Are you gearing up for a career in Dry Mixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dry Mixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

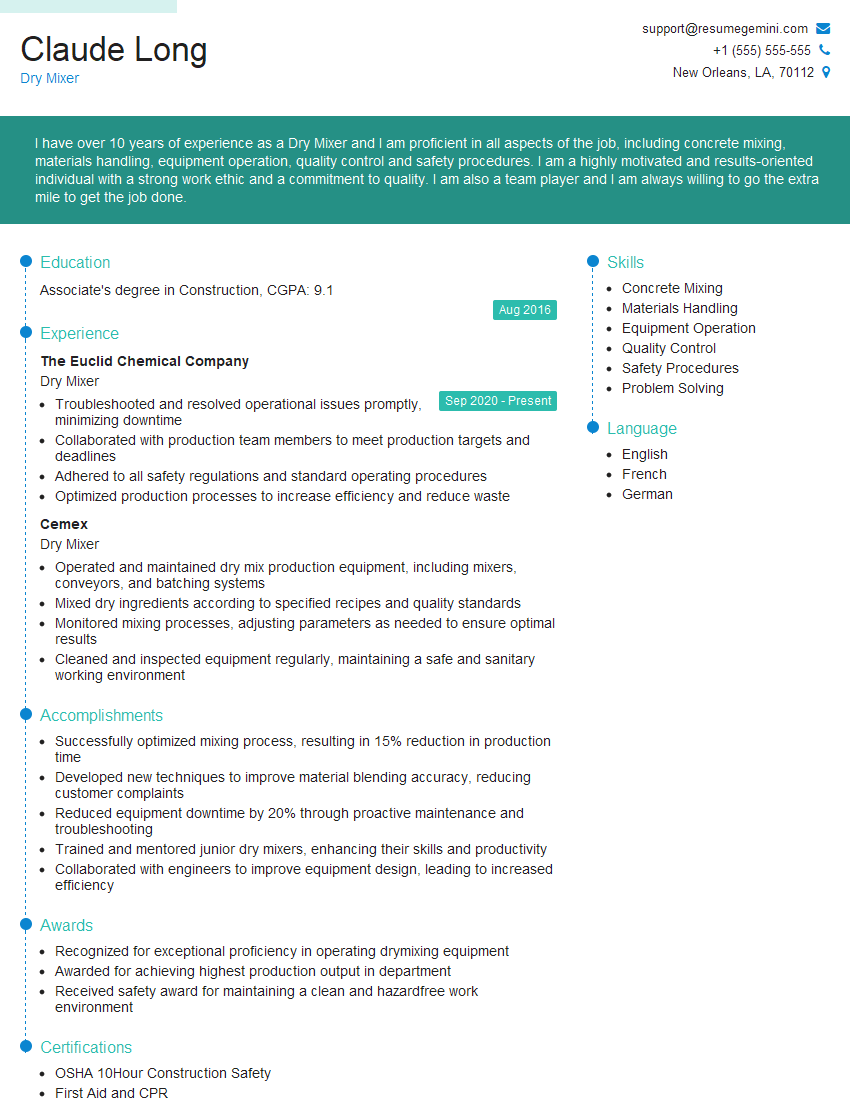

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Mixer

1. what are the duties and responsibilities of a Dry Mixer?

As a Dry Mixer, my primary responsibilities include:

- Measuring and weighing raw materials and additives

- Operating dry mixing equipment

- Monitoring the mixing process to ensure the desired blend is achieved

- Maintaining equipment and the work area

- Following safety and quality control procedures

2. describe the dry mixing process, including the different types of mixers and their applications?

Types of Mixers

- Ribbon Blender: Suitable for blending dry powder ingredients with different densities and particle sizes.

- Tumble Blender: Ideal for blending delicate or free-flowing materials.

- Cone Blender: Used for mixing large batches of dry solids.

- Lodige Mixer: Capable of mixing both dry and wet ingredients, and handling a wide range of materials.

Mixing Process

The dry mixing process typically involves the following steps:

- Measuring and weighing raw materials

- Loading the materials into the mixer

- Setting the mixer parameters (speed, time, etc.)

- Initiating the mixing cycle

- Monitoring and adjusting the mixing process as needed

3. what are the common challenges faced in dry mixing, and how do you overcome them?

Some common challenges faced in dry mixing include:

- Achieving a uniform blend: Overcome by optimizing mixing parameters and ensuring proper equipment maintenance.

- Avoiding segregation: Using anti-segregation agents or special mixing techniques.

- Handling dusty materials: Implementing dust control measures and proper ventilation.

- Maintaining equipment uptime: Regular maintenance, timely repairs, and preventive measures.

4. explain the quality control procedures involved in dry mixing?

Quality control procedures in dry mixing include:

- Raw material verification: Inspecting and testing incoming materials for compliance.

- Process monitoring: Regularly checking mixing parameters and making adjustments as necessary.

- Product testing: Conducting lab analyses to verify blend uniformity and other quality attributes.

- Documentation maintenance: Accurately recording all mixing data and testing results.

5. what are the safety precautions that must be taken when operating dry mixing equipment?

Safety precautions for operating dry mixing equipment include:

- Wearing appropriate personal protective equipment (e.g., gloves, safety glasses, respirators)

- Following lockout/tagout procedures before maintenance or repairs

- Preventing access to moving parts and rotating machinery

- Maintaining a clean and organized work area

- Reporting any equipment malfunctions or potential hazards promptly

6. Describe your experience with troubleshooting and resolving issues in dry mixing operations?

I have faced and resolved various issues in dry mixing operations, including:

- Uneven blending: Identified and corrected equipment malfunctions, adjusted mixing parameters, or introduced anti-segregating agents.

- Equipment breakdowns: Performed routine maintenance, identified and replaced faulty components, and collaborated with technicians for major repairs.

- Dust accumulation: Implemented dust control measures, such as using baghouses or electrostatic precipitators, and ensured regular cleaning.

- Quality deviations: Conducted thorough investigations, identified the root cause, and implemented corrective actions to prevent recurrences.

7. Explain the importance of effective communication and teamwork in dry mixing operations?

Effective communication and teamwork are crucial in dry mixing operations for:

- Clear instruction exchange: Ensuring operators understand mixing procedures and safety protocols.

- Problem resolution: Sharing knowledge and collaborating to identify and resolve issues quickly.

- Process optimization: Brainstorming ideas, evaluating results, and implementing improvements as a team.

- Maintenance coordination: Scheduling maintenance activities, assigning tasks, and communicating equipment status.

8. Describe your experience with continuous improvement and optimizing dry mixing processes?

I am committed to continuous improvement and have implemented several initiatives to optimize dry mixing processes, including:

- Process audits: Regularly evaluating operations to identify areas for improvement.

- Equipment upgrades: Introducing new technologies or upgrading existing equipment to enhance efficiency.

- Training programs: Providing ongoing training to operators on best practices and troubleshooting techniques.

- Data analysis: Monitoring key performance indicators and using data to identify trends and implement targeted improvements.

9. Explain the role of innovation in the dry mixing industry, and how you stay updated with the latest advancements?

Innovation plays a vital role in the dry mixing industry, and I stay updated with the latest advancements through:

- Industry conferences: Attending events and workshops to connect with experts and learn about emerging technologies.

- Trade journals and publications: Subscribing to industry magazines and accessing online forums to stay informed on research and development.

- Collaboration with equipment manufacturers: Partnering with suppliers to gain insights into new products and innovations.

- Continuing education: Pursuing additional training or certification programs to expand my knowledge and skills.

10. Why are you interested in joining our company for the Dry Mixer position?

I am eager to join your company as a Dry Mixer for several reasons:

- Reputable organization: Your company is renowned for its commitment to quality and innovation in the industry.

- Growth opportunities: I believe that this role will provide me with ample opportunities to develop my skills and contribute to the company’s success.

- Alignment with my career goals: This position aligns perfectly with my long-term career aspirations in the dry mixing field.

- Company culture: I am impressed by your company’s emphasis on employee well-being, training, and teamwork, which resonates with my values.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dry Mixers are responsible for operating and maintaining mixers that blend dry materials. They work in manufacturing facilities, where they produce a variety of products, including food, pharmaceuticals, and chemicals.

1. Operate and Maintain Mixers

Dry Mixers operate and maintain mixers by following established procedures. They ensure that the mixers are clean and running properly. They also troubleshoot and repair any problems that may arise.

- Operate mixers to blend dry materials according to specifications.

- Monitor mixers to ensure that they are operating properly.

- Clean and maintain mixers to keep them in good working condition.

2. Control Product Quality

Dry Mixers control product quality by ensuring that the materials are blended properly. They also test the products to ensure that they meet specifications.

- Test products to ensure that they meet specifications.

- Adjust mixer settings to improve product quality.

- Identify and correct any problems that may arise during the mixing process.

3. Safety Compliance

Dry Mixers must comply with all safety regulations. They follow established procedures for handling hazardous materials and using equipment.

- Follow established procedures for handling hazardous materials.

- Use equipment safely and properly.

- Report any accidents or injuries to the supervisor.

4. Teamwork and Communication

Dry Mixers work as part of a team to produce products. They communicate with other team members to ensure that the process runs smoothly.

- Work as part of a team to produce products.

- Communicate with other team members to ensure that the process runs smoothly.

- Follow instructions from supervisors.

Interview Tips

Preparing for a Dry Mixer interview can be daunting, but with the right tips, you can increase your chances of success. Start by practicing your answers to the most common interview questions.

1. Research the Company

Before your interview, take some time to research the company. This will help you understand the company’s culture and values. You can also learn about the specific products that the company produces. This will help you answer questions about your qualifications and experience.

- What is the company’s history?

- What are the company’s goals?

- What are the company’s products?

2. Practice Answering Common Interview Questions

There are a few common interview questions that you can expect to be asked. These questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with mixers?

Take some time to think about your answers to these questions. You can also practice answering them out loud. This will help you feel more confident when you are in the interview.

3. Dress Professionally

First impressions matter. Make sure to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Be well-groomed.

4. Be Polite and Courteous

Be polite and courteous to everyone you meet during your interview. This includes the receptionist, the hiring manager, and other employees. Remember, you are representing yourself and the company. Make sure to be a good ambassador for both.

- Be polite and courteous to everyone you meet.

- Smile and make eye contact.

- Be respectful of other people’s time.

5. Follow Up

After your interview, send a thank-you note to the hiring manager. This is a great way to show your appreciation for the opportunity to interview. It is also a chance to reiterate your interest in the position.

- Send a thank-you note to the hiring manager.

- Reiterate your interest in the position.

- Ask if there is anything else you can provide.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dry Mixer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.