Are you gearing up for an interview for a Drying Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Drying Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

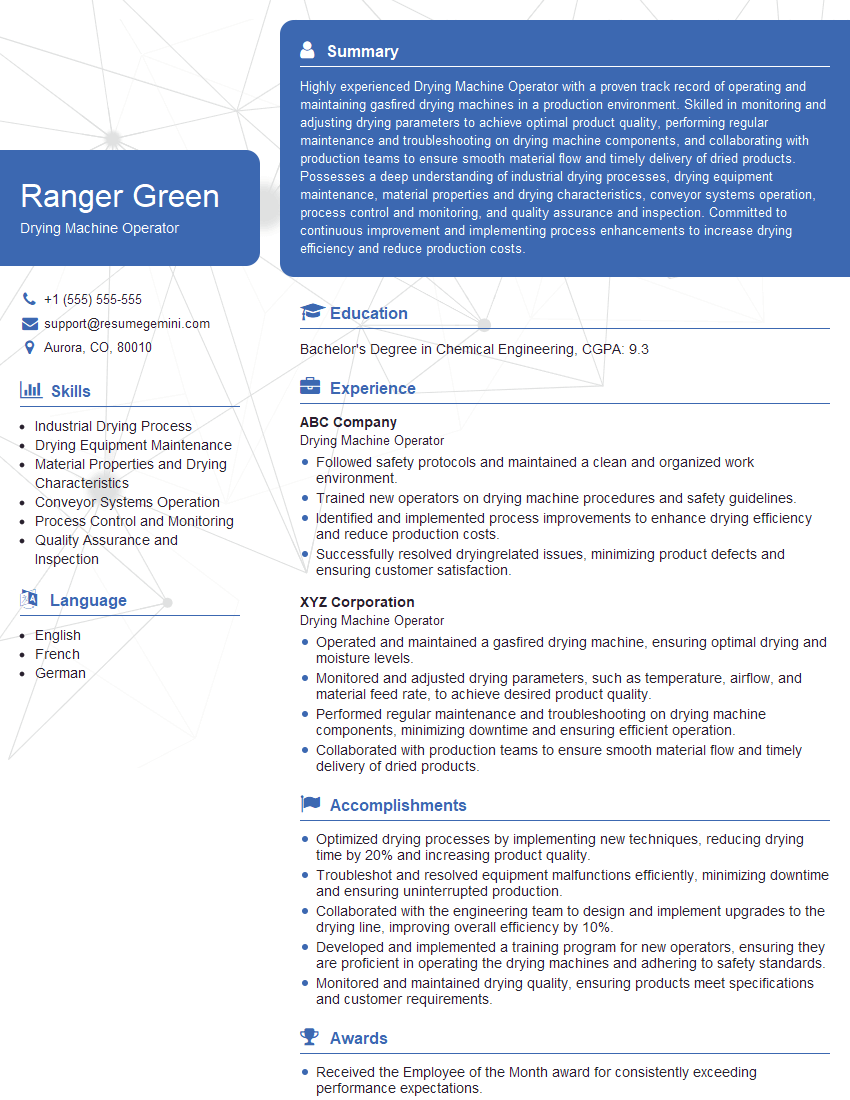

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drying Machine Operator

1. How do you ensure the efficient operation of the drying machine, maintaining optimal drying conditions and product quality?

To operate the drying machine efficiently while preserving product quality and optimal drying conditions, I adhere to the following practices:

- Regularly inspect and clean the machine components, particularly the heating elements, air filters, and conveyor belts, to prevent malfunctions and maintain optimal performance.

- Monitor and adjust the drying parameters, such as temperature, airflow, and belt speed, based on the product specifications and drying requirements to achieve the desired moisture content and prevent over-drying or under-drying.

- Conduct routine maintenance and calibration of the machine’s sensors and controls to ensure accurate readings and precise operation.

- Implement proper loading and unloading procedures to avoid damage to the product and ensure efficient flow through the machine.

2. Describe the safety protocols you follow when operating a drying machine, including emergency procedures and handling hazardous materials.

Emergency procedures

- In case of a fire, immediately activate the fire alarm and use appropriate fire extinguishers to control the flames.

- If there is an electrical fault, isolate the machine from the power source and contact a qualified electrician.

- In the event of a mechanical failure, stop the machine and isolate it from the power source to prevent further damage.

Handling hazardous materials

- When handling flammable or toxic materials, I wear appropriate personal protective equipment (PPE), including gloves, masks, and protective clothing.

- I ensure proper ventilation in the work area to prevent the accumulation of hazardous fumes or gases.

- I follow established procedures for the safe disposal of hazardous materials and contaminated waste.

3. How do you troubleshoot common problems encountered during drying operations, and what steps do you take to resolve them?

Common problems encountered during drying operations include:

- Over-drying: This can occur due to excessive temperature or prolonged drying time. I adjust the drying parameters and monitor the moisture content to prevent over-drying.

- Under-drying: Insufficient temperature or inadequate drying time can lead to under-drying. I adjust the drying parameters and extend the drying time to achieve the desired moisture content.

- Uneven drying: This can be caused by uneven airflow distribution or improper loading. I check the airflow system and adjust the loading procedure to ensure uniform drying.

- Machine malfunction: Mechanical or electrical faults can disrupt the drying process. I troubleshoot the machine, identify the problem, and take appropriate corrective actions.

4. How do you maintain accurate records of drying operations, and why is this important?

Accurate records of drying operations are crucial for several reasons:

- Quality control: Records provide evidence of the drying process and product quality, ensuring compliance with specifications and customer requirements.

- Process optimization: By analyzing drying records, I can identify areas for improvement and make adjustments to optimize the process for efficiency and product quality.

- Troubleshooting: Records help identify patterns and trends in drying operations, making it easier to troubleshoot and resolve problems.

I maintain records by:

- Recording drying parameters (temperature, airflow, belt speed, etc.) for each batch.

- Measuring and documenting the moisture content of the dried product.

- Noting any deviations from standard operating procedures.

5. Explain the different types of drying machines, and how do you select the most appropriate machine for a specific application?

There are several types of drying machines, each with its own advantages and applications:

- Conveyor dryers: Suitable for continuous drying of bulk products, such as grains, powders, and textiles.

- Rotary dryers: Ideal for drying materials with high moisture content, such as sludge, biosolids, and minerals.

- Tunnel dryers: Used for drying products that require precise temperature and airflow control, such as pharmaceuticals and electronic components.

- Vacuum dryers: Suitable for drying heat-sensitive materials or products that require a controlled atmosphere.

To select the most appropriate machine, I consider factors such as:

- Product characteristics (moisture content, physical properties, etc.)

- Drying requirements (desired moisture content, drying time, etc.)

- Production capacity and throughput

- Available space and infrastructure

6. How do you monitor and control the drying process to ensure energy efficiency and minimize environmental impact?

- Energy efficiency: I optimize machine settings to reduce energy consumption while maintaining product quality. This includes adjusting temperature, airflow, and belt speed.

- Environmental impact: I implement measures to reduce emissions and minimize waste. This may involve using renewable energy sources, recycling waste heat, and properly disposing of used materials.

7. How do you work effectively as part of a team in a production environment?

- Communication: I actively communicate with team members to coordinate tasks, share information, and resolve issues.

- Collaboration: I collaborate with colleagues to optimize processes, improve efficiency, and support each other.

- Teamwork: I am a team player who is willing to contribute my skills and support others to achieve shared goals.

8. What continuous improvement practices do you employ to enhance your skills and knowledge as a Drying Machine Operator?

- Training and development: I actively seek opportunities for training and development to enhance my technical skills and knowledge of drying principles.

- Industry best practices: I stay informed about industry best practices and technological advancements in drying technologies.

- Feedback and evaluation: I welcome feedback from supervisors and colleagues to identify areas for improvement and enhance my performance.

9. How do you handle challenging situations where production targets need to be met while maintaining quality standards?

- Prioritization: I prioritize tasks based on urgency and importance to ensure timely completion of critical tasks without compromising quality.

- Communication: I communicate with supervisors and team members to discuss challenges and seek support or alternative solutions.

- Problem-solving: I analyze problems, identify root causes, and develop innovative solutions to overcome challenges.

10. What motivated you to pursue a career as a Drying Machine Operator, and what do you find most rewarding about this profession?

I am passionate about manufacturing and the role that drying processes play in preserving and enhancing the quality of products. I find immense satisfaction in operating drying machines efficiently, ensuring the consistent production of high-quality products, and contributing to the overall success of the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drying Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drying Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drying Machine Operators are responsible for operating and maintaining drying equipment to remove moisture from products. They ensure that the drying process meets specifications and that the equipment is functioning properly.

1. Operate Drying Equipment

Drying Machine Operators operate a variety of drying equipment, including ovens, kilns, and dryers. They set up the equipment according to specifications and monitor the drying process to ensure that the product is dried to the desired moisture content.

- Set up and operate drying equipment according to specifications

- Monitor drying process to ensure that product is dried to desired moisture content

- Adjust equipment settings as needed to maintain optimal drying conditions

2. Maintain Drying Equipment

Drying Machine Operators are also responsible for maintaining the drying equipment. They perform routine maintenance tasks, such as cleaning and lubricating the equipment, and they also troubleshoot and repair any problems that may occur.

- Perform routine maintenance tasks, such as cleaning and lubricating equipment

- Troubleshoot and repair equipment problems

- Maintain a clean and organized work area

3. Ensure Product Quality

Drying Machine Operators are responsible for ensuring that the products that are dried meet the desired quality standards. They inspect the products before and after the drying process to ensure that they are free of defects and that they meet the required specifications.

- Inspect products before and after drying process

- Identify and reject defective products

- Maintain records of drying process and product quality

4. Safety and Compliance

Drying Machine Operators must follow all safety procedures and comply with all applicable regulations. They wear personal protective equipment and follow lockout/tagout procedures to prevent accidents.

- Follow all safety procedures and comply with all applicable regulations

- Wear personal protective equipment

- Follow lockout/tagout procedures

Interview Tips

To ace your interview for a Drying Machine Operator position, follow these tips:

1. Research the Company and Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company

2. Prepare Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice answering common interview questions

- Tailor your answers to the specific job you are applying for

- Be prepared to talk about your experience and skills

3. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally for your interview. Also, be sure to arrive on time. Punctuality shows that you are respectful of the interviewer’s time.

- Dress professionally

- Arrive on time

- Be polite and respectful

4. Be Yourself and Enthusiastic

The interviewer wants to get to know the real you, so be yourself and let your personality shine through. Also, show some enthusiasm for the position and the company. This will help you stand out from other candidates.

- Be yourself

- Show enthusiasm for the position and the company

- Be positive and upbeat

5. Ask Questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the position and the company. Ask thoughtful questions that show you are interested and engaged.

- Ask thoughtful questions

- Show that you are interested and engaged

- Thank the interviewer for their time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drying Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.