Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Drying Tunnel Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

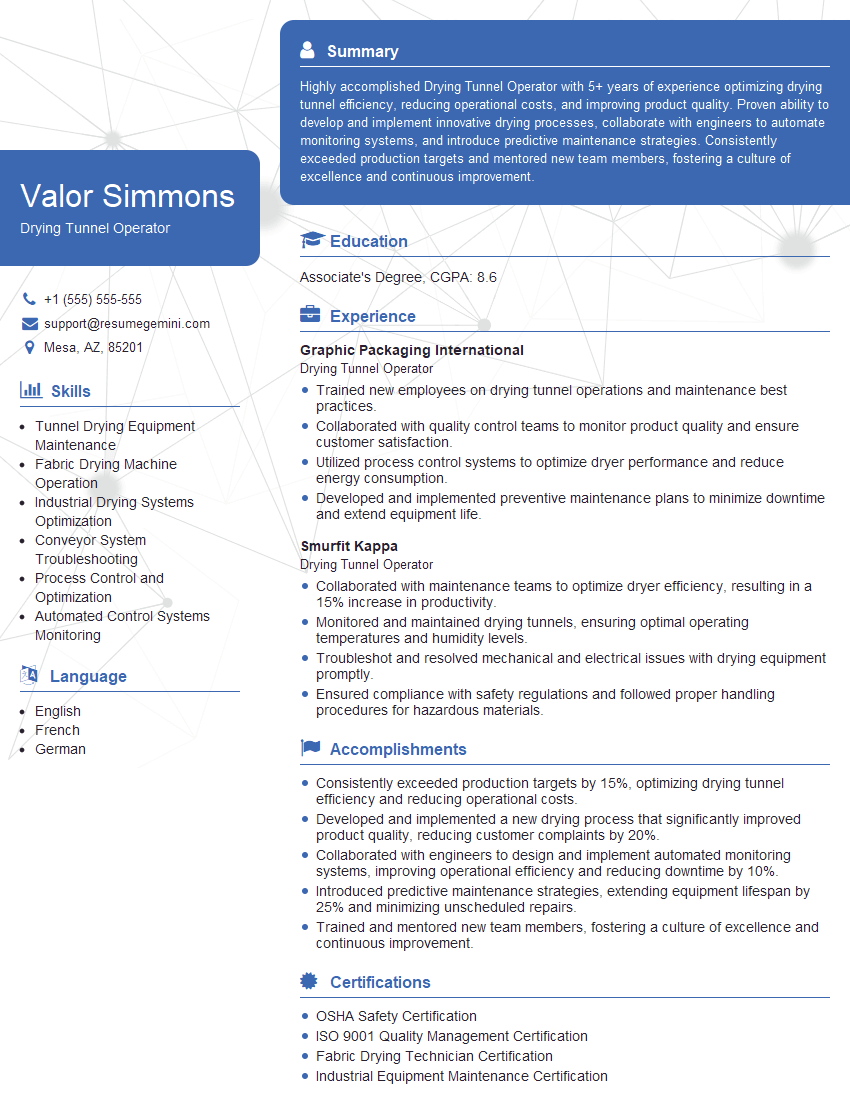

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drying Tunnel Operator

1. Explain the primary responsibilities of a Drying Tunnel Operator.

- Operate and monitor the drying tunnel to ensure products are dried to specifications

- Adjust temperature, humidity, and airflow settings to optimize drying process

- Inspect products before and after drying to ensure quality standards are met

- Maintain records of drying parameters and product quality

- Troubleshoot and resolve any issues with the drying tunnel or products

2. Describe the different types of drying tunnels and how they operate.

- Operate by loading a batch of parts, materials, or products onto a conveyor belt

- Convey the products through the tunnel, which is heated to evaporate moisture

- Operate by continuously feeding products into the tunnel on one end and discharging them on the other

- Products are typically conveyed through the tunnel on a conveyor belt or hanger system

- Operate by suspending products in a stream of hot air

- The hot air evaporates moisture from the products, and the products are discharged from the dryer

Batch drying tunnels

Continuous drying tunnels

Fluidized bed dryers

3. What are the key performance indicators (KPIs) for a Drying Tunnel Operator?

- Product quality

- Drying efficiency

- Energy consumption

- Equipment uptime

- Safety

4. How do you ensure the quality of products dried in the tunnel?

- Inspect products before and after drying to check for defects, damage, or contamination

- Monitor drying parameters (temperature, humidity, airflow) to ensure they are within specified ranges

- Calibrate and maintain drying equipment regularly to ensure accuracy and precision

- Follow established quality control procedures and adhere to industry best practices

5. How do you troubleshoot common problems with drying tunnels?

- Identify the problem by observing the products, equipment, and process parameters

- Consult with maintenance personnel or technical experts to determine the root cause

- Implement corrective actions to resolve the problem, such as adjusting drying parameters, replacing defective components, or cleaning the equipment

- Monitor the process after troubleshooting to ensure the problem has been resolved

6. What are the safety protocols and procedures for working with drying tunnels?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat

- Follow lockout/tagout procedures when servicing or repairing equipment

- Be aware of potential hazards, such as hot surfaces, moving machinery, and flammable materials

- Report any safety concerns or incidents to a supervisor immediately

- Receive training on safety protocols and emergency procedures

7. How do you optimize the drying process to improve efficiency and reduce costs?

- Monitor and adjust drying parameters (temperature, humidity, airflow) to optimize drying time and energy consumption

- Use energy-efficient equipment and technologies

- Perform regular maintenance and calibration to ensure equipment is operating at peak efficiency

- Train operators on best practices for efficient drying

8. What are the different types of products that can be dried in a drying tunnel, and how do the drying parameters vary depending on the product?

- Fruits, vegetables, meat, fish, and dairy products

- Drying parameters: temperature, humidity, airflow, and drying time vary depending on the product and desired moisture content

- Active pharmaceutical ingredients (APIs), excipients, and finished dosage forms

- Drying parameters: temperature, humidity, airflow, and drying time are strictly controlled to ensure product quality and stability

- Pigments, dyes, and other chemical compounds

- Drying parameters: temperature, humidity, airflow, and drying time are tailored to the specific chemical properties of the product

- Textiles, paper, and plastics

- Drying parameters: temperature, humidity, airflow, and drying time are adjusted to achieve desired moisture content and properties

Food products

Pharmaceuticals

Chemicals

Industrial materials

9. How do you ensure that the drying tunnel is operating in compliance with environmental regulations?

- Monitor and control emissions to meet air quality standards

- Use energy-efficient equipment and technologies to reduce greenhouse gas emissions

- Dispose of wastewater and other waste products in accordance with environmental regulations

- Maintain records of environmental monitoring and compliance activities

10. Describe a challenging situation you faced as a Drying Tunnel Operator, and how you overcame it.

- A critical drying tunnel malfunctioned during a production run, threatening to delay product delivery

- Quickly diagnosed the problem and identified a faulty sensor

- Replaced the sensor and recalibrated the equipment, restoring the drying tunnel to operation within a minimal amount of downtime

- Collaborated with maintenance personnel to ensure the sensor was functioning correctly and prevented future malfunctions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drying Tunnel Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drying Tunnel Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drying Tunnel Operators play a crucial role in ensuring the smooth and efficient operation of drying tunnels in various industries. Their key responsibilities include:

1. Loading and Unloading Products

Loading and unloading products into and out of the drying tunnel, ensuring proper placement and adherence to safety protocols.

- Manually or using automated systems to load products onto conveyors.

- Monitoring product flow and adjusting loading/unloading rates to maintain optimal production.

- Ensuring proper product spacing and orientation to prevent damage during processing.

2. Monitoring Tunnel Conditions

Continuously monitoring and adjusting temperature, humidity, airflow, and other tunnel conditions to meet product specifications.

- Calibrating and maintaining instrumentation to ensure accurate readings.

- Adjusting fan speed, heater settings, and dampers to optimize drying performance.

- Identifying and troubleshooting any deviations from set parameters to minimize downtime.

3. Inspecting Products

Inspecting products post-drying for quality, consistency, and adherence to specifications.

- Visually examining products for defects, discolorations, or other anomalies.

- Measuring moisture content using appropriate equipment to ensure compliance with standards.

- Rejecting or rerouting products that do not meet specifications.

4. Equipment Maintenance

Performing routine maintenance and cleaning of the drying tunnel and related equipment.

- Cleaning conveyors, filters, and other components to ensure efficient operation.

- Lubricating moving parts and conducting minor repairs as needed.

- Reporting any major issues or equipment failures to supervisors.

Interview Tips

Preparing thoroughly can significantly increase your chances of success in a Drying Tunnel Operator interview. Here are some crucial tips:

1. Research the Company and Industry

Learn about the company’s history, products, and market position. Research industry trends and best practices to demonstrate your understanding of the sector.

- Visit the company website and read industry publications.

- Attend industry events or webinars to gain insights.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience in loading/unloading operations, equipment maintenance, and quality control. Showcase your understanding of drying processes and your ability to troubleshoot issues.

- Quantify your accomplishments using specific metrics whenever possible.

- Provide examples of how you improved efficiency or resolved problems in previous roles.

3. Demonstrate Safety Awareness

Stress your commitment to safety and your knowledge of relevant regulations. Explain how you ensure the proper handling and storage of materials and follow established safety procedures.

- Describe your experience with personal protective equipment (PPE) and emergency procedures.

- Highlight any safety certifications or training you have received.

4. Show Enthusiasm and Eagerness

Express your passion for the industry and your desire to contribute to the company’s success. Demonstrate your willingness to learn and take on new challenges.

- Share your reasons for applying to the position and how it aligns with your career goals.

- Ask thoughtful questions to show your engagement and interest in the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Drying Tunnel Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Drying Tunnel Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.