Feeling lost in a sea of interview questions? Landed that dream interview for Dry Kiln Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dry Kiln Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

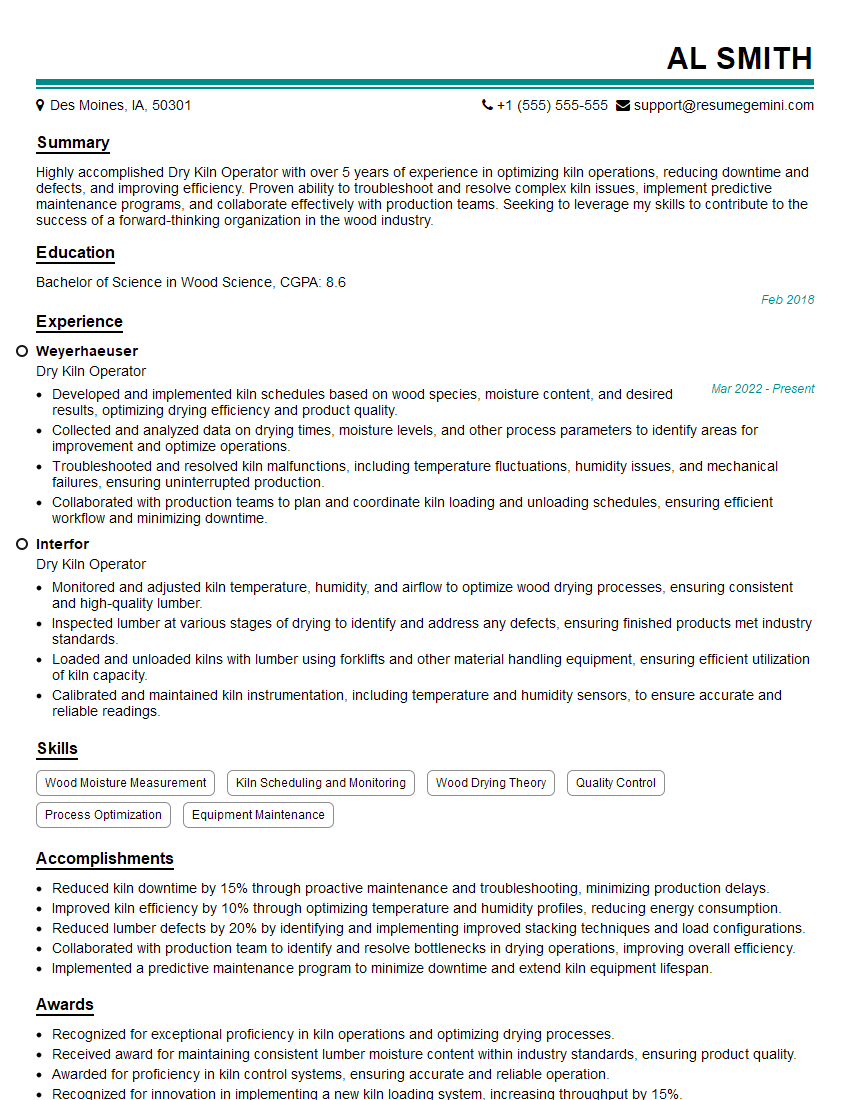

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Kiln Operator

1. What are the primary responsibilities of a Dry Kiln Operator?

As a Dry Kiln Operator, my core responsibilities encompass:

- Monitoring and controlling kiln operations, including temperature, humidity, and airflow.

- Conducting regular inspections and maintenance checks to ensure kiln equipment is functioning optimally.

- Maintaining accurate records of kiln conditions and lumber moisture content.

- Adjusting kiln settings and schedules to achieve the desired drying specifications for different lumber species.

- Coordinating with other departments, such as production and maintenance, to ensure smooth kiln operations.

2. Describe the scientific principles behind the lumber drying process?

Moisture Diffusion

- Water molecules migrate from areas of higher moisture content to areas of lower moisture content.

- Therefore, controlling the temperature and humidity in the kiln promotes moisture evaporation and diffusion.

Heat and Mass Transfer

- Heat transfer from the kiln air to the lumber increases the lumber temperature.

- Increased temperature accelerates the rate of moisture evaporation.

- Air circulation facilitates the movement of moisture-laden air out of the kiln.

3. How do you determine the optimal drying schedule for a given lumber species?

Selecting the optimal drying schedule involves considering several factors:

- Lumber species: Different species have varying drying characteristics, such as density and moisture content.

- Target moisture content: The desired moisture level for the final product.

- Kiln capacity and airflow: The physical constraints of the kiln and its airflow capabilities.

- Weather conditions: External temperature and humidity can influence the drying process.

- Drying defects: The schedule should minimize the risk of drying defects like case hardening, honeycombing, and surface checking.

4. Explain the purpose and operation of kiln sensors?

Kiln sensors play a crucial role in monitoring and controlling kiln conditions:

- Temperature sensors: Measure the temperature inside the kiln and provide real-time feedback.

- Humidity sensors: Determine the moisture content of the kiln air, indicating the drying rate.

- Moisture content sensors: Directly measure the moisture content of the lumber being dried.

- Airflow sensors: Monitor the velocity and volume of air circulating within the kiln.

- These sensors provide essential data to make informed adjustments to kiln settings and maintain optimal drying conditions.

5. What is case hardening, and how can you prevent it during the lumber drying process?

Case hardening is a drying defect that occurs when the outer layers of lumber dry faster than the inner core, creating internal stresses.

Preventive measures include:

- Gradual drying: Implementing a drying schedule that starts with mild conditions and gradually increases intensity.

- Sufficient airflow: Maintaining proper air circulation to promote uniform drying throughout the lumber.

- Stress relief: Utilizing techniques like steaming or vacuum drying to reduce internal stresses.

- Moisture equalization: Allowing the lumber to rest after drying to allow moisture to redistribute.

6. Describe the quality control procedures you follow to ensure the accuracy of kiln operations?

Quality control is crucial in Dry Kiln operations:

- Regular calibration: Calibrating kiln sensors and instruments to ensure accurate readings.

- Data recording: Maintaining comprehensive records of kiln conditions, lumber moisture content, and any deviations.

- Sample testing: Periodically testing lumber samples to verify moisture content and identify any drying defects.

- Visual inspection: Conducting visual checks of lumber for any signs of damage or defects.

- Customer feedback: Gathering feedback from customers to identify areas for improvement and ensure satisfaction.

7. How do you handle unexpected events or equipment malfunctions during kiln operations?

Unexpected events require quick and decisive action:

- Safety first: Prioritizing the safety of personnel and equipment by addressing any immediate hazards.

- Rapid troubleshooting: Identifying the root cause of the issue through logical analysis and systematic inspection.

- Temporary measures: Implementing temporary solutions to stabilize kiln conditions and prevent further damage.

- Repair or maintenance: Coordinating with maintenance personnel or external contractors to repair or replace faulty equipment.

- Communication: Keeping management and relevant parties informed of the situation and progress of resolution.

8. What are your strategies for optimizing energy efficiency in kiln operations?

Optimizing energy efficiency reduces operational costs and environmental impact:

- Kiln scheduling: Planning lumber loading and drying schedules to minimize energy consumption.

- Insulation and sealing: Ensuring proper insulation and sealing of the kiln to minimize heat loss.

- Heat recovery systems: Utilizing heat exchangers or thermal fluid systems to recover waste heat.

- Variable speed fans: Implementing fans with variable speed drives to adjust airflow based on demand.

- Monitoring and analysis: Continuously monitoring energy consumption and analyzing data to identify areas for improvement.

9. How do you stay up-to-date with advancements in the lumber drying industry?

Continuous learning is essential for professional growth:

- Industry publications: Reading trade magazines, journals, and technical reports to stay informed about best practices.

- Conferences and seminars: Attending industry events to network with experts and learn about the latest technologies.

- Online resources: Utilizing websites, forums, and online courses to access up-to-date information.

- Collaboration: Engaging with colleagues, seeking advice, and sharing knowledge to stay abreast of industry trends.

- Research and innovation: Exploring new techniques and technologies to improve drying efficiency and quality.

10. How do you ensure the environmental compliance of kiln operations?

Environmental compliance is of utmost importance:

- Permitting and regulations: Adhering to all applicable environmental permits and regulations.

- Emissions control: Implementing measures to minimize air, water, and noise pollution from kiln operations.

- Waste management: Properly disposing of waste products, such as sawdust and kiln dust, in an environmentally responsible manner.

- Regular inspections: Conducting regular inspections of equipment and processes to ensure compliance with environmental standards.

- Employee training: Educating employees about environmental responsibilities and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Kiln Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Kiln Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dry Kiln Operators are responsible for the operation and maintenance of kilns used to dry lumber. They monitor the kiln’s temperature, humidity, and airflow to ensure that the lumber is dried properly.

1. Operate and maintain dry kilns

intro paragraph

- Monitor kiln temperature, humidity, and airflow

- Adjust kiln controls to maintain desired drying conditions

2. Load and unload kilns

intro paragraph

- Use forklifts or other equipment to load and unload lumber from kilns

- Stack lumber in kilns to promote proper drying

3. Inspect lumber

intro paragraph

- Inspect lumber for defects before and after drying

- Identify and remove any defective lumber

4. Maintain kiln equipment

intro paragraph

- Clean and lubricate kiln equipment

- Repair or replace kiln parts as needed

Interview Tips

Preparing for an interview is critical to making a great impression and increasing your chances of getting the job. Here are a few tips to help you prepare for your Dry Kiln Operator interview:

1. Research the company and the position

Take some time to research the company you’re interviewing with and the specific position you’re applying for. This will help you understand the company’s culture and the skills and experience they’re looking for in a Dry Kiln Operator.

- Visit the company’s website

- Read the job description carefully

- Talk to people in your network who work for the company

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer questions

- Prepare examples of your skills and experience

- Be honest and authentic in your answers

3. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office setting.

- Choose neutral colors like black, navy, or gray

- Avoid wearing anything too revealing or too casual

- Make sure your clothes fit well and are comfortable

4. Be on time

Punctuality is important for any job interview, but it’s especially important for a Dry Kiln Operator interview. This is because Dry Kiln Operators are responsible for maintaining the kiln’s temperature and humidity, and being late could disrupt the drying process.

- Plan your route and leave early

- Allow for extra time in case of traffic or other delays

- If you’re running late, call the interviewer and let them know

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dry Kiln Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!