Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Duco Polisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

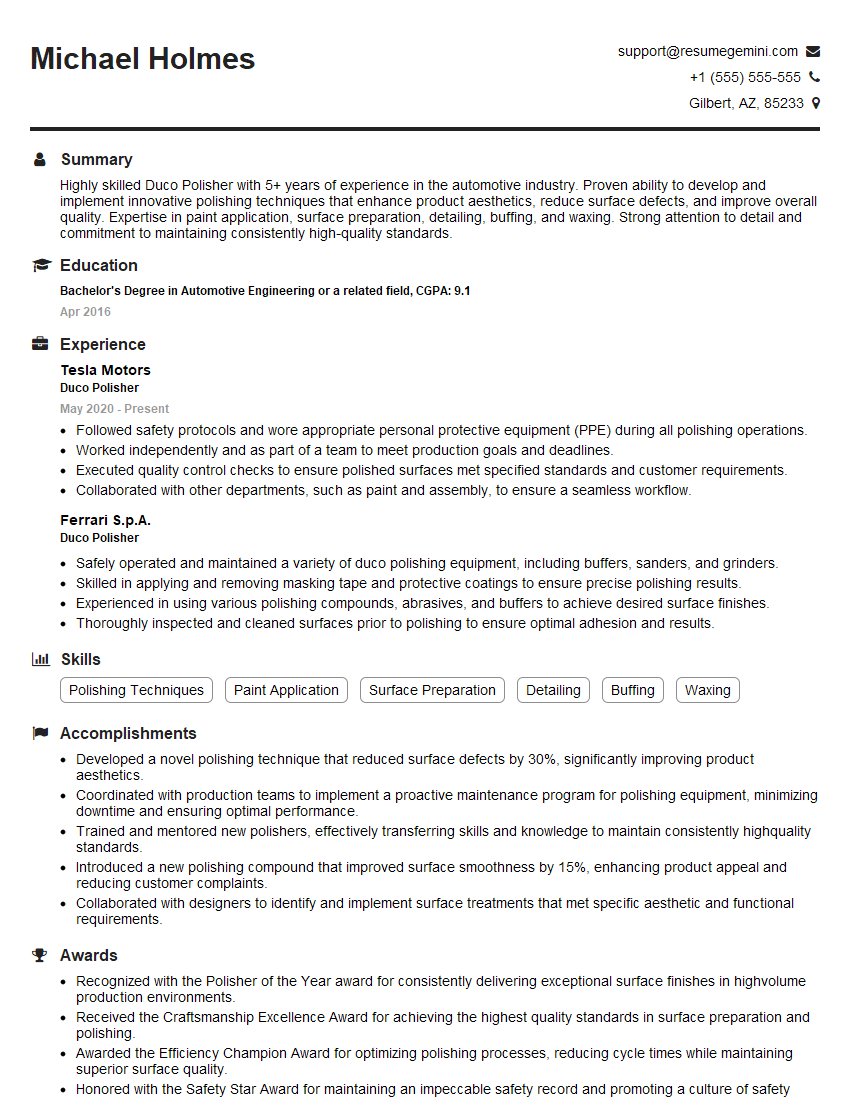

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Duco Polisher

1. How do you determine the right polishing technique for different types of paint?

I first assess the condition of the paint, including its age, type, and level of damage. Based on this assessment, I select the appropriate polishing technique and materials. For example, I would use a less abrasive technique for newer paint, while I would use a more aggressive technique for heavily oxidized paint.

2. What are the common mistakes to avoid when polishing duco?

Mistakes to Avoid

- Using the wrong polishing technique or materials for the paint type

- Applying too much pressure or using a high-speed polisher

- Not using a clean polishing pad or cloth

- Not removing the polishing compound residue properly

Consequences

- Damage to the paint, such as scratches or swirls

- Uneven finish

- Holograming

3. How do you achieve a high-gloss finish without damaging the paint?

To achieve a high-gloss finish without damaging the paint, I follow these steps:

- Use a high-quality polishing compound and a clean polishing pad.

- Apply the polishing compound to the pad and spread it evenly over the surface.

- Use a low-speed polisher and apply gentle pressure.

- Move the polisher in circular or overlapping motions.

- Remove the polishing compound residue with a clean microfiber cloth.

- Repeat the process as necessary until the desired gloss level is achieved.

4. How do you handle deep scratches or swirl marks?

To handle deep scratches or swirl marks, I use a combination of techniques:

- For deep scratches, I use wet sanding with progressively finer grades of sandpaper to remove the damaged paint.

- For swirl marks, I use a polishing compound with a mild abrasive to remove the imperfections.

- After sanding or polishing, I apply a finishing glaze to enhance the gloss and protect the paint.

5. What are the different types of polishing pads and when to use each one?

There are several types of polishing pads, each designed for a specific purpose:

- Wool pads: Used for aggressive polishing and removing deep scratches

- Foam pads: Used for polishing and finishing, available in different densities and firmness levels

- Microfiber pads: Used for light polishing and finishing, gentle on the paint

- Hybrid pads: Combine different materials, such as wool and foam, for versatility

I select the appropriate pad based on the condition of the paint and the desired finish.

6. How do you maintain your polishing equipment?

To maintain my polishing equipment, I follow a regular cleaning and maintenance schedule:

- After each use, I clean the polishing pads thoroughly with soap and water.

- I inspect the polishing pads regularly for wear and tear, and replace them when necessary.

- I clean the polisher body and other components with a damp cloth to remove dust and dirt.

- I lubricate the polisher according to the manufacturer’s instructions.

7. What are the safety precautions you take when polishing duco?

When polishing duco, I take the following safety precautions:

- Wear appropriate safety gear, including safety glasses, gloves, and a respirator.

- Ensure the work area is well-ventilated to minimize exposure to dust and fumes.

- Keep the polishing machine away from flammable materials and liquids.

- Never leave the polisher unattended while it is running.

8. How do you estimate the cost of a polishing job?

To estimate the cost of a polishing job, I consider the following factors:

- Size and condition of the vehicle

- Type of paint and finish desired

- Amount of labor required

- Cost of materials

I provide a detailed estimate to the customer before starting the job.

9. What is the difference between polishing and waxing?

Polishing and waxing are both processes that improve the appearance of a vehicle’s paint, but they serve different purposes:

- Polishing removes imperfections from the paint surface, such as scratches, swirl marks, and oxidation.

- Waxing applies a protective layer to the paint, which helps to protect it from the elements and enhance its shine.

Polishing is typically done less frequently than waxing, as it is a more abrasive process.

10. How do you stay up-to-date with the latest techniques and products in the duco polishing industry?

I stay up-to-date with the latest techniques and products in the duco polishing industry through the following channels:

- Attending industry trade shows and conferences

- Reading trade publications and online forums

- Consulting with manufacturers and distributors

- Experimenting with new products and techniques

By staying current, I can offer my customers the best possible service and results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Duco Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Duco Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Duco Polishers are responsible for preparing and polishing surfaces to a high standard, ensuring they are smooth and free of defects. Key responsibilities include:

1. Surface Preparation

Preparing and cleaning surfaces before polishing, removing any rust, dirt, or other contaminants.

- Sanding and smoothing surfaces using sandpaper or grinding wheels.

- Cleaning and degreasing surfaces with solvents or other cleaning agents.

2. Polishing

Polishing surfaces using a variety of techniques and equipment, including:

- Using polishing wheels or buffs to apply polishes and compounds.

- Hand-polishing using cloths or pads to achieve a desired finish.

- Operating automated polishing machines to polish large or complex surfaces.

3. Quality Control

Inspecting and checking the quality of polished surfaces to ensure they meet specifications and standards.

- Using measuring instruments and gauges to verify dimensions and tolerances.

- Visually inspecting surfaces for defects, scratches, or other imperfections.

4. Maintenance

Maintaining and cleaning polishing equipment and tools to ensure optimal performance and safety.

- Cleaning and lubricating polishing wheels, buffs, and other equipment.

- Inspecting and replacing worn or damaged equipment components.

Interview Preparation Tips

To prepare for a Duco Polisher interview, the following tips can help you present your skills and experience effectively:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry, as well as the specific requirements for the Duco Polisher position.

- Visit the company’s website and social media profiles.

- Read industry publications and articles to stay updated on trends and best practices.

2. Highlight Your Skills and Experience

Emphasize your proficiency in surface preparation, polishing techniques, and quality control. Quantify your accomplishments whenever possible, using specific metrics and examples.

- Describe projects where you successfully polished surfaces to a high standard, meeting or exceeding specifications.

- Mention any specialized polishing techniques or equipment you have experience with.

3. Demonstrate Your Attention to Detail

Duco Polishers must have a keen eye for detail and accuracy. Provide examples of your meticulous work and ability to meet precise requirements.

- Discuss your experience using measuring instruments and gauges to ensure dimensional accuracy.

- Explain how you inspect surfaces for defects and take corrective measures.

4. Show Your Commitment to Safety

Safety is a critical aspect of polishing work. Emphasize your understanding of safety procedures and your commitment to working safely.

- Describe your experience with proper handling and storage of polishing materials.

- Explain your familiarity with the use of personal protective equipment (PPE).

5. Practice Your Answers

Prepare answers to common interview questions and rehearse them in advance. This will help you feel confident and articulate during the interview.

- Consider questions related to your polishing experience, attention to detail, and safety practices.

- Practice answering questions using the STAR method (Situation, Task, Action, Result).

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Duco Polisher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.