Are you gearing up for an interview for a Dry Charge Process Attendant position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Dry Charge Process Attendant and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

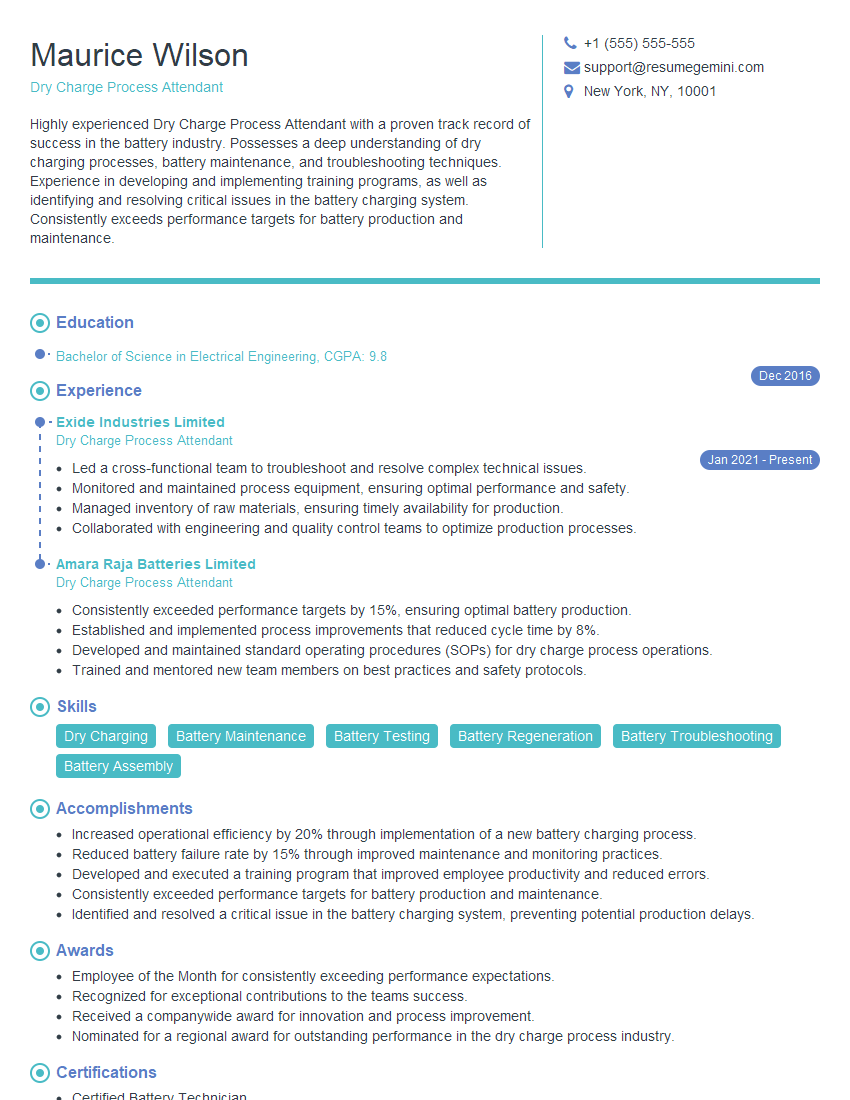

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Charge Process Attendant

1. Explain the process of dry charge in a battery?

During the dry charge process, the negative plate of the battery is charged positively, while the positive plate is charged negatively. This is done by passing an electric current through the battery in a controlled manner. The charging process is continued until the desired level of charge is reached. Once the charging process is complete, the battery is disconnected from the power source and allowed to rest for a period of time.

2. What are the key parameters to monitor during the dry charge process?

Temperature

- The temperature of the battery must be closely monitored during the dry charge process to ensure that it does not exceed the specified limits.

- Excessive temperatures can damage the battery and reduce its lifespan.

Current

- The current flowing through the battery must also be monitored to ensure that it does not exceed the specified limits.

- Excessive current can damage the battery and reduce its lifespan.

Voltage

- The voltage across the battery must be monitored to ensure that it reaches the desired level of charge.

- Insufficient voltage will result in an incomplete charge, while excessive voltage can damage the battery.

3. What are the safety precautions that must be taken when handling dry charged batteries?

- Dry charged batteries must be handled with care to avoid damage.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Do not short-circuit the battery terminals.

- Do not charge the battery beyond the specified voltage and current limits.

- Do not expose the battery to excessive heat or cold.

4. What is the purpose of the formation charge in the dry charge process?

- The formation charge is a critical step in the dry charge process that helps to form the active materials on the battery plates.

- This process involves charging the battery at a low current for an extended period of time.

- The formation charge helps to improve the battery’s performance and lifespan.

5. How do you troubleshoot a dry charged battery that is not charging properly?

- Check the battery connections to ensure that they are clean and tight.

- Check the battery charger to ensure that it is functioning properly.

- Check the battery voltage to ensure that it is within the specified limits.

- If the battery voltage is low, try charging the battery for a longer period of time.

- If the battery voltage is high, stop charging the battery and contact a qualified technician.

6. What are the advantages of using dry charged batteries?

- Dry charged batteries have a longer shelf life than wet charged batteries.

- Dry charged batteries are less likely to leak or spill.

- Dry charged batteries can be stored in a wider range of temperatures than wet charged batteries.

- Dry charged batteries are more resistant to vibration and shock than wet charged batteries.

7. What are the disadvantages of using dry charged batteries?

- Dry charged batteries require a longer charging time than wet charged batteries.

- Dry charged batteries are more expensive than wet charged batteries.

- Dry charged batteries can be damaged if they are not handled properly.

8. What are the applications of dry charged batteries?

- Dry charged batteries are used in a wide variety of applications, including:

- Automotive

- Marine

- Industrial

- Renewable energy

- Backup power

9. What is the future of dry charged batteries?

- Dry charged batteries are expected to continue to grow in popularity in the coming years.

- This growth is being driven by the increasing demand for batteries in electric vehicles and renewable energy applications.

- Dry charged batteries offer a number of advantages over wet charged batteries, including longer shelf life, less maintenance, and better performance.

10. What are the key challenges facing the dry charge battery industry?

- The dry charge battery industry is facing a number of challenges, including:

- The high cost of raw materials

- The need for improved performance

- The need for longer cycle life

- The need for faster charging times

11. How do you stay up-to-date on the latest developments in the dry charge battery industry?

- I stay up-to-date on the latest developments in the dry charge battery industry by reading trade publications, attending industry events, and networking with other professionals in the field.

- I am also involved in several research projects that are focused on developing new and improved dry charge battery technologies.

12. What are your career goals?

- My career goal is to become a leading expert in the dry charge battery industry.

- I am passionate about developing new and improved battery technologies that can help to meet the world’s growing energy needs.

- I believe that dry charge batteries have the potential to revolutionize the way we power our lives, and I am excited to be a part of this exciting industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Charge Process Attendant.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Charge Process Attendant‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dry Charge Process Attendant is responsible for various tasks in the production of dry charge batteries. These tasks include:

1. Preparation and Mixing

Following established procedures, they prepare and mix raw materials, including lead oxides, water, and additives, to create the active material for the battery plates.

2. Paste Application

Using specialized equipment, they apply the prepared paste onto lead grids to form the battery plates. They ensure proper plate thickness and uniformity to meet quality standards.

3. Drying and Curing

They oversee the drying and curing process of the battery plates. They control temperature and humidity to achieve optimal performance and prevent defects.

4. Plate Assembly

They assemble the cured plates into battery cells, connecting them electrically and ensuring proper polarity. They adhere to specified assembly sequences and torque requirements.

5. Maintenance and Troubleshooting

They perform regular maintenance on equipment, including mixers, paste applicators, and curing ovens. They troubleshoot any issues and take corrective actions to minimize downtime.

6. Quality Control

They conduct quality checks throughout the process, inspecting raw materials, plates, and assembled cells. They identify and rectify any deviations from specifications to ensure product quality.

7. Material Handling

They safely handle and transport raw materials, plates, and finished batteries. They comply with established procedures to prevent accidents and maintain a clean and organized work environment.

Interview Tips

To ace an interview for a Dry Charge Process Attendant position, candidates should prepare thoroughly and demonstrate their knowledge and skills. Here are some tips:

1. Research the Company and Industry

Gain an understanding of the company’s background, products, and industry trends. Research the specific role and its responsibilities to tailor your answers accordingly.

2. Highlight Relevant Experience and Skills

Emphasize your experience in dry charge battery production or related manufacturing processes. Showcase your knowledge of raw materials, paste application techniques, and quality control measures.

3. Explain Your Understanding of the Process

Demonstrate your understanding of the dry charge process, including preparation, mixing, drying, curing, plate assembly, and quality control. Explain how each step contributes to the final product.

4. Showcase Your Attention to Detail

Highlight your meticulous nature and attention to detail. Emphasize your ability to follow procedures precisely, inspect materials for defects, and ensure product quality.

5. Prepare for Technical Questions

Expect technical questions related to the dry charge process. Be prepared to discuss topics such as lead oxide composition, paste viscosity, and curing temperatures.

6. Ask Thoughtful Questions

Asking thoughtful questions shows your engagement and interest in the position. Prepare questions about the company’s goals, the production process, or the opportunities for professional development.

7. Be Enthusiastic and Positive

Demonstrate your enthusiasm for the role and your eagerness to contribute to the team. Show a positive attitude and a willingness to learn and grow.

8. Practice and Mock Interviews

Conduct practice interviews with a friend or mentor to familiarize yourself with common questions and to improve your delivery. This will help you feel more confident and prepared during the actual interview.

9. Dress Professionally and Be Punctual

Make a good first impression by dressing professionally and arriving on time for the interview. These simple steps show respect for the interviewer and the company.

10. Follow Up

After the interview, send a thank-you note to the interviewer. Express your appreciation for their time and reiterate your interest in the position.

Next Step:

Now that you’re armed with the knowledge of Dry Charge Process Attendant interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Dry Charge Process Attendant positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini