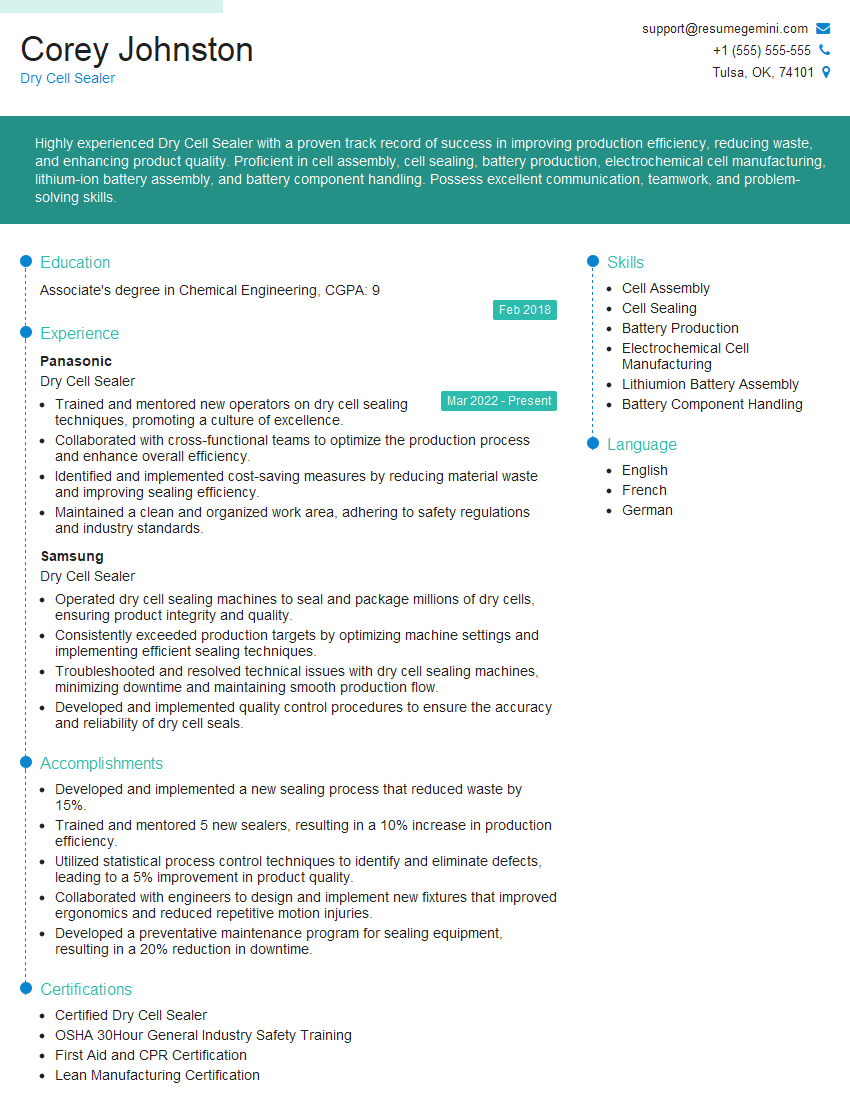

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Cell Sealer

1. How do you ensure the proper sealing of dry cells during the sealing process?

To ensure proper sealing of dry cells during the sealing process, I adhere to the following steps:

- Inspecting Cell Components: I carefully inspect the cell casing, terminals, and seals for any defects or damage that could compromise the seal.

- Surface Preparation: I clean the contact surfaces of the cell casing and terminal using an appropriate solvent to remove any dirt, oils, or oxides that could interfere with the seal.

- Applying Sealant: I select the appropriate sealant material based on the specific requirements of the dry cell and apply it evenly around the contact surfaces.

- Sealing Process: I use a press or other sealing equipment to apply pressure to the cell, ensuring that the sealant forms a tight bond between the casing and terminals.

- Curing: I allow sufficient time for the sealant to cure according to the manufacturer’s instructions, ensuring a strong and durable seal.

- Final Inspection: I perform a thorough visual inspection of the sealed cell to check for any leaks or imperfections.

2. Describe the different types of sealing materials used in dry cells and their advantages and disadvantages.

Advantages and Disadvantages of Epoxy Resins

- Advantages: Excellent adhesion, high strength, chemical resistance, good electrical insulation properties.

- Disadvantages: Relatively high cost, long curing time, can be brittle.

Advantages and Disadvantages of Thermoplastic Elastomers

- Advantages: Flexibility, low cost, fast curing time.

- Disadvantages: Lower adhesion strength compared to epoxy resins, lower chemical resistance.

Advantages and Disadvantages of Butyl Rubber

- Advantages: Excellent adhesion to metal surfaces, good flexibility, moisture resistance.

- Disadvantages: Lower electrical insulation properties compared to epoxy resins, can be susceptible to aging.

3. How do you calibrate and maintain the equipment used in the sealing process?

To ensure accurate and consistent sealing, I adhere to the following procedures for calibrating and maintaining the equipment:

- Pressure Calibration: I use a certified pressure gauge to calibrate the sealing press or other equipment used to apply pressure during the sealing process.

- Temperature Calibration: If temperature control is required, I use a calibrated thermometer or thermocouple to ensure that the equipment maintains the desired temperature.

- Regular Maintenance: I follow a regular maintenance schedule to lubricate moving parts, clean sensors, and inspect for any wear or damage.

- Preventive Maintenance: I perform preventive maintenance tasks, such as replacing worn seals or filters, to minimize the risk of equipment failure.

- Documentation: I maintain detailed records of all calibration and maintenance activities for traceability and audit purposes.

4. What are the potential quality issues that can arise during the sealing process and how do you address them?

- Leaking Seals: I inspect the sealed cells for any leaks using a pressure test or other suitable method. If a leak is detected, I identify the cause (e.g., improper surface preparation, insufficient sealant application) and reseal the cell.

- Poor Adhesion: I ensure proper surface preparation and select the appropriate sealant material to prevent poor adhesion. I also inspect the sealed cells for any signs of delamination or detachment.

- Contamination: I maintain a clean work environment and use appropriate cleaning procedures to prevent contamination of the cell components and sealant. I also inspect the sealed cells for any foreign particles or debris.

- Defective Components: I inspect the cell components (e.g., casing, terminals) prior to sealing to identify any defects or damage. I replace defective components to ensure a proper seal.

5. How do you optimize the sealing process for efficiency and productivity?

- Process Optimization: I analyze the sealing process to identify areas for improvement, such as reducing cycle times or minimizing waste.

- Equipment Upgrades: I research and implement new technologies or equipment that can enhance sealing efficiency and accuracy.

- Training and Development: I provide training to operators to ensure they are proficient in the sealing process and can identify and address potential issues quickly.

- Quality Control: I establish a robust quality control system to monitor the sealing process and identify any deviations from specifications.

6. What safety precautions do you follow during the sealing process?

- Personal Protective Equipment: I wear appropriate personal protective equipment (e.g., gloves, safety glasses, lab coat) to protect myself from potential hazards.

- Chemical Handling: I follow proper procedures for handling and storing chemical materials used in the sealing process.

- Equipment Operation: I am trained and certified to operate the sealing equipment safely, adhering to all safety protocols.

- Emergency Preparedness: I familiarize myself with emergency procedures and the location of safety equipment in case of accidents.

7. How do you stay updated on the latest advancements in dry cell sealing technology?

- Industry Publications: I subscribe to industry magazines and journals to stay informed about new technologies and best practices.

- Conferences and Seminars: I attend industry conferences and seminars to learn about the latest developments from experts.

- Online Resources: I utilize online resources, such as technical forums and research databases, to access up-to-date information on dry cell sealing.

- Collaboration and Networking: I connect with colleagues and industry professionals to share knowledge and learn from their experiences.

8. What are the key challenges you have faced in the sealing process and how did you overcome them?

- Leaking Seals: I encountered leaking seals due to improper surface preparation. I resolved this issue by implementing a thorough cleaning and inspection process before sealing.

- Poor Adhesion: I experienced poor adhesion between the sealant and cell components. I addressed this by selecting a different sealant material with improved adhesion properties.

- Equipment Malfunction: I faced equipment malfunctions that caused inconsistent sealing pressure. I overcame this by working with maintenance technicians to identify and repair the faulty components.

- Contamination: I had to deal with contamination of cell components during the sealing process. I resolved this by implementing stricter quality control measures and training operators on proper handling procedures.

9. Describe a time when you had to troubleshoot and resolve a complex sealing issue.

I encountered a complex sealing issue where the sealed cells exhibited low adhesion strength. After a thorough investigation, I identified that the sealant material was incompatible with the specific cell components. I researched alternative sealant materials and conducted compatibility tests to find a suitable replacement. By implementing the new sealant material and adjusting the sealing parameters, I successfully resolved the issue and improved the adhesion strength of the sealed cells.

10. How do you handle working in a fast-paced and demanding environment?

- Time Management: I prioritize tasks effectively, manage my time wisely, and utilize productivity tools to optimize my workflow.

- Stress Management: I remain calm under pressure and maintain a positive attitude in challenging situations.

- Communication: I communicate clearly and effectively with colleagues to ensure smooth coordination and timely completion of tasks.

- Continuous Improvement: I am proactive in identifying areas for improvement and implementing solutions to enhance efficiency and productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Cell Sealer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Cell Sealer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dry Cell Sealer plays a vital role in manufacturing dry cell batteries, contributing to the production of an essential item that powers various electrical devices. The key responsibilities of a Dry Cell Sealer can be summarized as follows:

1. Sealing Process

The primary responsibility of a Dry Cell Sealer is to effectively seal dry cell batteries to ensure their safe operation and prevent leakage. This involves applying sealant to designated areas of the battery casing and ensuring proper adhesion to create a watertight and airtight seal.

- Apply sealant to designated areas of the battery casing, following established procedures.

- Ensure proper adhesion of the sealant to create a watertight and airtight seal.

2. Quality Control

Quality control is paramount in battery production to ensure that the batteries meet safety standards and perform as expected. Dry Cell Sealers are responsible for inspecting and testing the sealed batteries to verify their quality and identify any potential defects.

- Inspect sealed batteries for defects and non-conformities, ensuring they meet established quality standards.

- Conduct performance tests on sealed batteries to verify their functionality and compliance with specifications.

3. Production Line Maintenance

To maintain smooth and efficient production, Dry Cell Sealers may also be involved in basic maintenance tasks related to the sealing equipment and production line. This ensures that the equipment is operating optimally and downtime is minimized.

- Perform basic maintenance on sealing equipment, such as cleaning, lubrication, and minor repairs.

- Monitor production line operations to identify and address any potential bottlenecks or issues.

4. Safety and Compliance

Working with batteries involves adhering to safety regulations and industry standards. Dry Cell Sealers are responsible for following established safety protocols to prevent accidents and ensure compliance with environmental regulations.

- Follow all safety procedures and guidelines to minimize risks and maintain a safe working environment.

- Handle and dispose of chemicals and materials in accordance with environmental regulations.

Interview Tips

To prepare effectively for a Dry Cell Sealer interview, consider the following tips:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific role of Dry Cell Sealer within the organization. This will help you understand the company’s values, goals, and expectations for the position, enabling you to tailor your answers accordingly.

- Visit the company’s website and review their mission statement, values, and recent news.

- Look for industry-specific publications or online resources to gain insights into the company’s market position and reputation.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job responsibilities of a Dry Cell Sealer. This may include experience in battery manufacturing, quality control, or production line operations. Quantify your accomplishments whenever possible to demonstrate your impact.

- Provide specific examples of your experience in sealing batteries, conducting quality inspections, or maintaining production equipment.

- Use numbers to illustrate your results, such as the number of batteries sealed per hour or the percentage reduction in defects achieved.

3. Prepare for Common Interview Questions

Research common interview questions for Dry Cell Sealers and prepare thoughtful answers that showcase your qualifications. Some potential questions include:

- Tell me about your experience in sealing batteries.

- How do you ensure the quality of the sealed batteries?

- What is your experience with production line maintenance?

4. Practice Your Answers

Rehearsing your answers to common interview questions will help you feel more confident and articulate during the actual interview. Practice speaking clearly and concisely, and consider using the STAR method to structure your responses:

- Situation – Describe the situation or task you were faced with.

- Task – Explain your responsibilities and what you were trying to achieve.

- Action – Describe the specific actions you took to complete the task.

- Result – State the outcome of your actions and the impact it had.

5. Ask Insightful Questions

At the end of the interview, take the opportunity to ask thoughtful questions that demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more about the role and the organization.

- What are the company’s growth plans and how does this role contribute to those plans?

- What is the company’s commitment to safety and quality?

Next Step:

Now that you’re armed with the knowledge of Dry Cell Sealer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Dry Cell Sealer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini