Are you gearing up for a career in Dry Plasterer Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dry Plasterer Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

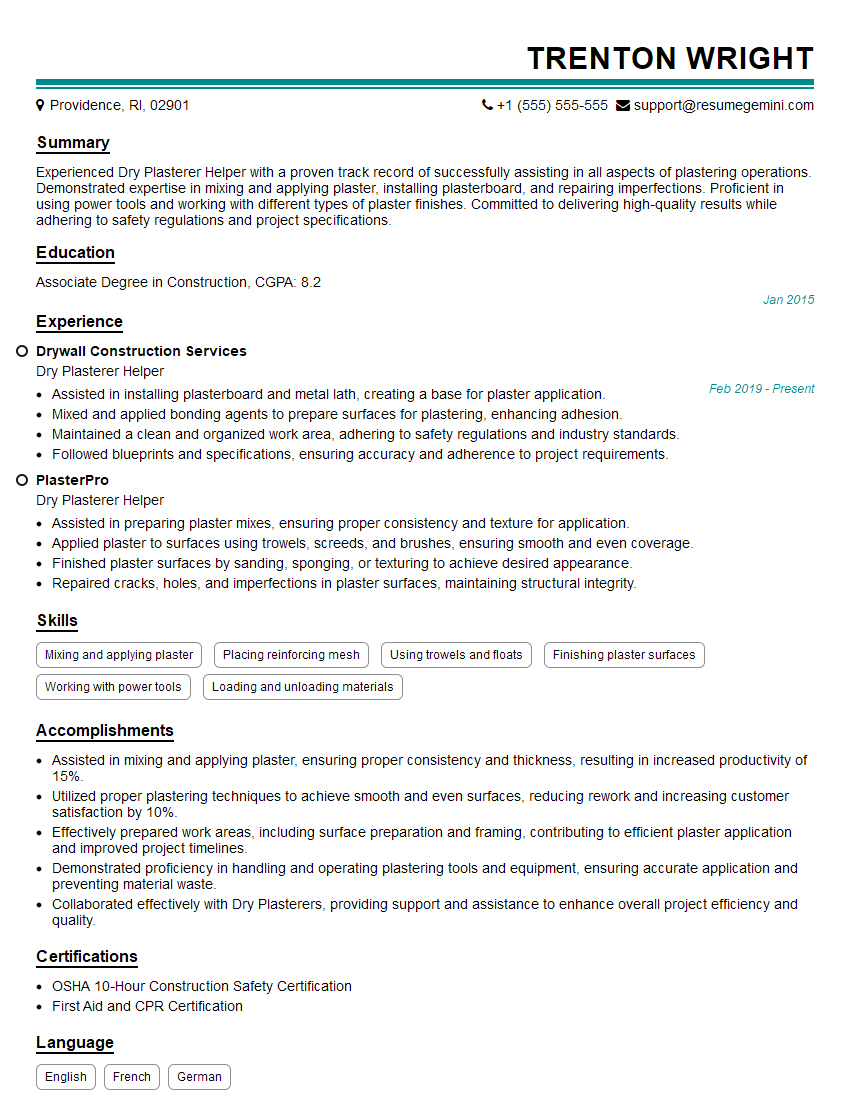

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Plasterer Helper

1. What are the different types of plastering tools and how do you use them?

- Trowel: Used for applying and smoothing plaster.

- Float: Used for leveling and finishing plaster.

- Hawk: Used for holding plaster and transferring it to the trowel.

- Sponge: Used for cleaning tools and plaster surfaces.

2. How do you prepare a surface for plastering?

Preparing the surface

- Remove any dirt, dust, or debris from the surface.

- Repair any cracks or holes in the surface.

- Prime the surface with a primer that is compatible with the plaster.

Applying the plaster

- Apply the plaster to the surface using a trowel.

- Use a float to level and finish the plaster.

- Smooth the plaster with a sponge.

3. What are the different types of plaster and how are they used?

- Gypsum plaster: Made from gypsum and water, it is a versatile plaster that can be used for a variety of applications.

- Lime plaster: Made from lime and sand, it is a durable plaster that is often used for exterior applications.

- Cement plaster: Made from cement and sand, it is a strong plaster that is often used for commercial applications.

4. How do you mix plaster?

- Add water to the plaster powder in a mixing tub.

- Mix the plaster until it reaches the desired consistency.

- Allow the plaster to slake for a few minutes before using it.

5. What are the safety precautions that you need to take when working with plaster?

- Wear a dust mask to avoid inhaling plaster dust.

- Wear gloves to protect your hands from plaster.

- Wear eye protection to protect your eyes from plaster dust and particles.

- Keep the work area well-ventilated.

6. What are the common problems that you may encounter when plastering and how do you solve them?

- Cracks: Cracks can be caused by a variety of factors, such as improper mixing of the plaster, inadequate drying time, or movement of the substrate.

- Blisters: Blisters are caused by air bubbles trapped in the plaster. They can be removed by scraping them off the surface of the plaster.

- Efflorescence: Efflorescence is a white or crystalline deposit that can form on the surface of the plaster. It is caused by the presence of salts in the plaster.

7. What are the different types of finishes that can be applied to plaster?

- Smooth finish: A smooth finish is achieved by troweling the plaster until it is smooth and even.

- Textured finish: A textured finish is achieved by adding texture to the plaster using a variety of tools, such as a sponge or a trowel.

- Painted finish: A painted finish is achieved by applying paint to the plaster.

8. What are the different types of plastering tools and how do you use them?

- Trowel: Used for applying and smoothing plaster.

- Float: Used for leveling and finishing plaster.

- Hawk: Used for holding plaster and transferring it to the trowel.

- Sponge: Used for cleaning tools and plaster surfaces.

9. How do you prepare a surface for plastering?

Preparing the surface

- Remove any dirt, dust, or debris from the surface.

- Repair any cracks or holes in the surface.

- Prime the surface with a primer that is compatible with the plaster.

Applying the plaster

- Apply the plaster to the surface using a trowel.

- Use a float to level and finish the plaster.

- Smooth the plaster with a sponge.

10. What are the different types of plaster and how are they used?

- Gypsum plaster: Made from gypsum and water, it is a versatile plaster that can be used for a variety of applications.

- Lime plaster: Made from lime and sand, it is a durable plaster that is often used for exterior applications.

- Cement plaster: Made from cement and sand, it is a strong plaster that is often used for commercial applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Plasterer Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Plasterer Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dry Plasterer Helper assists Dry Plasterers in various aspects of plastering and drywall installation projects. Their primary responsibilities include:

1. Material Handling

Unload and transport materials to the worksite, such as plasterboard, joint compound, and tools.

- Operate equipment like forklifts or hand trucks to move heavy materials efficiently.

- Maintain a clean and organized work area by disposing of waste and debris.

2. Plasterboard Installation

Assist in the cutting, fitting, and installation of plasterboard on walls and ceilings.

- Use measuring tapes and levels to ensure accurate placement and alignment of plasterboards.

- Apply adhesive or screws to secure plasterboards onto surfaces.

3. Joint Finishing

Apply joint compound to fill and smooth joints between plasterboards.

- Mix and prepare joint compound to the desired consistency.

- Use taping knives and sanding tools to create a seamless finish and prepare surfaces for painting.

4. Cleaning and Maintenance

Clean and maintain tools and equipment used in plastering operations.

- Ensure that equipment is in good working condition by performing regular inspections and maintenance.

- Clean work areas and dispose of hazardous materials according to safety protocols.

Interview Tips

To prepare for a Dry Plasterer Helper interview, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and the specific requirements of the Dry Plasterer Helper role. This knowledge will help you speak intelligently about your qualifications and how you align with the company’s needs.

Example: Research the company’s recent construction projects to gain insights into their plastering techniques and standards.

2. Highlight Relevant Skills and Experience

Emphasize your abilities in material handling, plasterboard installation, joint finishing, and cleaning operations. Quantify your experience whenever possible to demonstrate your impact on previous projects.

Example: “In my previous role, I assisted in the installation of over 100,000 square feet of plasterboard, resulting in a significant reduction in project completion time.”

3. Demonstrate Safety Awareness

Plastering involves handling heavy materials and working in potentially hazardous environments. Highlight your safety consciousness by describing your adherence to safety protocols and your commitment to maintaining a safe work environment.

Example: “I always wear appropriate protective gear and follow established safety guidelines to prevent accidents and ensure the well-being of myself and others.”

4. Ask Insightful Questions

Asking thoughtful questions demonstrates your interest in the role and the company. Prepare questions that showcase your knowledge of the industry and seek clarification on the company’s expectations and project workflow.

Example: “Could you elaborate on the company’s preferred plastering methods and the types of projects I would be working on?”

5. Practice Common Interview Questions

Prepare for common interview questions by practicing your responses in advance. This will help you articulate your strengths and qualifications clearly and confidently.

Example: Practice answering questions about your teamwork abilities, problem-solving skills, and attention to detail.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Dry Plasterer Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Dry Plasterer Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.