Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dupligraph Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

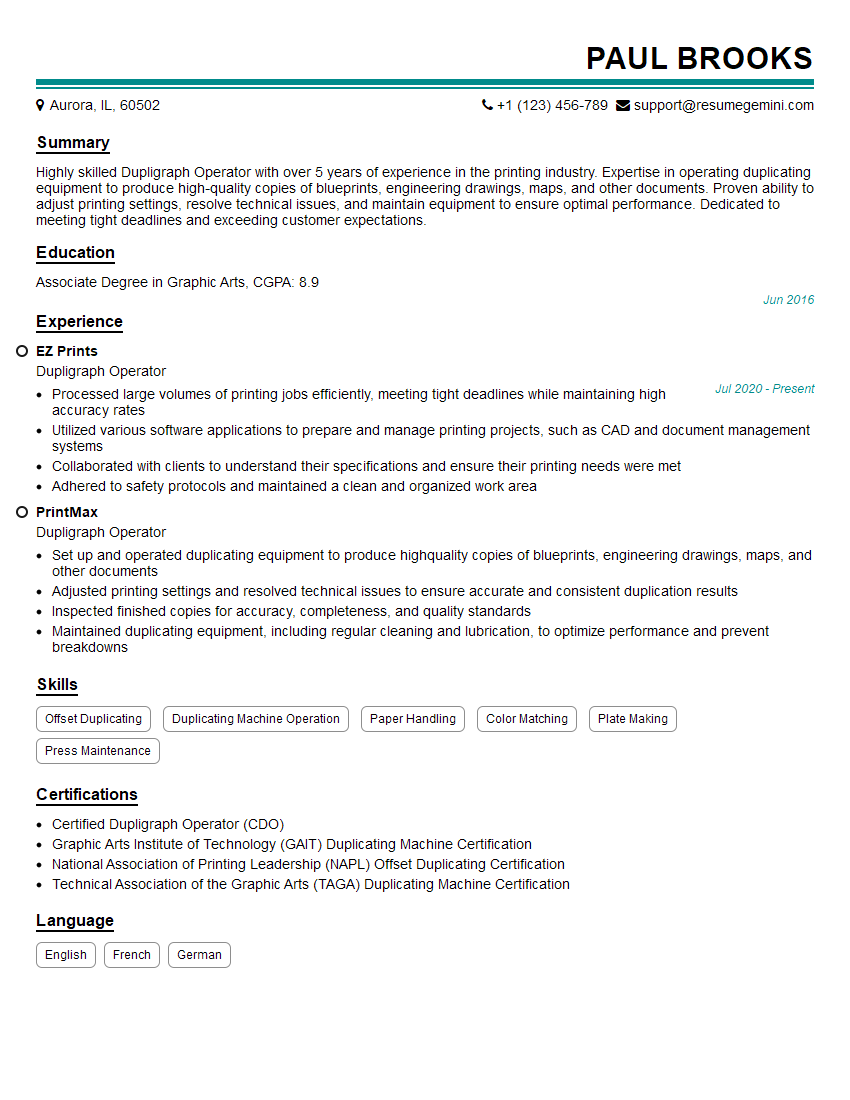

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dupligraph Operator

1. What are the different types of duplicating machines and their key features?

- Spirit duplicators: Use a master copy and a spirit solution to create copies. They are known for their low cost and high volume output.

- Stencil duplicators: Create copies using a stencil and ink. They offer high quality copies and can handle a wide range of paper sizes.

- Offset duplicators: Utilize a metal plate and ink to transfer images to paper. They produce high-quality copies that are comparable to professional printing.

- Digital duplicators: Employ digital technology to create copies. They offer fast speeds, high quality, and the ability to print on a variety of media.

2. Describe the process of preparing a master copy for duplicating.

Pre-processing:

- Select the original document.

- Ensure the document is clean and free of tears or creases.

- Adjust the contrast and sharpness if necessary.

Master creation:

- Insert the original into the duplicator’s master-making unit.

- Set the desired number of copies and other parameters.

- Create the master copy according to the machine’s instructions.

3. Explain the importance of maintaining proper ink levels in a duplicating machine.

- Quality control: Proper ink levels ensure consistent and high-quality copies.

- Machine health: Insufficient ink can damage the machine’s components, such as the print heads.

- Productivity: Monitoring ink levels helps prevent interruptions and downtime.

- Cost efficiency: Avoiding ink shortages and replacing ink cartridges at the optimal time saves money.

4. How do you troubleshoot common duplicating machine problems, such as paper jams and copy quality issues?

- Paper jams: Check the paper tray, remove jammed paper, and adjust the paper guides.

- Copy quality issues: Inspect the master copy, clean the print heads, and adjust the machine’s settings.

- Other problems: Refer to the machine’s manual, consult with colleagues, or contact technical support as needed.

5. What safety precautions should be taken when operating a duplicating machine?

- Keep hands away from moving parts.

- Use safety guards and follow manufacturer’s instructions.

- Handle chemicals, such as ink and cleaning solutions, with care.

- Report any electrical or mechanical issues immediately.

- Maintain a clean and organized work area.

6. How do you ensure that copies meet the required standards of quality and quantity?

- Use high-quality materials, such as paper and master copies.

- Calibrate the machine regularly and adjust settings as needed.

- Proofread copies and make adjustments if necessary.

- Maintain a clean and well-maintained machine.

- Follow established procedures and best practices.

7. Describe your experience in managing high-volume duplicating projects, including any challenges you encountered and how you overcame them.

Example Outline:

- Project description: Outline the scope and scale of the project.

- Challenges encountered: Describe any obstacles or difficulties faced, such as equipment issues, tight deadlines, or high demand.

- Solutions implemented: Explain how you addressed the challenges, including technical fixes, process improvements, or collaboration with colleagues.

- Results achieved: Quantify the success of your efforts, such as meeting deadlines, maintaining quality, or reducing costs.

8. How do you stay up-to-date on the latest advancements in duplicating technology?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Consult with vendors and manufacturers to learn about new products.

- Network with colleagues and share knowledge.

- Take advantage of training opportunities.

9. What is your understanding of color matching and calibration in duplicating?

- Color matching: Ensuring that colors on copies accurately match the original document.

- Calibration: Adjusting the machine to ensure consistent and accurate color reproduction.

- Importance: Color matching is crucial for maintaining brand consistency and reproducing images and graphics faithfully.

10. Explain the steps involved in maintaining and servicing a duplicating machine.

- Regular cleaning: Removing dust, debris, and ink stains.

- Lubrication: Applying lubricants to moving parts to reduce wear and ensure smooth operation.

- Component replacement: Replacing worn or damaged parts, such as print heads or fuser units.

- Calibration: Adjusting the machine’s settings to optimize performance and color accuracy.

- Troubleshooting: Diagnosing and resolving common problems to minimize downtime.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dupligraph Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dupligraph Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dupligraph Operators are responsible for setting up, operating, and troubleshooting duplicating and printing equipment to produce high-quality copies of documents, drawings, and other materials. Their specific duties may include:

1. Duplicating and printing

Operating duplicating and printing machines to produce copies of documents, drawings, and other materials.

- Ensuring that the equipment is properly set up and calibrated.

- Monitoring the printing process to ensure that the copies are of high quality.

2. Paper handling

Loading paper into the duplicating or printing machine, and ensuring that the paper is properly aligned.

- Unloading finished copies from the machine.

- Replenishing paper supplies.

3. Collating and finishing

Collating copies into sets, and stapling or binding them as required.

- Folding or drilling copies.

- Trimming or cutting copies to size.

4. Machine maintenance

Performing basic maintenance on duplicating and printing equipment.

- Cleaning the machine.

- Replacing toner or ink cartridges.

Interview Tips

Preparing for a Dupligraph Operator interview can help you make a great impression and increase your chances of getting the job. Here are some tips to help you prepare:

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture and the skills and experience they’re looking for in a Dupligraph Operator.

- Visit the company’s website to learn about their history, mission, and values.

- Read online reviews of the company to get an idea of what it’s like to work there.

- Talk to people you know who work for the company to get their insights.

2. Practice your answers to common interview questions

There are some common interview questions that you’re likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” It’s helpful to practice your answers to these questions so that you can deliver them confidently and clearly.

- Make a list of potential interview questions and write out your answers.

- Practice saying your answers out loud to a friend or family member.

- Time yourself to make sure that your answers are concise and to the point.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time to show that you respect the interviewer’s time.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Arrive at the interview location 10-15 minutes early.

4. Be yourself and be confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and upfront about your skills and experience.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be enthusiastic and show that you’re excited about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dupligraph Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!