Feeling lost in a sea of interview questions? Landed that dream interview for Dry Sand Molder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dry Sand Molder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

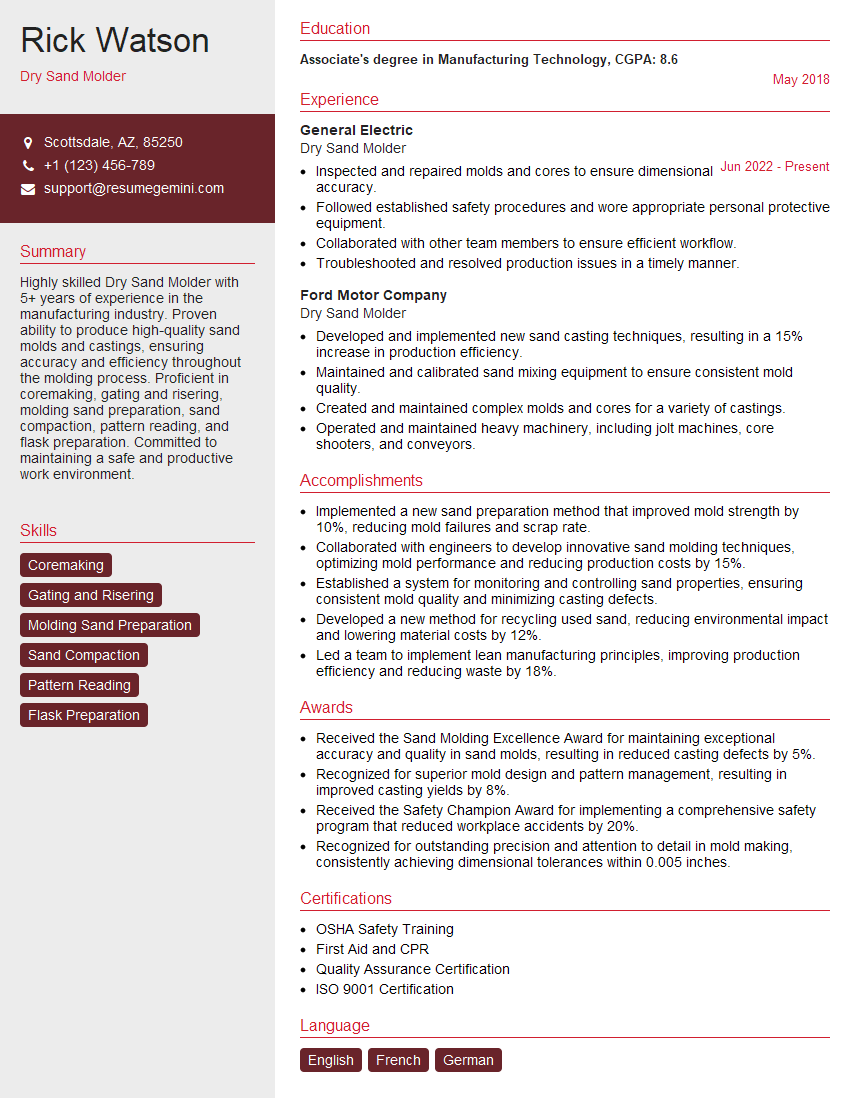

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dry Sand Molder

1. What is the importance of binder in dry sand molding?

- Binder provides strength to the mold, enabling it to withstand the pouring of molten metal.

- It helps in releasing the pattern from the mold without causing damage.

- Binder controls the permeability of the mold, allowing gases to escape during casting.

2. How do you ensure the accuracy and quality of the molds you produce?

Quality Checks

- Inspect the dimensions and shape of the pattern before molding.

- Check the sand mixture for proper moisture content and binder ratio.

- Evaluate the mold surface for any defects or imperfections.

Production Techniques

- Use high-quality materials and equipment.

- Follow established molding procedures and standards.

- Maintain the equipment regularly and make adjustments as needed.

3. What are the key factors to consider when choosing the appropriate dry sand molding method?

- The complexity of the casting.

- The size and weight of the casting.

- The type of metal being cast.

- The production volume required.

- The available equipment and resources.

4. How do you troubleshoot common problems encountered in dry sand molding, such as mold collapse or gas porosity?

- Mold Collapse: Check for insufficient binder, excessive moisture, or improper compaction.

- Gas Porosity: Ensure proper ventilation of the mold, adjust binder content, or use degassing agents.

5. What is the difference between green sand molding and dry sand molding, and when is each method preferred?

- Green Sand Molding: Uses moist sand, provides better surface finish, suitable for small to medium castings.

- Dry Sand Molding: Uses dry sand, allows for more intricate castings, preferred for large or complex castings.

6. How do you calculate the amount of sand and binder required for a specific mold?

- Determine the volume of the mold cavity.

- Apply a factor to account for sand expansion during molding.

- Calculate the weight of sand using its density.

- Determine the binder ratio as a percentage of the sand weight.

7. What safety precautions should be taken when working with dry sand molding equipment?

- Wear appropriate personal protective equipment (PPE).

- Operate equipment only if trained and authorized.

- Follow lockout/tagout procedures when servicing machinery.

- Maintain a clean and organized work area.

8. How do you handle and store dry sand materials to ensure their quality and prevent contamination?

- Store sand in dry, covered containers.

- Protect sand from moisture and foreign objects.

- Rotate sand stock to prevent settling and compaction.

- Inspect sand regularly for any changes in appearance or properties.

9. What is your experience with using different types of dry sand molding equipment, such as jolt molding machines or pattern draw machines?

- Explain your experience with specific equipment.

- Highlight your proficiency in operating and maintaining the machines.

- Discuss any troubleshooting or optimization techniques you have employed.

10. What are your strengths and weaknesses as a Dry Sand Molder?

Strengths

- Skilled in producing high-quality molds.

- Proficient in troubleshooting and solving production issues.

- Strong attention to detail and accuracy.

Weaknesses

- Limited experience with automated molding systems.

- Working in a fast-paced environment can sometimes lead to stress.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dry Sand Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dry Sand Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Dry Sand Molder fabricates metal castings from sand molds, following specifications and safety standards. Here are the essential job responsibilities:

1. Handling Molding Equipment

Operate and maintain molding machines, sifting and mixing equipment, and other tools used in the molding process.

- Ensure proper calibration of machines and ensure they are in good working condition.

- Troubleshoot and resolve any technical issues with equipment.

2. Mold Construction

Create sand molds using patterns and flasks, ensuring measurements and specifications are precise.

- Prepare sand mixtures and compact them into molds using molding machines or hand molding techniques.

- Insert pattern into the flask and secure it with clamps, ensuring alignment and stability.

- Monitor mold curing process to ensure proper hardening and strength.

3. Casting and Finishing

Pour molten metal into molds, monitor casting process, and perform finishing operations.

- Select and prepare appropriate pouring ladles and crucibles.

- Carefully pour molten metal into molds, maintaining proper temperature and flow.

- Inspect castings for defects, clean and smooth surfaces, and prepare them for further processing.

4. Quality Control

Conduct quality checks on molds and castings to ensure they meet specifications and standards.

- Measure dimensions, inspect surfaces, and identify any imperfections or deviations.

- Maintain records of inspections and report any inconsistencies to supervisors.

Interview Tips

Thoroughly prepare for your interview to present yourself confidently and highlight your skills and experience relevant to the Dry Sand Molder position:

1. Research the Company and Industry

Before the interview, research the company’s history, products or services, and industry standing. This knowledge will demonstrate your genuine interest and preparation.

- Visit the company’s website, read industry publications, and network with professionals in the field.

- Familiarize yourself with the specific job requirements and the company’s expectations for the role.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself” or “Why are you interested in this position?” Tailor your responses to highlight your qualifications and align them with the job requirements.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your skills and experience.

- Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

3. Prepare Industry-Specific Questions

Research industry-specific questions that showcase your knowledge and understanding of the molding process. This demonstrates your commitment to the field and your ability to contribute effectively.

- Questions about different types of molding techniques, such as green sand molding or investment casting.

- Questions about the properties and handling of different molding materials, such as sand and resins.

4. Highlight Safety and Quality Control

Emphasize your commitment to safety and quality control in your interview. These are critical aspects of the Dry Sand Molder role, and highlighting your adherence to standards will demonstrate your professionalism.

- Discuss your experience with safety protocols in a foundry environment.

- Explain your understanding of quality control processes and your attention to detail.

5. Ask Insightful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest and engagement. This shows the interviewer that you are genuinely interested in the position and the company.

- Inquire about the company’s growth plans or upcoming projects.

- Ask about the training and development opportunities available for employees.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Dry Sand Molder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Dry Sand Molder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.