Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Duct Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

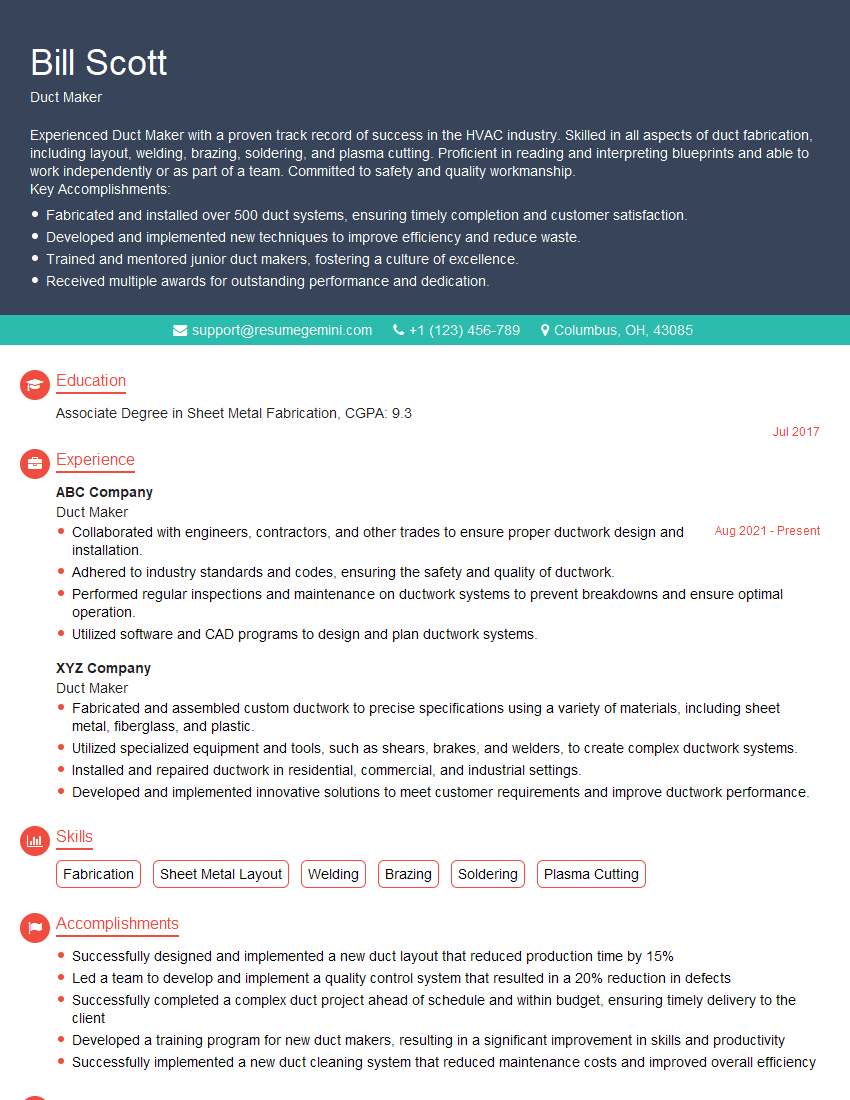

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Duct Maker

1. Describe the process of duct fabrication, including the tools and materials used?

The duct fabrication process involves several steps to create custom ducts for HVAC systems. The process typically includes:

- Design and Layout: Using specifications and measurements, the duct layout is designed, considering factors like airflow requirements, space constraints, and efficiency.

- Material Selection: Based on the project requirements, the appropriate duct material is selected, such as galvanized steel, aluminum, or fiberglass.

- Cutting and Forming: The sheet metal is cut to the desired shape and size using tools like shears, nibblers, or plasma cutters. Bending and forming machines are used to create the required angles and shapes.

- Joining and Assembly: The duct components are joined together using methods like welding, riveting, or seaming. Sealants and gaskets are used to ensure airtight connections.

- Testing and Inspection: The fabricated ducts undergo rigorous testing to ensure they meet the specified requirements for airflow, pressure, and leakage.

2. What are the different types of duct joints used in duct fabrication, and when is each type preferred?

- Slip Joint: This is a simple joint where one duct slides into another, providing flexibility and ease of assembly. It’s commonly used in low-pressure applications.

- Pittsburgh Lock: This joint creates a mechanically interlocked seam, making it strong and airtight. It’s suitable for higher-pressure applications and is often used in commercial and industrial settings.

- Drive Cleat Joint: This joint involves interlocking cleats that are driven together, creating a tight and durable connection. It’s commonly used in larger duct systems and provides structural integrity.

- Flanged Joint: This joint uses flanges that are bolted together to connect duct sections. It allows for easy disassembly and is often used in demanding applications or where access is required.

- Welded Joint: This permanent joint involves welding the duct components together. It provides the strongest and most airtight connection, but it requires specialized equipment and skilled fabricators.

3. How do you calculate the airflow capacity of a duct system?

- Determine the Required Airflow Rate: Use the building’s volume, occupancy, and ventilation standards to calculate the required airflow in cubic feet per minute (CFM).

- Calculate Duct Velocity: Select an appropriate duct velocity based on factors like noise level, pressure drop, and energy efficiency. Common velocities range from 500 to 1500 feet per minute (FPM).

- Determine Duct Cross-sectional Area: Divide the airflow rate by the duct velocity to calculate the required cross-sectional area of the duct in square feet.

- Select Duct Size: Choose the standard duct size that provides the closest match to the calculated cross-sectional area.

4. What factors influence the pressure drop in a duct system?

- Duct Length: Longer ducts result in higher friction losses and increased pressure drop.

- Duct Diameter: Smaller ducts have higher friction factors, leading to greater pressure drop.

- Airflow Velocity: Higher airflow velocities result in increased friction and turbulence, causing higher pressure drop.

- Duct Fittings and Transitions: Bends, elbows, and transitions create turbulence and resistance to airflow, contributing to pressure drop.

- Duct Material: Smooth materials like galvanized steel have lower friction factors compared to rougher materials.

5. How do you ensure the airtightness of a duct system?

- Proper Joint Fabrication: Use appropriate joint types and techniques to create airtight connections.

- Sealants and Gaskets: Apply sealants and gaskets at joints to prevent air leakage.

- Testing and Inspection: Conduct thorough testing using smoke generators or other methods to identify and seal any leaks.

- Regular Maintenance: Inspect and maintain the duct system regularly to ensure continued airtightness.

6. What safety precautions should be observed during duct fabrication and installation?

- Wear Appropriate PPE: Use gloves, safety glasses, and respirators to protect against metal shavings, dust, and fumes.

- Handle Materials Safely: Sharp sheet metal edges can cause cuts, so handle materials with care.

- Ventilate Work Area: Ensure adequate ventilation to remove fumes and dust.

- Avoid Electrical Hazards: Be cautious of electrical wires and equipment, especially when using power tools.

- Follow Lockout/Tagout Procedures: Isolate equipment before performing maintenance or repairs.

7. How do you stay updated with the latest advancements and best practices in duct fabrication?

- Attend Industry Events: Participate in conferences, workshops, and trade shows related to duct fabrication.

- Read Trade Publications: Keep up-to-date with industry news, technical articles, and product developments.

- Obtain Certifications: Seek certifications from reputable organizations to demonstrate proficiency in duct fabrication techniques.

- Network with Professionals: Engage with other duct fabricators, engineers, and contractors to exchange knowledge and ideas.

- Stay Informed about Codes and Standards: Familiarize yourself with the latest building codes and industry standards related to duct fabrication.

8. Describe your experience in working with different types of duct materials, such as galvanized steel, aluminum, and fiberglass.

- Galvanized Steel: I have extensive experience working with galvanized steel, which is commonly used in duct fabrication due to its durability, affordability, and corrosion resistance.

- Aluminum: I am proficient in handling aluminum, which offers lightweight, corrosion-resistant, and non-magnetic properties, making it suitable for specialized applications like cleanrooms and food processing facilities.

- Fiberglass: I have worked with fiberglass, a composite material known for its insulation properties and resistance to chemicals and moisture. It is commonly used in applications requiring thermal or acoustic insulation.

9. How do you handle deviations from specifications or unexpected challenges during a duct fabrication project?

- Communicate with Client: I promptly inform the client of any discrepancies or challenges encountered.

- Explore Alternative Solutions: I brainstorm and research alternative solutions that meet the client’s needs and adhere to industry standards.

- Document Changes: I meticulously document any deviations from the original specifications and obtain necessary approvals.

- Maintain Transparency: Throughout the process, I keep the client updated on progress and any adjustments made to ensure their satisfaction.

10. What sets you apart as an exceptional Duct Maker?

- Technical Expertise: I possess a deep understanding of duct fabrication techniques, materials, and industry standards.

- Attention to Detail: I am meticulous in my work, ensuring accuracy and precision in every aspect of duct fabrication.

- Problem-Solving Skills: I am adept at identifying and resolving challenges, finding innovative solutions to meet project requirements.

- Strong Communication: I effectively communicate with clients, colleagues, and supervisors, fostering productive working relationships.

- Commitment to Quality: I am passionate about delivering high-quality duct systems that meet or exceed client expectations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Duct Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Duct Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Duct makers are responsible for fabricating and installing air ducts in residential, commercial, and industrial buildings. They also perform maintenance and repairs on existing ductwork. Some of the key job responsibilities include:

1. Fabricate and install air ducts

Duct makers use a variety of materials to fabricate air ducts, including sheet metal, fiberglass, and plastic. They cut, shape, and assemble duct sections using specialized tools and equipment. They also install ductwork in buildings, following blueprints and specifications.

2. Maintain and repair ductwork

Duct makers perform regular maintenance on ductwork to ensure efficient airflow and prevent problems. They may also repair damaged or leaking ducts. They use a variety of tools and techniques to perform maintenance and repairs, including vacuum cleaners, brushes, and sealants.

3. Inspect ductwork

Duct makers inspect ductwork to identify problems and ensure that it is operating safely and efficiently. They use a variety of tools and techniques to inspect ductwork, including cameras, mirrors, and flashlights. They also check for leaks, blockages, and other problems.

4. Liaise with other trades

Duct makers often work with other trades, such as electricians, plumbers, and HVAC technicians. They coordinate their work with other trades to ensure that ductwork is installed properly and meets all codes and regulations.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to improve your chances of success. Here are a few interview tips and hacks to help you ace your interview for a Duct Maker position:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. You can also learn more about the specific requirements of the position.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver clear and concise responses.

3. Be prepared to talk about your experience

The interviewer will likely ask you about your experience in duct fabrication and installation. Be prepared to talk about your skills and experience, and how they relate to the requirements of the position.

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

5. Dress professionally

First impressions matter, so dress professionally for your interview. This means wearing a suit or dress pants and a button-down shirt. You should also make sure that your clothes are clean and pressed.

Next Step:

Now that you’re armed with the knowledge of Duct Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Duct Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini