Are you gearing up for a career in Dry Food Products Mixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dry Food Products Mixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

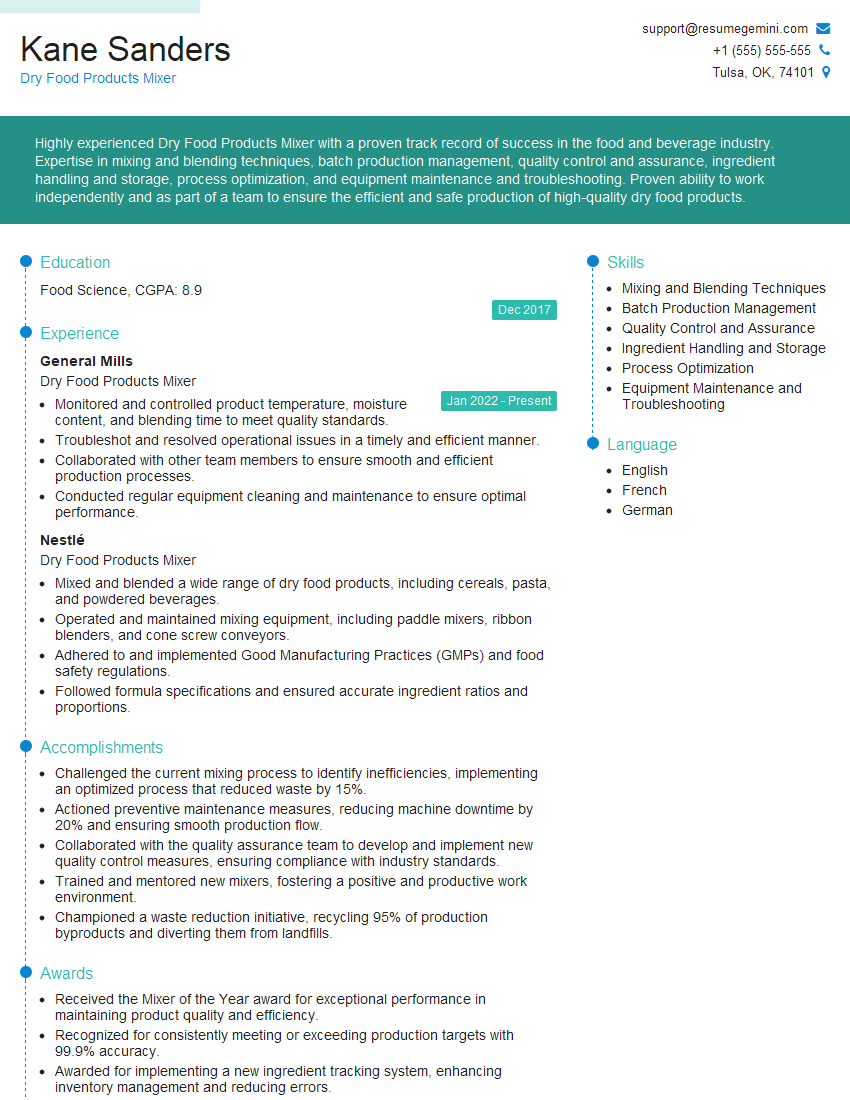

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Food Products Mixer

1. What are the different types of dry food products mixers, and what are their advantages and disadvantages?

There are various types of dry food products mixers, each with its own advantages and disadvantages. Here’s a brief overview of some common types:

- Ribbon blender: Used for gentle and consistent blending of dry ingredients. Advantages include low shear force and low maintenance requirements. Disadvantage is that it can be slow for large batches.

- Paddle blender: Suitable for moderate to high shear mixing of dry ingredients. Advantages include high mixing efficiency and ability to handle a wide range of materials. Disadvantage is that it can generate more noise and heat.

- V-blender: Ideal for blending dry ingredients with different densities and particle sizes. Advantages include efficient mixing and low shear force. Disadvantage is that it requires more space and can be less suitable for delicate materials.

- Double cone blender: Used for thorough and homogeneous mixing of dry ingredients. Advantages include high mixing efficiency and low maintenance requirements. Disadvantage is that it can be more expensive than other types of mixers.

2. How do you determine the correct mixer size and type for a specific dry food product?

Factors to consider when choosing a mixer:

- Batch size: Volume of dry ingredients to be mixed in each batch.

- Material properties: Density, particle size, and flowability of the dry ingredients.

- Mixing requirements: Level of mixing efficiency and homogeneity required.

- Space constraints: Dimensions of the available area for the mixer.

Steps for selecting the correct mixer:

- Calculate the batch volume based on the product density and desired batch size.

- Determine the required mixing intensity and mixing time based on the material properties and mixing requirements.

- Choose the mixer type that matches the required mixing intensity and can handle the batch volume.

- Consider the space constraints and select the mixer size that fits the available area.

3. What are the key design features to consider when selecting a dry food products mixer?

- Mixing chamber design: Shape, size, and materials of the mixing chamber.

- Mixing mechanism: Type and configuration of the mixing blades or paddles.

- Discharge system: Method used to discharge the mixed product.

- Materials of construction: Compatibility with the dry food products and any regulatory requirements.

- Sanitary features: Ease of cleaning and meeting sanitary standards.

4. How do you ensure the quality of the mixing process, and how do you troubleshoot any potential issues?

- Process validation: Establish optimal mixing parameters through experimentation and testing.

- In-process monitoring: Use sensors or visual inspection to track mixing progress and identify any deviations.

- Quality control: Conduct regular checks on the mixed product to ensure consistent quality.

- Troubleshooting: Identify potential issues such as uneven mixing, product degradation, or equipment malfunction, and implement corrective actions.

5. What are the maintenance and safety procedures for dry food products mixers?

Maintenance procedures:

- Regular cleaning and sanitation to prevent contamination and maintain sanitary conditions.

- Periodic inspection and lubrication of moving parts to ensure smooth operation and prevent wear.

- Checking and replacing worn or damaged components to maintain optimal performance.

Safety procedures:

- Lock-out/tag-out procedures during maintenance and cleaning to prevent accidental startup.

- Proper use of personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Training and supervision of operators to ensure safe and efficient operation.

6. What are the latest advancements in dry food products mixer technology, and how do they improve the mixing process?

- High-shear mixers: Employ high-speed impellers to create intense mixing for challenging materials.

- Continuous mixers: Provide continuous operation for high-volume applications.

- Automated control systems: Allow for precise control of mixing parameters and monitoring of mixing progress.

- Sanitary design features: Enhanced designs to improve cleanability and reduce the risk of contamination.

- Energy-efficient mixers: Utilize innovative designs and materials to reduce energy consumption.

7. How do you stay up-to-date with the latest industry best practices and advancements in dry food products mixing?

- Attend industry conferences and exhibitions: Network with experts and learn about new technologies.

- Read technical journals and publications: Stay informed about research and development in the field.

- Participate in online forums and communities: Engage with peers and share knowledge.

- Seek training and certifications: Enhance skills and demonstrate proficiency in industry standards.

8. What are the challenges and opportunities in the dry food products mixing industry?

Challenges:

- Meeting increasing demand: Growing population and changing dietary habits drive the need for efficient mixing solutions.

- Handling diverse materials: Mixers must accommodate a wide range of dry food products with varying properties.

- Ensuring product quality: Maintaining consistent mixing performance and preventing contamination is crucial.

Opportunities:

- Innovation in mixer design: Developing new technologies to improve mixing efficiency and reduce costs.

- Sustainability: Designing energy-efficient mixers and implementing eco-friendly practices.

- Expansion into new markets: Exploring opportunities in emerging industries and international markets.

9. How do you see the future of dry food products mixing evolving?

- Automation and AI: Increased use of automated systems and artificial intelligence to optimize mixing processes.

- Customization and personalization: Development of mixers tailored to specific product requirements and consumer preferences.

- Sustainability and transparency: Emphasis on eco-friendly designs and traceability throughout the mixing process.

10. Do you have any questions for me about the role or the company?

This is an opportunity for you to ask questions about the job responsibilities, the company culture, or any other aspects of the position that you are interested in.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Food Products Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Food Products Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Dry Food Products Mixer is responsible for overseeing the mixing and blending of dry food products. They ensure that all products meet the required specifications and quality standards. The key responsibilities of a Dry Food Products Mixer include:1. Operating and maintaining mixing equipment

Setting up and operating mixing equipment to blend dry food ingredients.

- Monitoring the mixing process to ensure that the desired blend is achieved.

- Cleaning and maintaining mixing equipment to ensure optimal performance.

2. Preparing dry food ingredients

Measuring and weighing dry food ingredients according to specified recipes.

- Checking the quality of ingredients and ensuring they meet specifications.

- Preparing ingredients for mixing, such as grinding or sifting.

3. Ensuring product quality

Conducting quality checks on mixed products to ensure they meet specifications.

- Taking samples of products for testing and analysis.

- Identifying and resolving any quality issues that arise during the mixing process.

4. Maintaining a clean and organized work area

Keeping the mixing area clean and organized to prevent contamination.

- Following all safety regulations and procedures.

- Maintaining a positive and productive work environment.

Interview Tips

To ace an interview for a Dry Food Products Mixer position, it is important to:1. Research the company and the position

Research the company’s website, social media pages, and industry news to learn more about their products, culture, and values.

- Identify the specific skills and experience that the company is looking for in a Dry Food Products Mixer.

- Tailor your resume and cover letter to highlight your relevant skills and experience.

2. Practice answering common interview questions

Prepare answers to common interview questions, such as:

- “Tell me about your experience in mixing dry food products.”

- “How do you ensure that your products meet quality standards?”

- “What are your strengths and weaknesses as a Dry Food Products Mixer?”

3. Be prepared to talk about your experience with mixing equipment

Describe your experience with different types of mixing equipment.

- Explain how you troubleshoot and solve problems that may arise during the mixing process.

- Discuss any certifications or training you have related to mixing equipment.

4. Emphasize your commitment to safety and quality

Highlight your commitment to safety by describing your experience with following safety regulations and procedures.

- Explain how you maintain a clean and organized work area to prevent contamination.

- Describe your experience with conducting quality checks on mixed products.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dry Food Products Mixer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.