Are you gearing up for a career in Dry Goods Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dry Goods Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

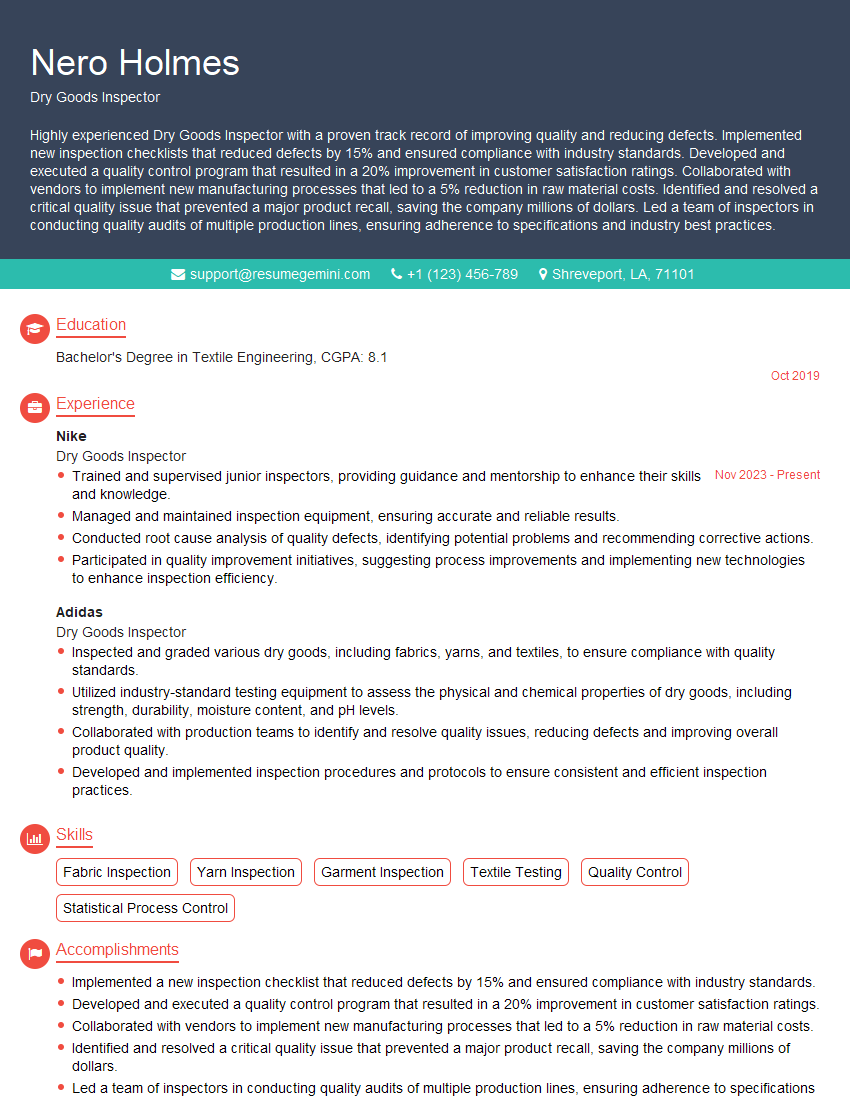

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Goods Inspector

1. What are the key responsibilities of a Dry Goods Inspector?

As a Dry Goods Inspector, my primary responsibilities would include:

- Inspecting and evaluating dry goods to ensure compliance with established specifications and quality standards

- Examining fabrics, textiles, yarns, and other materials for defects, damage, and conformity to design

- Conducting physical and chemical tests to assess product quality and performance

- Identifying and reporting any deviations, irregularities, or concerns to management for further action

- Maintaining accurate inspection records and documentation

2. Describe the different types of inspection methods used for dry goods.

Visual Inspection

- Examining goods for physical defects, damage, or discrepancies in color, texture, or appearance

- Using tools such as magnifying glasses, light boxes, or measuring devices for detailed inspection

Performance Inspection

- Testing goods to evaluate their functionality, durability, or other performance criteria

- Conducting tests such as tensile strength testing, colorfastness tests, or flammability tests

Dimensional Inspection

- Verifying the dimensions, shape, and size of goods against specified standards

- Using measuring tools such as rulers, calipers, or gauges for precise measurements

3. How do you handle discrepancies or defects identified during inspection?

When I identify discrepancies or defects, I follow a systematic process to ensure timely and appropriate action:

- Document the nature and severity of the discrepancy or defect

- Isolate and quarantine affected goods to prevent further distribution

- Inform management and relevant stakeholders of the issue

- Work with suppliers or manufacturers to determine the cause and resolve the problem

- Record and track corrective actions taken to prevent future occurrences

4. What are some common defects you have encountered in dry goods?

Some common defects I have encountered in dry goods include:

- Fabric defects: holes, tears, stains, uneven weave, color variations

- Yarns defects: knots, slubs, uneven tension, incorrect yarn count

- Textile defects: pilling, shrinkage, fading, dimensional non-conformities

- Manufacturing defects: incorrect labelling, missing accessories, damaged packaging

5. How do you prioritize the inspection of goods based on their importance and urgency?

I prioritize the inspection of goods based on the following factors:

- Importance: Critical products or materials that impact safety or customer satisfaction are inspected first.

- Urgency: Goods with tight deadlines or those needed for immediate production are prioritized.

- Risk: Goods with a higher risk of defects or damage due to their material, design, or intended use are inspected more thoroughly.

- Cost: The potential financial impact of accepting defective goods influences the level of inspection required.

6. What are the quality standards and specifications that apply to dry goods inspection?

I am familiar with various quality standards and specifications that apply to dry goods inspection, including:

- American Society for Testing and Materials (ASTM) standards for textiles and fabrics

- International Organization for Standardization (ISO) standards for quality management and inspection

- Government regulations and industry-specific standards for safety and performance

- Customer-specific requirements and specifications for specific products or applications

7. How do you stay updated on the latest inspection techniques and industry best practices?

I make a conscious effort to stay up-to-date on the latest inspection techniques and industry best practices through the following:

- Attending industry conferences and workshops

- Reading technical articles and publications

- Networking with other professionals in the field

- Participating in training programs and certifications

8. What tools and equipment do you use for dry goods inspection?

I am proficient in using a variety of tools and equipment for dry goods inspection, including:

- Magnifying glasses for detailed examination

- Light boxes to assess color and texture

- Micrometers and calipers for precise measurements

- Tensile strength testing machines for fabric strength evaluation

- Colorfastness testing equipment to assess color durability

9. How do you ensure the accuracy and reliability of your inspections?

To ensure the accuracy and reliability of my inspections, I adhere to the following principles:

- Calibration: Regularly calibrate all inspection equipment and tools to maintain their accuracy.

- Consistency: Follow standardized inspection procedures and criteria to minimize variability in results.

- Objectivity: Conduct inspections without bias or external influences.

- Records: Maintain detailed records of all inspections, including any discrepancies or defects identified.

- Continuous Improvement: Regularly review and improve inspection processes to enhance accuracy and efficiency.

10. How do you manage the workload and prioritize tasks when multiple orders or shipments arrive for inspection?

When managing a heavy workload, I prioritize tasks and allocate resources effectively through the following strategies:

- Planning: Plan the inspection schedule based on order urgency, product importance, and available resources.

- Delegation: Delegate tasks to qualified team members, providing clear instructions and training when necessary.

- Communication: Communicate with management and stakeholders to manage expectations and coordinate priorities.

- Continuous Monitoring: Monitor the progress of inspections and make necessary adjustments to the schedule to ensure timely completion.

- Technology: Utilize inspection management software or systems to streamline workflow and track progress.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Goods Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Goods Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dry Goods Inspector is a professional responsible for inspecting various types of dry goods and ensuring they meet established quality standards. Key job responsibilities typically include:

1. Inspecting Dry Goods Quality

Inspecting incoming shipments of dry goods, such as fabrics, yarns, and textiles, to verify conformity with specifications, quality standards, and customer requirements.

- Visually inspecting goods for defects, such as stains, tears, color inconsistencies, or incorrect labeling.

- Using measuring instruments, such as calipers or micrometers, to verify dimensions, weight, and other physical attributes.

2. Evaluating Production Processes

Observing and evaluating production processes to identify potential quality issues and recommend improvements.

- Monitoring production lines to ensure adherence to established standards and procedures.

- Analyzing production data and identifying trends that may indicate potential problems.

3. Maintaining Quality Control Records

Maintaining accurate and detailed records of inspections and quality control tests, including any identified defects or nonconformances.

- Documenting inspection results, including the date, type of goods inspected, and any observations or defects found.

- Storing and managing quality control records in a systematic and organized manner.

4. Troubleshooting and Resolving Quality Issues

Identifying and troubleshooting quality issues, and working with relevant personnel to resolve them promptly and effectively.

- Investigating the root causes of quality defects and recommending corrective actions.

- Collaborating with production teams, suppliers, and other stakeholders to implement solutions and improve quality.

Interview Tips

To prepare for a Dry Goods Inspector interview, it’s essential to:

1. Research the Company and Industry

Thoroughly research the company you’re applying to and the dry goods industry. This will help you understand their business operations, quality standards, and industry trends.

- Visit the company’s website to learn about their products, services, and mission.

- Read industry publications and attend relevant events to stay informed about best practices and emerging technologies.

2. Practice Your Technical Skills

Demonstrate your proficiency in inspection techniques, quality control methods, and relevant software tools. You can do this by:

- Preparing examples of your previous inspection reports and quality control projects.

- Practicing using inspection equipment, such as calipers or microscopes.

3. Highlight Your Communication and Problem-Solving Abilities

Emphasize your strong communication skills and ability to work effectively with others. You can provide examples of situations where you successfully communicated inspection results, resolved quality issues, or collaborated with teams.

- Share examples of how you effectively communicated inspection findings to stakeholders, including both technical and non-technical audiences.

- Describe a situation where you identified and resolved a quality issue, demonstrating your problem-solving and analytical skills.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare your answers to highlight your relevant skills and experience. Some questions you might encounter include:

- Tell me about your experience in dry goods inspection.

- Describe a quality control issue you faced and how you resolved it.

- How do you stay updated on industry best practices for dry goods inspection?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dry Goods Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.