Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Drying Room Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Drying Room Operator so you can tailor your answers to impress potential employers.

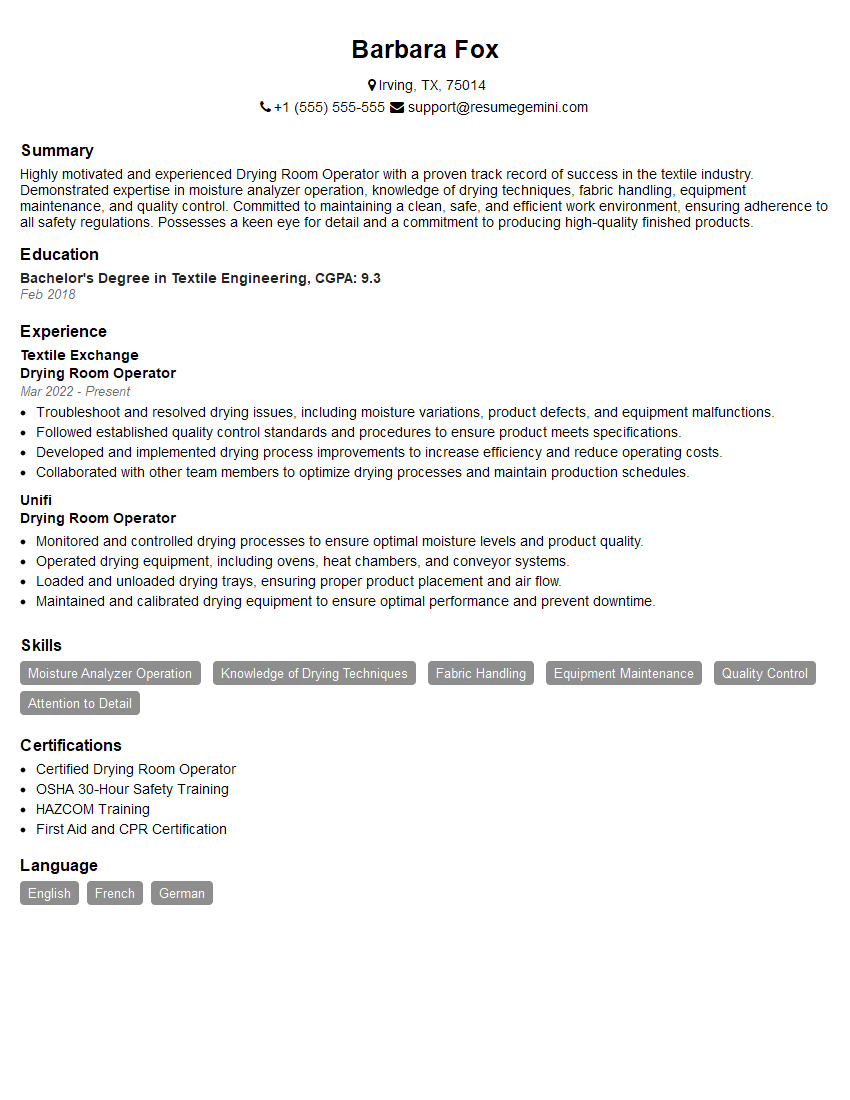

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drying Room Operator

1. What are the key principles of drying fabrics in a drying room?

The key principles of drying fabrics in a drying room involve controlling the following factors:

- Temperature: Maintaining an optimal temperature range to effectively evaporate moisture from the fabrics without damaging them.

- Humidity: Balancing humidity levels to prevent over-drying or under-drying, ensuring proper moisture content in the fabrics.

- Airflow: Ensuring adequate airflow to circulate hot air throughout the drying room, promoting efficient evaporation and preventing condensation.

2. Describe the different types of drying machines used in the textile industry and explain their advantages and disadvantages.

Batch Drying Machines

- Advantages: Flexible loading and unloading, suitable for small batches, can handle delicate fabrics.

- Disadvantages: Slow drying process, higher energy consumption.

Continuous Drying Machines

- Advantages: High drying capacity, energy-efficient, automated operation.

- Disadvantages: Not suitable for small batches, may cause fabric distortion.

Tumble Dryers

- Advantages: Fast drying times, suitable for small batches.

- Disadvantages: Can create wrinkles or fabric damage, not suitable for delicate fabrics.

3. What are the critical parameters to monitor during the drying process to ensure optimal fabric quality?

- Fabric moisture content: Continuously monitoring moisture levels to prevent under-drying (damp fabrics) or over-drying (brittle fabrics).

- Drying temperature: Maintaining the correct temperature to avoid fabric damage due to excessive heat or insufficient drying.

- Drying time: Controlling the drying duration to ensure complete removal of moisture without compromising fabric quality.

4. How do you handle situations where fabrics exhibit different drying characteristics, such as uneven drying or shrinkage?

- Identify the root cause: Determine if the issue is related to fabric type, machine settings, or environmental factors.

- Adjust drying parameters: Modify temperature, humidity, or airflow to compensate for different drying behaviors.

- Use specialized equipment: Employ tension rollers or clamps to prevent fabric shrinkage or distortion.

5. What troubleshooting steps would you take if the drying room is experiencing moisture buildup or condensation?

- Increase ventilation: Enhance airflow to remove moisture from the drying room by opening windows or using exhaust fans.

- Lower the drying temperature: Reduce the temperature to slow down the evaporation rate and allow moisture to escape.

- Check the humidity sensor: Ensure the sensor is calibrated correctly and providing accurate humidity readings.

6. How do you ensure that the drying room environment is clean and free from contaminants that could affect fabric quality?

- Regular cleaning and maintenance: Establish a cleaning schedule to remove dust, debris, and lint from the drying room and equipment.

- Use filtered air: Install air filters to prevent airborne particles from entering the drying room and contaminating fabrics.

- Control humidity: Maintain appropriate humidity levels to prevent mold or mildew growth.

7. What safety precautions should be taken when operating drying machinery and handling fabrics in the drying room?

- Wear appropriate personal protective equipment (PPE): Gloves, safety glasses, and protective clothing to prevent burns or injuries.

- Follow machine operating instructions: Adhere to manufacturer guidelines for safe operation and maintenance of drying equipment.

- Handle fabrics carefully: Avoid touching hot fabrics or moving heavy loads without assistance.

8. How do you handle situations where fabrics have sensitive finishes or require special drying conditions?

- Consult with the fabric supplier or manufacturer: Obtain specific drying instructions to avoid damaging delicate finishes.

- Use specialized drying techniques: Employ low-temperature drying, controlled humidity, or vacuum drying methods as necessary.

- Monitor closely: Pay extra attention to moisture content and fabric appearance to ensure optimal results.

9. What record-keeping practices do you follow to document drying process data and ensure quality control?

- Maintain production logs: Record machine settings, drying parameters, and fabric characteristics for each production run.

- Use quality control charts: Track moisture content and drying time data to identify trends and potential issues.

- Generate reports: Create regular reports summarizing drying performance, fabric quality, and any deviations from standard procedures.

10. How do you stay up-to-date with the latest advancements in drying technology and best practices?

- Attend industry conferences and workshops: Participate in events to learn about new technologies, research findings, and industry trends.

- Read industry publications: Stay informed by subscribing to trade magazines and journals that cover drying techniques and equipment.

- Consult with equipment manufacturers: Engage with industry experts to gain insights into the latest technological developments and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drying Room Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drying Room Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Drying Room Operator plays a crucial role in ensuring the efficient and safe functioning of the drying room, contributing to the overall quality of the finished products.

1. Operating and Monitoring Drying Equipment

Maintaining the optimal operating conditions of drying equipment, including ovens, dryers, and kilns, is critical. The Drying Room Operator is responsible for adjusting temperature, humidity, and airflow parameters to meet the specific requirements of different materials and products.

- Calibrating and maintaining drying equipment to ensure accurate and consistent performance

- Monitoring drying processes to ensure that products meet specifications and quality standards

2. Loading and Unloading Products

Properly handling and placing products in and out of the drying equipment is essential for safety and efficiency. The Drying Room Operator carefully loads and unloads materials, adhering to safety protocols and using appropriate equipment.

- Using hoists, forklifts, and other equipment to transport and handle products safely

- Ensuring that products are properly positioned and spaced within the drying equipment to optimize air circulation

3. Quality Control and Inspection

Ensuring the quality of dried products is crucial. The Drying Room Operator inspects products visually and performs simple tests to check for defects, moisture content, and other quality attributes.

- Conducting visual inspections to identify any visible defects or damage

- Measuring moisture content using moisture meters or other testing methods

4. Recordkeeping and Reporting

Maintaining accurate records is essential for tracking drying processes and product quality. The Drying Room Operator documents equipment settings, product specifications, and any deviations from standard procedures.

- Maintaining logbooks to record drying conditions, product data, and any unusual observations

- Reporting any equipment malfunctions, product defects, or quality concerns promptly

Interview Tips

To ace the interview for a Drying Room Operator position, it is imperative to prepare thoroughly and showcase your skills and knowledge. Here are some tips and hacks to help you stand out:

1. Research the Company and Role

Familiarize yourself with the company’s products, industry, and culture. Learn about the specific responsibilities of the Drying Room Operator and how they align with your skills and experience.

- Visit the company’s website and social media pages for information about their products, services, and mission.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies in the drying industry.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience in operating drying equipment, handling materials, and ensuring product quality. Quantify your accomplishments whenever possible.

- Share specific examples of how you have improved drying efficiency or resolved production issues in previous roles.

- Demonstrate your knowledge of different drying methods, equipment, and their applications.

3. Prepare for Technical Questions

Be prepared to answer questions related to the technical aspects of drying processes, equipment, and quality control. Review common drying techniques and troubleshooting methods.

- Practice answering questions about how to achieve optimal drying conditions for different materials.

- Explain how to identify and resolve common drying defects, such as over-drying or under-drying.

4. Show Safety Awareness

Drying processes involve potential hazards. Emphasize your commitment to safety by highlighting your knowledge of safety protocols and your adherence to them.

- Explain how you follow standard operating procedures and ensure proper ventilation to minimize risks.

- Share examples of how you have identified and mitigated potential hazards in the drying room.

5. Be Confident and Enthusiastic

Project confidence in your abilities and enthusiasm for the role. Show that you are eager to contribute to the company’s success and have a genuine interest in drying processes.

- Prepare an engaging introduction that highlights your passion for the drying industry and your desire to make a positive impact.

- Ask thoughtful questions at the end of the interview to show your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drying Room Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!