Are you gearing up for a career in Dry-Placer Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dry-Placer Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

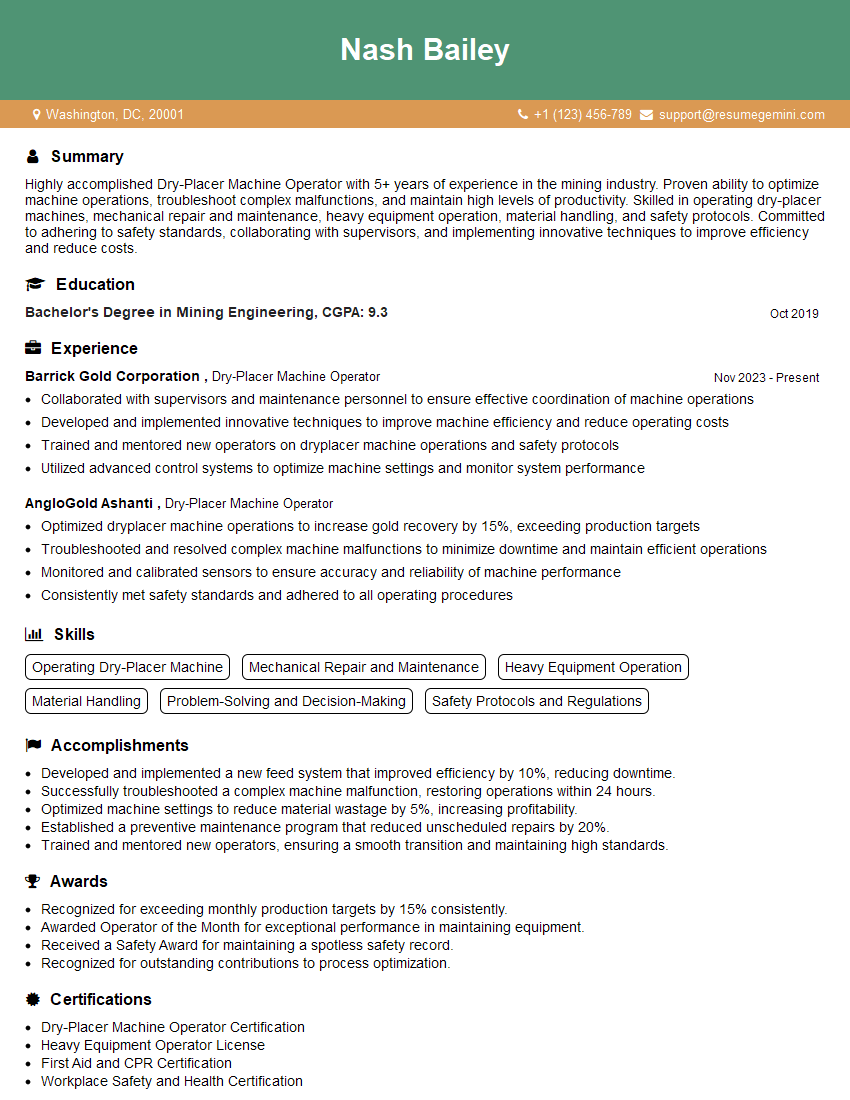

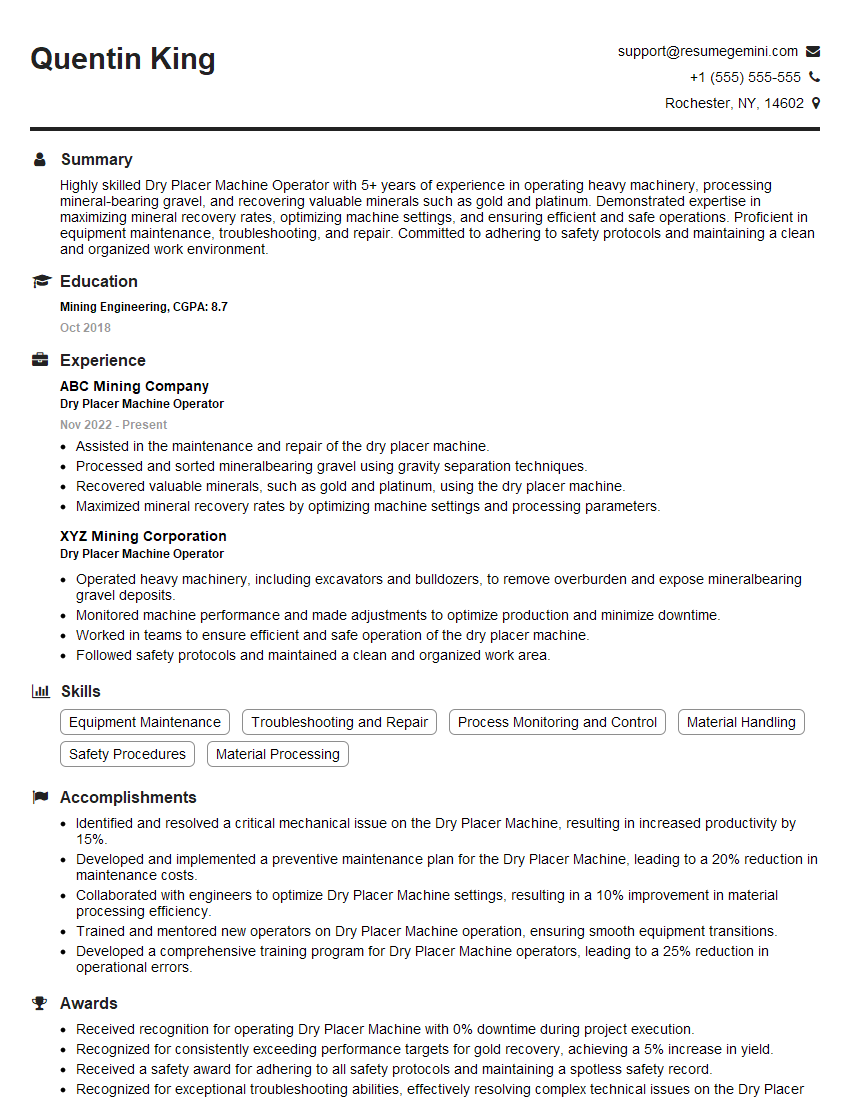

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry-Placer Machine Operator

1. What are the key responsibilities of a Dry-Placer Machine Operator?

- Operating and monitoring dry-placer machines to separate valuable minerals from raw materials.

- Adjusting machine settings to optimize separation efficiency and minimize losses.

- Maintaining and troubleshooting dry-placer machines to ensure smooth operation.

- Sampling and analyzing processed materials to monitor performance and identify areas for improvement.

2. Describe the different types of dry-placer machines and their applications.

Centrifugal Dry Placer

- Separates minerals based on centrifugal force.

- Used for processing dry materials with high specific gravity minerals, such as gold and platinum.

Pneumatic Dry Placer

- Uses air pressure to separate minerals.

- Suitable for processing materials with fine particles, such as beach sands and desert deposits.

Gravity Dry Placer

- Employs gravity to separate minerals.

- Used for processing materials with coarse particles, such as river gravel and placer deposits.

3. What are the common issues that can occur during dry-placer machine operation and how do you troubleshoot them?

- Clogged feed chutes or screens: Check for blockages and clear them.

- Inefficient separation: Adjust machine settings, such as fan speed or water flow, to improve separation.

- Machine breakdowns: Identify the fault, consult manuals, and perform repairs or call for maintenance.

4. How do you ensure the safety of yourself and others while operating dry-placer machines?

- Wearing appropriate safety gear, such as hard hat, goggles, and gloves.

- Following established safety protocols and procedures.

- Inspecting machines regularly for potential hazards.

- Maintaining a clean and organized work area.

5. What factors influence the efficiency of dry-placer machine operation?

- Material characteristics: Particle size, density, and shape.

- Machine settings: Fan speed, water flow, and vibration intensity.

- Environmental conditions: Temperature, humidity, and wind.

6. How do you calibrate and maintain dry-placer machines to ensure accurate and consistent separation?

- Following manufacturer’s calibration guidelines.

- Cleaning and inspecting machines regularly for wear and tear.

- Replacing worn or damaged parts as needed.

- Monitoring machine performance and making adjustments to optimize efficiency.

7. What is the role of sampling and analysis in dry-placer machine operation?

- Sampling: Collect representative samples at different stages of processing.

- Analysis: Conduct tests, such as sieve analysis and X-ray diffraction, to determine mineral composition and particle size distribution.

- Process control: Use analysis results to adjust machine settings and optimize separation.

8. Describe the environmental regulations and safety standards that apply to dry-placer machine operation.

- Environmental Protection Agency (EPA) regulations: Regarding dust and noise pollution.

- Occupational Safety and Health Administration (OSHA) standards: Concerning worker safety and hazardous materials handling.

- Local regulations: Specific to the region or municipality.

9. What are the career advancement opportunities for Dry-Placer Machine Operators?

- Production Supervisor: Oversee dry-placer machine operations and staff.

- Maintenance Technician: Specialize in maintaining and repairing dry-placer machines.

- Process Engineer: Optimize dry-placer machine operations to improve efficiency and yield.

- Managerial roles: In mining or mineral processing operations.

10. Why are you interested in working as a Dry-Placer Machine Operator for our company?

Here, you can tailor your answer to the specific company and position.

- Highlight your relevant skills and experience.

- Express your interest in the company’s products or industry.

- Explain how you can contribute to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry-Placer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry-Placer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dry-Placer Machine Operator is primarily responsible for operating and maintaining dry-placer machines used in the mining industry to separate valuable minerals from soil and rock. Key responsibilities include:

1. Machine Operation and Maintenance

Operate dry-placer machines efficiently to separate minerals based on specific gravity and particle size.

- Monitor machine performance, make necessary adjustments, and troubleshoot issues.

- Perform routine maintenance on equipment, including lubrication, cleaning, and repairs.

2. Material Handling

Load and unload materials into the dry-placer machine.

- Inspect materials to ensure they meet processing specifications.

- Dispose of waste materials and byproducts safely and efficiently.

3. Quality Control and Monitoring

Monitor the quality of the processed materials.

- Perform quality checks to ensure products meet standards.

- Maintain accurate records of machine performance and production.

4. Safety and Compliance

Adhere to all safety regulations and protocols.

- Wear appropriate safety gear and maintain a clean and organized work environment.

- Follow established procedures for handling and storing materials.

Interview Tips

Preparing for a Dry-Placer Machine Operator interview can increase your chances of success. Here are some effective tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the mining industry and the company you’re applying to. Research their operations, products, and key players.

- This knowledge will help you connect your skills to the company’s needs and demonstrate your interest in the role.

2. Practice Your Technical Skills

Review the key job responsibilities and ensure you have a strong understanding of dry-placer machine operations and maintenance.

- Consider preparing specific examples of your experience operating and troubleshooting similar equipment.

3. Highlight Your Attention to Detail

Emphasize your ability to follow instructions precisely and monitor quality closely. Provide examples of your success in maintaining high-quality standards in previous roles.

- Hiring managers will be looking for candidates who take pride in their work and are dedicated to producing accurate results.

4. Prepare for Safety Questions

Safety is paramount in mining operations. Be prepared to discuss your safety practices and knowledge of industry regulations.

- Share examples of your commitment to maintaining a safe work environment and preventing accidents.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dry-Placer Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!