Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dryer Feeder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dryer Feeder so you can tailor your answers to impress potential employers.

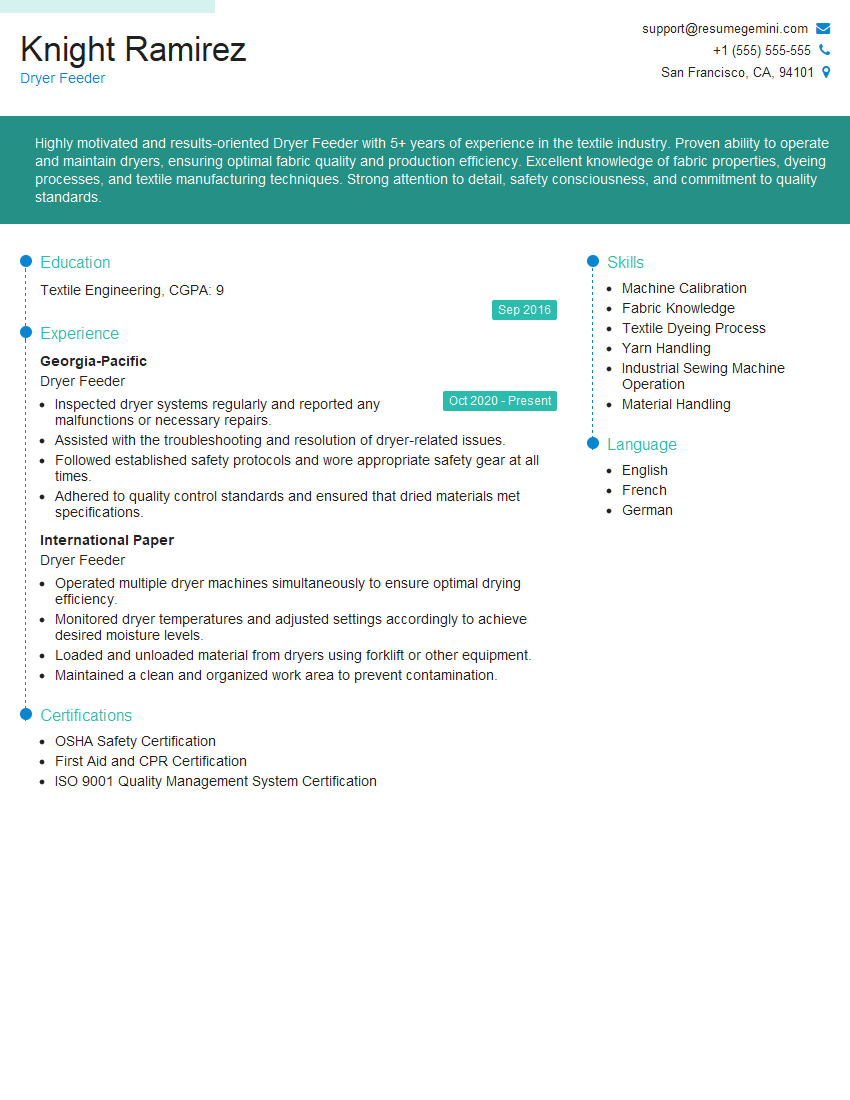

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dryer Feeder

1. What are the key responsibilities of a Dryer Feeder?

As a Dryer Feeder, my primary responsibilities include:

- Manually feeding materials into the dryer, ensuring a consistent and even flow.

- Monitoring the drying process to prevent over- or under-drying of materials.

- Maintaining the dryer and its related equipment, including cleaning, lubrication, and minor repairs.

- Adhering to safety protocols and regulations related to the operation of the dryer.

- Communicating with the production team to ensure smooth coordination and timely delivery of dried materials.

2. What types of materials do you have experience feeding into a dryer?

Specific Materials:

- Textiles (e.g., cotton, polyester, nylon)

- Paper products (e.g., pulp, tissue paper)

- Foodstuffs (e.g., grains, powders)

Handling Techniques:

- Scoop feeding for granular materials

- Belt feeding for continuous flow

- Vibrating feeders for delicate or sticky materials

3. How do you determine the optimal drying time for different materials?

To determine the optimal drying time, I consider the following factors:

- Material characteristics (e.g., moisture content, thickness, density)

- Desired moisture level after drying

- Dryer temperature and airflow settings

- Trial and error experimentation with small batches

- Consultation with experienced operators or technical manuals

4. What are the indicators of over- or under-drying of materials?

Over-drying:

- Brittleness

- Discoloration

- Cracking or tearing

- Reduced strength

Under-drying:

- Excessive moisture content

- Mold or mildew growth

- Compromised product quality

5. Describe your approach to maintaining and troubleshooting dryer equipment.

For maintenance, I perform the following:

- Regular cleaning and lubrication of moving parts

- Inspection of belts, bearings, and other components

- Replacement of worn or damaged parts as needed

For troubleshooting, I follow a systematic approach:

- Identify and isolate the issue

- Consult technical manuals or seek assistance from experienced technicians

- Implement appropriate repairs or adjustments

- Test the equipment to ensure proper functionality

6. What safety protocols do you observe when operating a dryer?

To ensure safety, I adhere to the following protocols:

- Wearing appropriate personal protective equipment (PPE)

- Never reaching into the dryer while it is operating

- Keeping the work area clean and free of hazards

- Following lockout/tagout procedures when performing maintenance

- Reporting any potential safety hazards or malfunctions immediately

7. How do you handle variations in material feed rates and dryer performance?

To manage variations, I:

- Adjust feed rates manually or through automated systems

- Monitor dryer temperature and airflow to optimize performance

- Make adjustments to the dryer settings as needed (e.g., speed, dwell time)

- Communicate with the production team to coordinate upstream and downstream processes

- Implement process improvements based on data analysis and feedback

8. Describe your experience with quality control measures for dried materials.

I follow these quality control procedures:

- Regular sampling of dried materials

- Testing for moisture content using moisture meters or other methods

- Visual inspection for defects or contamination

- Maintaining production records and quality control documentation

- Collaborating with the quality assurance team to ensure compliance with standards

9. How do you prioritize your tasks and manage your time effectively?

To prioritize tasks, I consider:

- Production deadlines

- Material availability

- Equipment maintenance needs

- Quality control requirements

- Safety concerns

For time management, I use the following techniques:

- Creating daily or weekly work schedules

- Breaking down large tasks into smaller ones

- Delegating tasks to other team members when possible

- Minimizing distractions and interruptions

- Seeking assistance from supervisors or colleagues when needed

10. Why are you interested in working as a Dryer Feeder for our company?

I am eager to join your company as a Dryer Feeder because:

- Your company’s reputation for quality and innovation in the industry

- The opportunity to contribute to the production of high-quality materials

- The chance to work in a team-oriented environment

- The potential for professional growth and development

- The alignment of the company’s values with my own work ethic and dedication

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dryer Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dryer Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dryer Feeders play a crucial role in ensuring the smooth operation of industrial dryers, performing various tasks to maintain production efficiency and quality.

1. Material Loading and Unloading

Dryer Feeders are responsible for loading wet material into the dryer and unloading the dried product. They operate feeders and conveyors to move material through the drying process efficiently.

2. Dryer Monitoring and Control

They monitor the dryer’s temperature, moisture content, and other operating parameters to ensure optimal drying conditions. They adjust settings and make necessary adjustments to maintain product quality and prevent equipment damage.

3. Equipment Maintenance and Inspection

Dryer Feeders perform routine maintenance tasks such as cleaning, inspecting, and lubricating equipment to prevent breakdowns and ensure smooth operation. They report any maintenance issues to supervisors for timely resolution.

4. Safety and Compliance

They adhere to safety protocols and regulations related to handling heavy materials and operating machinery. They wear appropriate safety gear and follow established procedures to minimize risks and maintain a safe work environment.

Interview Tips

To ace the job interview for a Dryer Feeder position, it’s essential to demonstrate your skills, experience, and knowledge of the industry. Here are some interview tips to help you prepare:

1. Research the Company and the Role

Thoroughly research the company and the specific role you’re applying for. This will help you understand the company’s culture, business objectives, and the key responsibilities associated with the position.

2. Highlight Your Experience and Skills

In your resume and interview, emphasize your experience in operating dryers, handling materials, and performing maintenance tasks. Showcase your proficiency in monitoring and controlling dryer operations, as well as your understanding of safety protocols.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. Practice answering these questions concisely and confidently, providing specific examples to demonstrate your abilities.

4. Prepare Industry-Specific Questions

Demonstrate your knowledge of the industry by asking thoughtful questions about the company’s drying processes, safety standards, and any recent technological advancements in dryer technology.

5. Be Enthusiastic and Professional

Show your enthusiasm for the role and the industry during the interview. Maintain a professional demeanor, participate actively in the discussion, and ask questions to indicate your interest and engagement.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Dryer Feeder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.