Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dry Cell Tester interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dry Cell Tester so you can tailor your answers to impress potential employers.

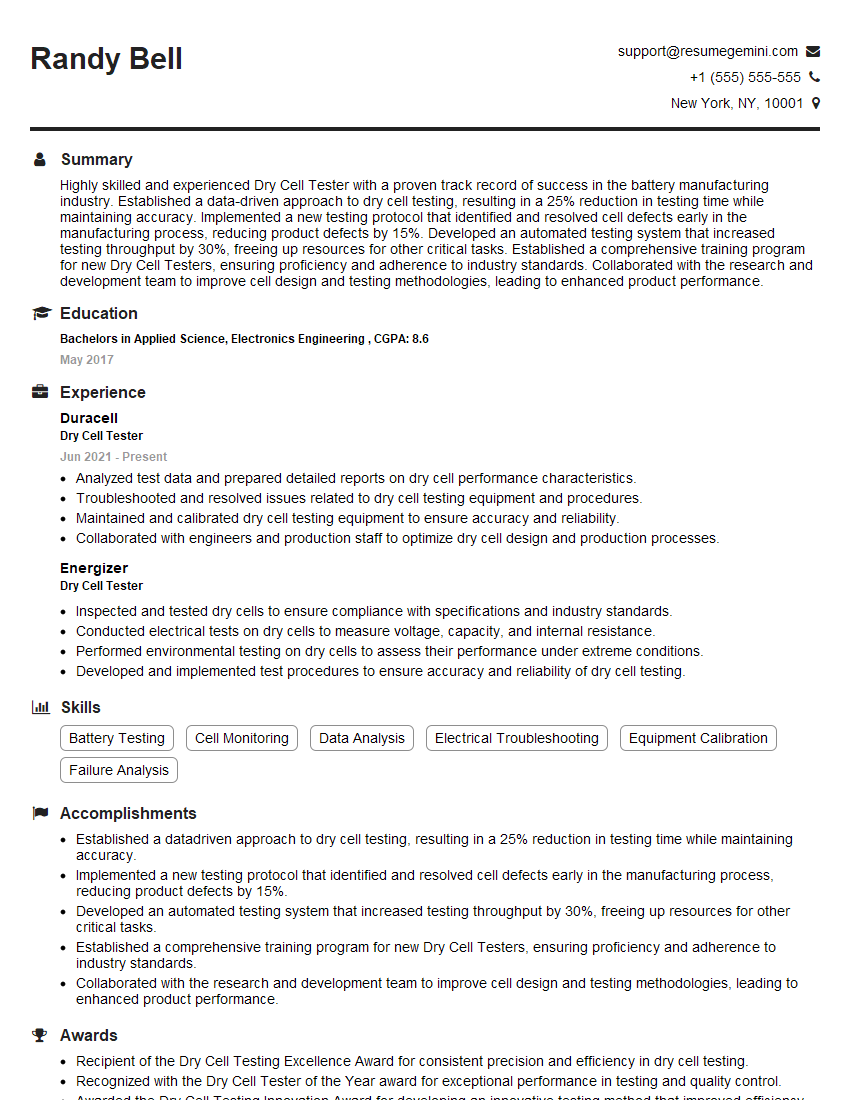

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Cell Tester

1. Explain the process of testing dry cells?

The process of testing dry cells involves several steps to evaluate their performance and ensure they meet the required specifications:

- Visual Inspection: Examine the cell for any physical damage, leaks, or corrosion.

- Voltage Measurement: Measure the open-circuit voltage of the cell using a voltmeter to determine its initial voltage capacity.

- Load Test: Connect the cell to a known load (e.g., resistor) and measure the voltage drop to evaluate its ability to deliver current under load.

- Capacity Test: Discharge the cell at a constant current rate until its voltage reaches a predefined cutoff point, determining its total capacity.

- Shelf-Life Test: Store the cell under controlled conditions for an extended period and periodically measure its voltage to assess its stability over time.

- Data Analysis: Record and analyze the test results to evaluate the cell’s performance against specifications, identify any deviations, and make necessary adjustments.

2. What are the different types of dry cells?

- Alkaline Dry Cells: Provide high energy density and long shelf life, used in devices requiring continuous power (e.g., toys, flashlights).

- Zinc-Carbon Dry Cells: Inexpensive and suitable for low-drain applications (e.g., remote controls, clocks).

- Lithium Dry Cells: Compact and lightweight with high energy density and long shelf life, used in electronic devices (e.g., cameras, laptops).

- Mercury Dry Cells: No longer commonly used due to environmental concerns, but provide stable voltage and high current capabilities.

- Silver-Oxide Dry Cells: Used in devices requiring high and constant voltage (e.g., watches, hearing aids).

3. What are the safety precautions to consider when testing dry cells?

Safety precautions are crucial when testing dry cells to prevent potential hazards:

- Wear Protective Gear: Use gloves, safety glasses, and a lab coat to protect against chemical spills or explosions.

- Proper Ventilation: Ensure adequate ventilation in the testing area to prevent the buildup of toxic fumes.

- Avoid Short Circuits: Prevent accidental short circuits by using insulated tools and handling cells with care.

- Dispose Properly: Discard used cells properly according to local regulations to avoid environmental contamination.

- Follow Manufacturer Instructions: Adhere to the manufacturer’s guidelines for handling and testing dry cells to ensure safety.

4. How do you calibrate the equipment used in dry cell testing?

Calibration of equipment ensures accurate and reliable test results:

- Voltmeter: Use a reference voltage source to calibrate the voltmeter to ensure accurate voltage measurements.

- Load Resistor: Measure the resistance of the load resistor using a precision ohmmeter to verify its value.

- Discharge Device: Calibrate the discharge device by comparing its output current to a known reference current source.

- Environmental Chamber: Calibrate the temperature and humidity sensors within the environmental chamber to ensure accurate readings.

- Follow Manufacturer Guidelines: Refer to the manufacturer’s instructions for specific calibration procedures and intervals.

5. What are the common defects found in dry cells?

- Leakage: Corrosion or damage to the cell casing, resulting in electrolyte leakage.

- Low Capacity: Reduced energy storage capability due to depletion of active materials.

- High Internal Resistance: Increased resistance within the cell, impacting current delivery.

- Voltage Instability: Fluctuations in cell voltage during discharge, affecting device performance.

- Short Circuit: Internal connection between positive and negative terminals, leading to cell failure.

6. How do you determine the shelf life of a dry cell?

Shelf-life determination involves evaluating the cell’s performance over time:

- Open-Circuit Voltage: Monitor the cell’s voltage periodically under open-circuit conditions to assess its voltage retention.

- Capacity Test: Conduct capacity tests at regular intervals to measure the cell’s ability to deliver current over time.

- Environmental Conditions: Consider the temperature and humidity conditions during storage, as they impact cell degradation.

- Data Analysis: Analyze the test results to determine the rate of capacity loss and predict the estimated shelf life.

- Manufacturer Specifications: Refer to the manufacturer’s datasheet for the expected shelf life of the specific cell type.

7. What are the different methods used to test the capacity of dry cells?

- Constant Current Discharge: Discharge the cell at a constant current until the voltage reaches a predefined cutoff point.

- Pulsed Discharge: Apply a series of pulses to the cell and measure the voltage response to determine its capacity.

- Intermittent Discharge: Discharge the cell for a specific duration, followed by a rest period, and repeat the cycle to assess its ability to deliver current over extended periods.

- Load Profile Testing: Simulate the actual load profile of a specific device to evaluate the cell’s performance under varying current demands.

- Temperature Testing: Test the cell’s capacity at different temperatures to assess its performance in various operating conditions.

8. How do you evaluate the environmental impact of dry cells?

Environmental impact assessment considers the potential effects of dry cells on the environment:

- Material Composition: Analyze the materials used in the cell, including metals, plastics, and chemicals, to identify any hazardous substances.

- Manufacturing Process: Evaluate the environmental impact of the manufacturing process, such as energy consumption, wastewater generation, and air emissions.

- End-of-Life Management: Assess the disposal options for dry cells, including recycling, landfill disposal, and potential contamination risks.

- Regulations: Comply with environmental regulations and industry standards to minimize the environmental footprint of dry cells.

- Sustainability Initiatives: Promote the use of eco-friendly materials, sustainable manufacturing practices, and responsible end-of-life management.

9. What are the emerging trends and advancements in dry cell technology?

- High-Capacity Cells: Development of cells with increased energy storage capacity for extended device usage.

- Fast-Charging Cells: Advances in electrode materials and cell design enable faster charging times.

- Long-Life Cells: Research focuses on improving cell longevity and reducing capacity loss over time.

- Flexible Cells: Development of flexible and bendable cells for integration into wearable devices and unique applications.

- Sustainable Materials: Emphasis on using environmentally friendly materials and reducing the carbon footprint of cell production.

10. How do you stay updated with the latest developments in dry cell testing?

- Industry Publications: Read technical journals, attend conferences, and participate in webinars to stay informed about advancements in testing methodologies.

- Professional Development: Pursue certifications and training programs related to dry cell testing to enhance knowledge and skills.

- Collaboration: Network with industry experts, attend workshops, and engage in discussions to share and acquire new insights.

- Manufacturers’ Resources: Utilize technical documentation, application notes, and online forums provided by cell manufacturers.

- Research and Innovation: Actively participate in research projects and explore emerging technologies to contribute to the field of dry cell testing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Cell Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Cell Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dry Cell Testers are accountable for conducting tests on dry cell batteries to assess their performance, reliability, and safety. Their responsibilities encompass:

1. Battery Testing

Conducting a wide range of tests on dry cell batteries, including capacity, voltage, leakage, and internal resistance measurements. Utilizing various testing equipment and following established testing procedures to ensure accurate and reliable results.

- Performing capacity tests to determine the battery’s ability to deliver a specific amount of current over a specified period.

- Measuring voltage levels under different load conditions to assess battery performance and identify potential issues.

2. Data Analysis and Reporting

Analyzing test data and interpreting results to identify trends, anomalies, and potential areas for improvement. Preparing detailed reports summarizing test findings and making recommendations for battery design, manufacturing, or quality control.

- Evaluating test results against established specifications and industry standards to ensure compliance.

- Identifying and documenting any deviations or defects observed during testing, along with potential causes and corrective actions.

3. Quality Control

Monitoring and maintaining the quality of dry cell batteries throughout the production process. Participating in quality assurance programs and implementing corrective actions to address any identified issues or non-conformances.

- Inspecting incoming raw materials and finished products to verify compliance with specifications.

- Collaborating with production teams to identify and resolve manufacturing defects or process inefficiencies that impact battery quality.

4. Research and Development

Supporting research and development efforts related to dry cell battery technology. Evaluating new materials, designs, and manufacturing techniques to improve battery performance and efficiency. Conducting experiments and testing prototypes to validate new concepts and designs.

- Collaborating with engineers and scientists to develop and implement innovative battery solutions.

- Staying abreast of industry trends and advancements in dry cell battery technology.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips to help you ace your interview for a Dry Cell Tester position:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific Dry Cell Tester position. This will give you a good understanding of their business, industry, and the role you’ll be expected to play. You can find information on the company website, LinkedIn, and other online sources.

- Review the company’s mission, values, and products/services.

- Identify the key responsibilities and qualifications for the Dry Cell Tester position.

2. Practice Your Answers

Once you have a good understanding of the company and position, you can start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview. Some questions you may want to practice include:

- Tell me about your experience in dry cell battery testing.

- What are the different types of tests you have performed on dry cell batteries?

- How do you analyze and interpret test data?

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the Dry Cell Tester position. This includes your technical skills, such as your knowledge of battery testing equipment and procedures, as well as your soft skills, such as your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible, using specific examples to demonstrate your impact.

- Be prepared to discuss your experience in a way that shows how it aligns with the job requirements.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the company and the position. This shows that you’re interested in the opportunity and that you’re taking the interview seriously. Some questions you may want to ask include:

- What are the company’s goals for the Dry Cell Tester position?

- What are the biggest challenges facing the Dry Cell Tester team?

- What opportunities are there for professional development and growth within the company?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Dry Cell Tester, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Dry Cell Tester positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.