Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dry Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dry Molder so you can tailor your answers to impress potential employers.

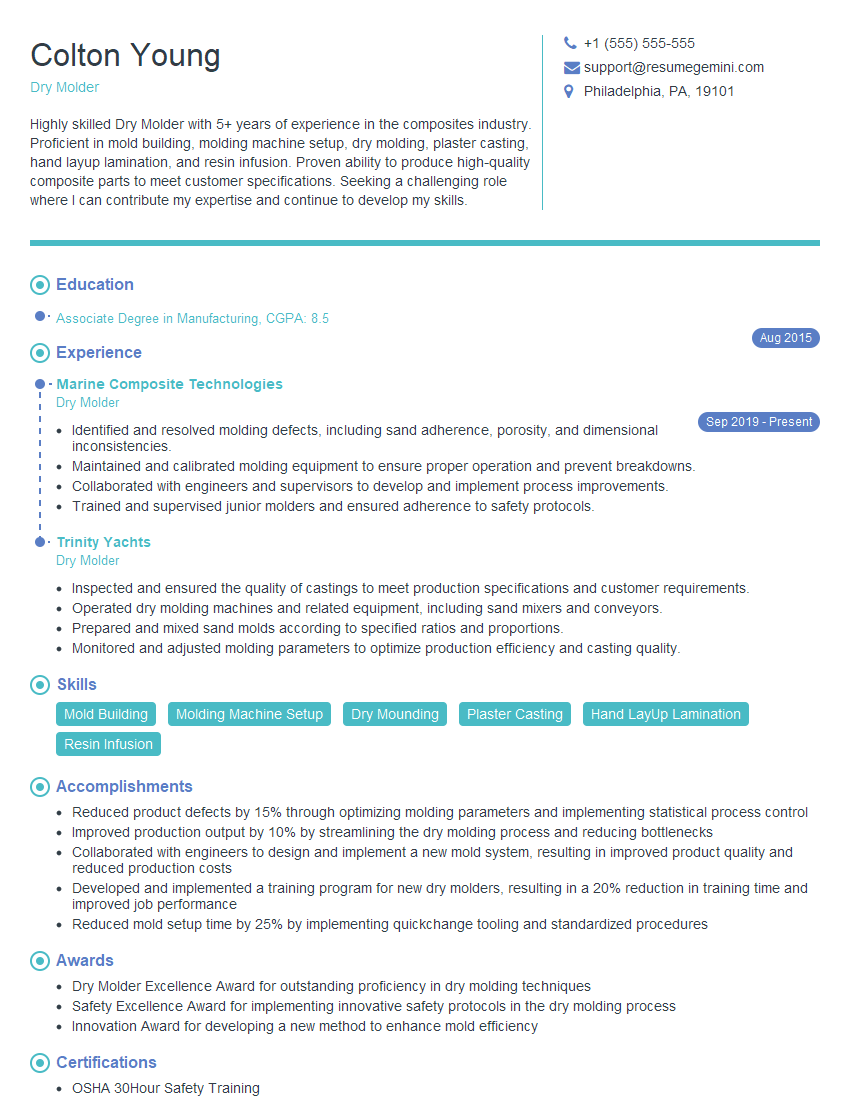

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Molder

1. What are the responsibilities of a Dry Molder?

- Preparing molds for pouring by cleaning, releasing agents, and creating parting lines

- Monitoring the molding process to ensure that the product meets specifications

- Maintaining and repairing molding equipment to ensure efficient operation

- Inspecting finished products to ensure that they meet quality standards

- Following safety procedures and maintaining a clean and organized work area

2. What types of materials are used in dry molding?

Sand-based materials

- Green sand

- Dry sand

- Chemically bonded sand

Metallic materials

- Cast iron

- Steel

- Aluminum

Other materials

- Plastics

- Ceramics

- Composites

3. What are the different types of molding processes used in dry molding?

- Gravity casting

- Pressure casting

- Centrifugal casting

- Vacuum casting

- Investment casting

4. What are the advantages and disadvantages of dry molding?

Advantages

- High accuracy and precision

- Excellent surface finish

- Suitable for a wide range of materials

- Relatively low cost

Disadvantages

- Slower production rates compared to other molding processes

- Can be labor-intensive

- Requires skilled labor

5. What are the key quality control measures in dry molding?

- Checking the dimensions of the mold

- Verifying the material composition

- Monitoring the temperature of the mold and molten material

- Inspecting the surface finish of the finished product

- Measuring the hardness and strength of the finished product

6. What are the safety precautions that should be taken when working in a dry molding environment?

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator

- Using proper ventilation to remove dust and fumes

- Keeping the work area clean and organized

- Following established safety procedures

- Being aware of potential hazards, such as hot metal and sharp edges

7. How do you troubleshoot common problems that occur in dry molding?

- Defects in the finished product, such as cracks, porosity, or shrinkage

- Problems with the mold, such as sticking or flashing

- Equipment malfunctions

- Material handling issues

8. What are the latest trends in dry molding technology?

- Automation and robotics

- Advanced materials and coatings

- Improved quality control techniques

- Sustainability and environmental consciousness

9. What are your strengths and weaknesses as a Dry Molder?

Strengths

- Strong understanding of dry molding principles and techniques

- Experience in working with a variety of materials

- Excellent attention to detail

- Ability to troubleshoot and resolve problems quickly

- Commitment to safety and quality

Weaknesses

- Limited experience with certain types of molding machines

- Need to improve efficiency in some areas

10. What are your career goals and how do you see this role helping you achieve them?

- To become a lead Dry Molder and eventually a supervisor

- To gain experience in different aspects of dry molding

- To contribute to the success of the company

- To develop my skills and knowledge in the field of dry molding

- To learn from experienced professionals and expand my network

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Dry Molder is responsible for operating and maintaining dry molding equipment, ensuring the production of high-quality castings. This role requires a combination of technical expertise in molding processes and strong attention to detail.

1. Molding and Production

The Dry Molder must possess a strong understanding of sand handling systems and casting processes. Key responsibilities include:

- Preparing and operating dry molding machines, including core making, pattern setting, and mold assembly

- Monitoring and adjusting process parameters to optimize casting quality and minimize defects

- Troubleshooting and resolving production issues to maintain efficient operations

2. Quality Control

The Dry Molder is responsible for maintaining the quality of castings. This involves:

- Inspecting raw materials and finished products to ensure compliance with specifications

- Conducting dimensional and metallurgical testing to verify product quality

- Collaborating with quality assurance personnel to identify and resolve quality issues

3. Equipment Maintenance

Maintaining equipment reliability is crucial for the Dry Molder. Responsibilities include:

- Performing scheduled and preventive maintenance on molding equipment

- Troubleshooting and repairing equipment breakdowns

- Collaborating with maintenance technicians to ensure optimal equipment performance

4. Safety and Compliance

The Dry Molder is responsible for adhering to safety protocols and environmental regulations:

- Following established safety procedures and wearing appropriate safety gear

- Complying with environmental regulations related to waste disposal and emission control

- Promoting a safe and healthy work environment for colleagues

Interview Preparation Tips

Preparing thoroughly for your Dry Molder interview can significantly increase your chances of success. Here are some essential tips:

1. Research the Company and Industry

- Learn about the company’s history, products, and industry standing.

- Familiarize yourself with current trends and advancements in the dry molding industry.

2. Practice Answering Common Interview Questions

- Review common interview questions related to molding processes, quality control, and safety.

- Prepare thoughtful and specific answers that showcase your skills and experience.

3. Use the STAR Method

- Structure your answers using the STAR method (Situation, Task, Action, Result).

- Provide specific examples from your work experience to demonstrate your abilities.

4. Highlight Your Skills and Qualifications

- Emphasize your technical expertise in dry molding processes and equipment maintenance.

- Highlight your strong attention to detail and commitment to quality assurance.

5. Be Enthusiastic and Confident

- Demonstrate your passion for the dry molding industry and your eagerness to contribute to the company’s success.

- Maintain a positive and confident demeanor throughout the interview.

6. Ask Thoughtful Questions

- Prepare insightful questions about the company, the role, and the industry.

- Asking questions shows your engagement and interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dry Molder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.