Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dump Motor Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dump Motor Operator so you can tailor your answers to impress potential employers.

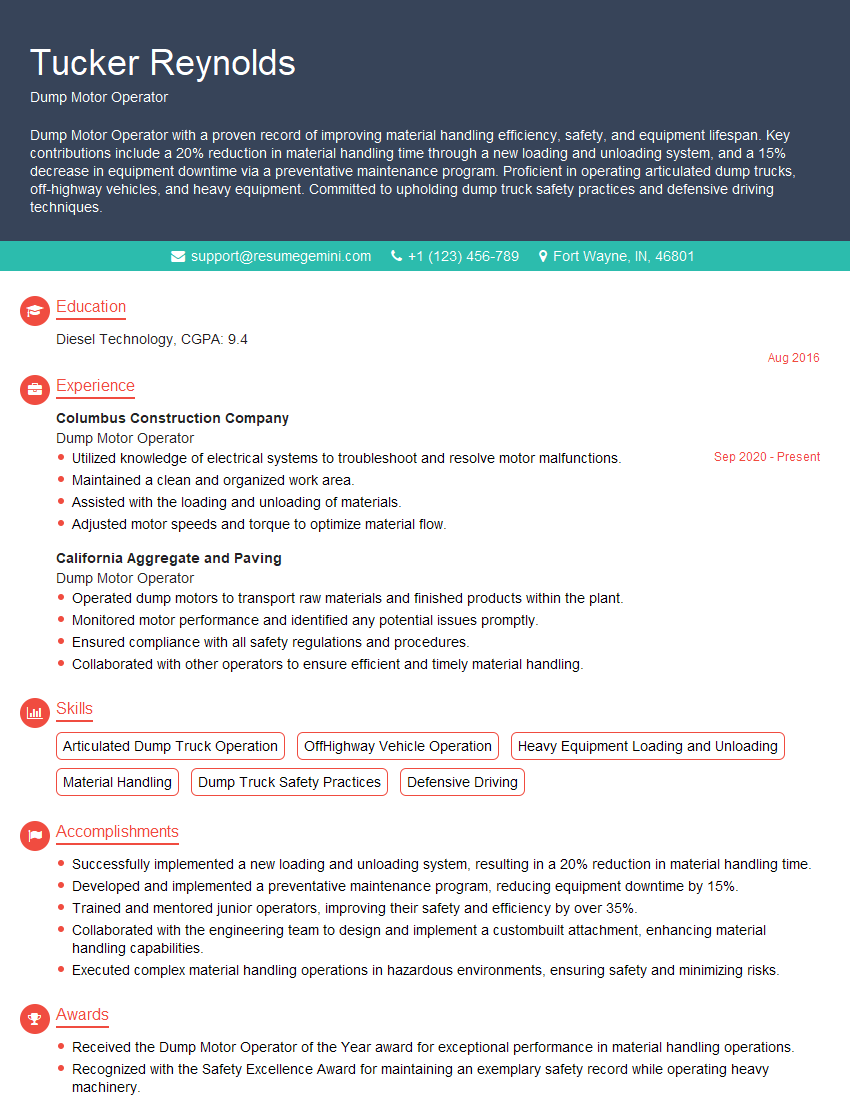

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dump Motor Operator

1. Explain the process of daily inspections and pre-operational checks you perform before operating a dump motor?

- Inspect the vehicle for any damage or leaks and ensure all lights and signals are functioning correctly.

- Check fluid levels, including oil, coolant, and hydraulic fluid, and top up if necessary.

- Test the dump bed’s operation and ensure it is moving smoothly and securely.

- Inspect the tires for proper inflation and any signs of wear or damage.

- Conduct a thorough visual inspection of the undercarriage, drive shafts, and boom for any loose bolts or damage.

2. Describe the safety precautions and protocols you follow when operating a dump motor in different work environments?

subheading of the answer

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, and high-visibility clothing.

- Maintain a safe distance from other vehicles and personnel.

- Inspect the work area for overhead hazards and ensure there is adequate clearance for the dump bed.

- Use hand signals or radios to communicate with coworkers and ensure everyone is aware of the vehicle’s movements.

- Be aware of the vehicle’s blind spots and take extra precautions when reversing or turning.

subheading of the answer

- In confined spaces, ensure proper ventilation and be mindful of restricted visibility.

- When working on slopes, maintain a stable position and use the dump motor’s brakes effectively.

- In wet or icy conditions, adjust driving speed and exercise caution to prevent slipping or skidding.

3. How do you handle and maneuver a dump motor in tight or confined workspaces?

- Plan the dump motor’s movements carefully, considering the available space and the obstacles present.

- Use pivot turns or three-point turns to maneuver the vehicle in tight corners or narrow spaces.

- Reverse the dump motor slowly and carefully, using mirrors or a spotter for guidance.

- Coordinate with other workers to ensure a clear path and avoid collisions.

- Utilize the dump motor’s hydraulic stabilizers to provide stability when working on uneven or sloping surfaces.

4. What maintenance and troubleshooting procedures do you perform to ensure the dump motor is operating optimally?

- Regularly clean and lubricate all moving parts, including the dump bed, hydraulic cylinders, and drive train.

- Inspect and replace filters, such as air filters, fuel filters, and hydraulic filters, as per the manufacturer’s recommendations.

- Monitor fluid levels and top up or change fluids as necessary.

- Identify and repair any leaks or damage promptly to prevent further issues.

- Troubleshoot common problems, such as hydraulic system malfunctions, electrical issues, or engine performance problems, and take appropriate corrective actions.

5. How do you prioritize safety and prevent accidents when operating a dump motor?

- Always conduct thorough pre-operational checks and address any issues before operating the dump motor.

- Wear appropriate PPE and ensure that coworkers and bystanders are aware of the vehicle’s movements.

- Maintain a safe distance from other vehicles and personnel, especially when reversing or turning.

- Be aware of the dump motor’s blind spots and take extra precautions when working in confined spaces or around obstacles.

- Never operate the dump motor under the influence of alcohol or drugs, and report any unsafe conditions or behavior promptly.

6. How do you respond to and manage emergencies or unexpected situations while operating a dump motor?

- Remain calm and assess the situation quickly to determine the appropriate course of action.

- If there is an immediate danger, evacuate the dump motor and move to a safe location.

- Contact emergency services if necessary and provide clear information about the situation.

- Protect the dump motor and property by taking steps to prevent further damage or loss.

- Report the incident to your supervisor or manager and cooperate fully with any investigations.

7. How do you work effectively as part of a team and coordinate with other operators or workers on job sites?

- Communicate clearly and effectively with other team members using hand signals, radios, or other methods.

- Cooperate and assist other operators in completing tasks safely and efficiently.

- Share information about site conditions, hazards, or potential delays to ensure everyone is aware and prepared.

- Follow instructions from supervisors or lead operators and work together to achieve project goals.

- Maintain a positive and professional attitude, even in challenging or stressful situations.

8. What is your understanding of the regulations and standards governing the operation of dump motors in your jurisdiction?

- Be familiar with and adhere to all applicable regulations, including those related to vehicle safety, load limits, and operating procedures.

- Hold the necessary licenses or certifications required for dump motor operation in the jurisdiction.

- Understand the importance of following industry best practices and manufacturer guidelines to ensure safe and efficient operation.

- Stay informed about any changes or updates to relevant regulations and standards.

- Report any violations or non-compliance to supervisors or appropriate authorities.

9. What techniques do you use to conserve fuel and minimize environmental impact while operating a dump motor?

- Plan efficient routes and minimize unnecessary idling to reduce fuel consumption.

- Avoid overloading the dump motor and distribute the load evenly to prevent excessive fuel usage.

- Maintain proper tire pressure and perform regular maintenance to ensure optimal fuel efficiency.

- Use eco-friendly driving techniques, such as smooth acceleration and gradual braking.

- Monitor fuel consumption and identify areas where improvements can be made.

10. How do you stay up-to-date with advancements in dump motor technology and best practices?

- Attend industry workshops, conferences, or training programs to learn about new technologies and techniques.

- Read trade publications, technical manuals, and online resources to stay informed about industry developments.

- Network with other dump motor operators and share knowledge and experiences.

- Seek opportunities to participate in pilot programs or trials of new dump motor technologies.

- Provide feedback to manufacturers or suppliers on areas for improvement and innovation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dump Motor Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dump Motor Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Dump Motor Operator

A Dump Motor Operator is a construction worker who operates heavy machinery to move materials and debris. They play a vital role in construction projects, ensuring efficient and safe transportation of materials.

1. Operating Dump Trucks

The primary responsibility of a Dump Motor Operator is to operate dump trucks. They drive the trucks to transport materials such as soil, gravel, sand, and construction debris from one location to another.

- Loading materials into the truck using equipment such as front-end loaders or excavators.

- Driving the truck to designated loading and unloading zones.

- Dumping the materials at the designated areas.

2. Maintaining Dump Trucks

Dump Motor Operators are also responsible for maintaining the dump trucks they operate. They perform daily inspections and minor repairs to ensure the vehicles are in good working condition.

- Checking fluid levels, tire pressure, and brake systems.

- Making minor repairs such as replacing lights, filters, and hoses.

- Reporting any major maintenance issues or repairs to a supervisor.

3. Safety and Compliance

Dump Motor Operators must prioritize safety in their work. They follow safety regulations and operate dump trucks according to established procedures.

- Wearing appropriate safety gear such as hard hats, safety glasses, and work boots.

- Adhering to speed limits and traffic regulations.

- Inspecting the work area for hazards and taking necessary precautions.

4. Communication and Teamwork

Dump Motor Operators work closely with other team members, such as construction workers, supervisors, and other equipment operators. They communicate effectively to coordinate tasks and ensure smooth project execution.

- Communicating with supervisors to receive instructions and report on progress.

- Working with construction workers to load and unload materials.

- Coordinating with other equipment operators to avoid collisions and ensure efficient movement.

Interview Tips for Dump Motor Operators

Preparing thoroughly for an interview can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Role

Before the interview, research the company and the specific job role. Understand the company’s background, industry, and work culture.

- Visit the company’s website, read industry news, and connect with employees on LinkedIn.

- Review the job description carefully and identify the key responsibilities and skills required.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers. This will build your confidence and ensure you deliver concise and informative responses.

- Prepare answers to questions about your experience, skills, and why you are interested in the job.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your work.

3. Highlight Your Experience and Skills

Emphasize your relevant experience and skills during the interview. Quantify your accomplishments whenever possible.

- Provide examples of projects where you operated dump trucks and the tonnage of materials you transported.

- Highlight any safety certifications or training programs you have completed.

4. Be Enthusiastic and Professional

Project enthusiasm for the job and the company throughout the interview. Be polite, respectful, and maintain eye contact with the interviewer.

- Dress professionally and arrive on time for the interview.

- Thank the interviewer for their time and consideration.

5. Ask Questions

Asking thoughtful questions shows that you are engaged and interested in the job. Prepare a few questions to ask the interviewer at the end of the interview.

- Ask about the company’s safety protocols and training opportunities.

- Inquire about the project timelines and the role of a Dump Motor Operator in the overall construction process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dump Motor Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.