Are you gearing up for an interview for a Durability Engineer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Durability Engineer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

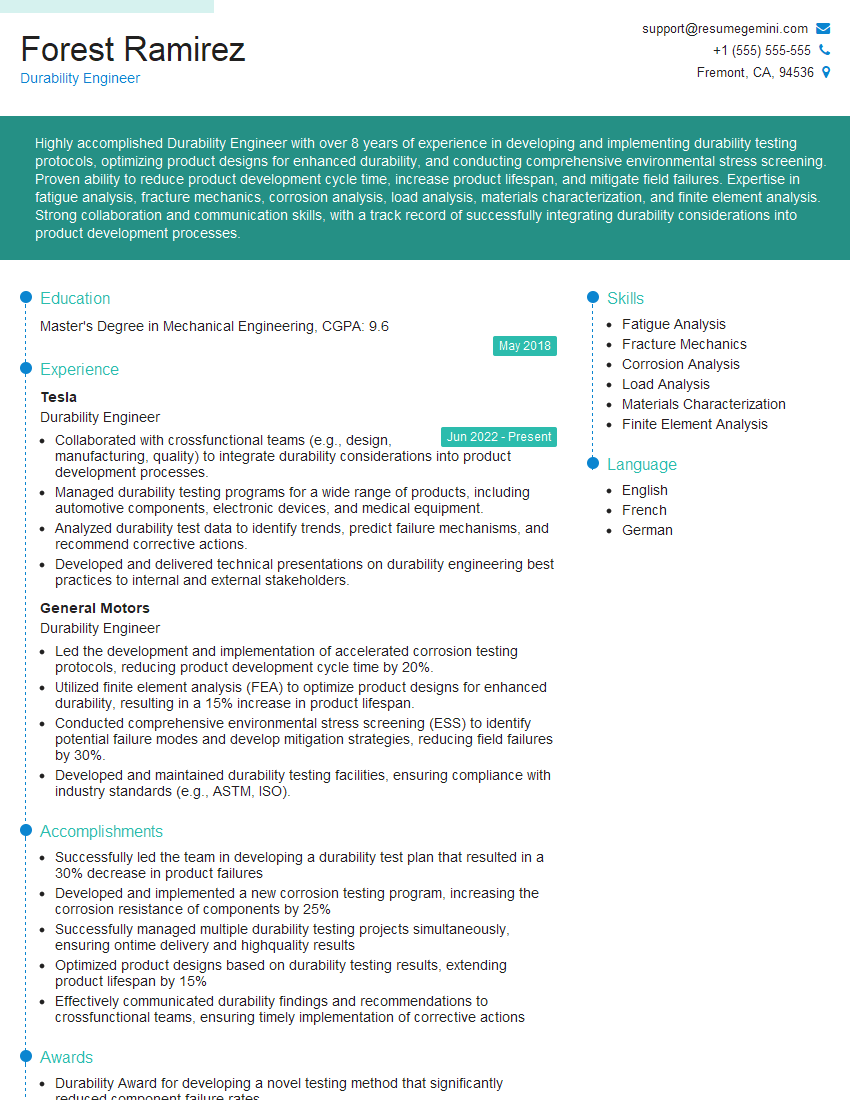

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Durability Engineer

1. What are the primary responsibilities of a Durability Engineer?

As a Durability Engineer, my core responsibilities include:

- Identifying and assessing potential durability issues in products and materials

- Developing and implementing testing protocols to evaluate durability performance

- Analyzing test data to determine the causes of durability failures and recommend corrective actions

- Collaborating with design and manufacturing teams to improve product durability

- Staying abreast of industry best practices and emerging technologies in durability engineering

2. Describe the different types of durability testing you have experience with.

Throughout my career, I have gained extensive experience in a wide range of durability testing techniques, including:

Accelerated aging tests:

- UV exposure testing

- Thermal cycling

- Humidity testing

Mechanical tests:

- Fatigue testing

- Impact testing

- Stress relaxation testing

Environmental tests:

- Salt spray testing

- Corrosion testing

- Chemical resistance testing

3. How do you determine the appropriate durability testing methods for a specific product or material?

When selecting durability testing methods, I meticulously consider several key factors:

- The intended use and environment of the product

- The materials used in its construction

- The potential failure modes

- The available resources and budget

- Industry standards and best practices

4. What are some of the common durability issues you have encountered and how did you address them?

In my experience, I have encountered various durability issues, including:

- Corrosion: Implemented corrosion-resistant coatings and materials

- Fatigue: Optimized designs to reduce stress concentrations and increase fatigue life

- UV degradation: Introduced UV-stabilizers and protective coatings

- Environmental embrittlement: Selected materials with improved environmental resistance

5. How do you stay up-to-date on the latest advancements in durability engineering?

To remain current with industry advancements, I actively participate in the following:

- Attending conferences and workshops

- Subscribing to technical journals and publications

- Participating in professional organizations, such as the Durability Society of America

- Collaborating with experts in academia and industry

6. What is your approach to developing and implementing a comprehensive durability testing program?

My approach to developing and implementing a durability testing program encompasses several key steps:

- Define testing objectives: Clearly establish the goals and scope of the testing program

- Identify potential failure modes: Conduct thorough failure analysis to determine potential weak points

- Select appropriate testing methods: Choose the most suitable testing methods based on the identified failure modes

- Design test protocols: Develop detailed test procedures to ensure consistency and accuracy

- Execute testing: Conduct the testing program meticulously and document the results

- Analyze data: Interpret the test results and identify areas for improvement

- Communicate findings: Disseminate the test results to stakeholders and recommend corrective actions

7. How do you ensure the reliability and validity of your testing results?

To ensure the reliability and validity of my testing results, I strictly adhere to the following principles:

- Calibration and maintenance: Regularly calibrate and maintain all testing equipment to industry standards

- Control variables: Meticulously control environmental conditions and other variables during testing

- Replicate tests: Conduct multiple tests to confirm the reproducibility of the results

- Peer review: Seek feedback from colleagues and experts to validate the testing methodology and conclusions

8. Describe a time when you faced a particularly challenging durability problem. How did you approach it and what was the outcome?

One particularly challenging durability problem I encountered involved the premature cracking of a plastic component in an automotive application. I conducted a comprehensive investigation, including:

- Failure analysis to identify the root cause of the cracking

- Material characterization to determine the mechanical properties of the plastic

- Design evaluation to assess the stress distribution in the component

- Accelerated aging tests to simulate real-world conditions

Based on the findings, I recommended a combination of design modifications and material improvements. The implemented solutions effectively addressed the durability issue, resulting in a significant increase in the component’s lifespan.

9. How do you balance the need for durability with other design considerations, such as cost and manufacturability?

Striking a balance between durability, cost, and manufacturability requires a holistic approach:

- Early involvement: Engage with design and manufacturing teams from the concept stage to identify potential durability concerns and develop cost-effective solutions

- Value analysis: Conduct value engineering studies to optimize designs for durability while minimizing costs

- Alternative materials: Explore alternative materials with improved durability properties while considering cost and processing requirements

- Design for durability: Implement design principles that enhance durability, such as stress reduction and corrosion protection

10. What is your understanding of the role of durability engineering in sustainable product development?

Durability engineering plays a crucial role in sustainable product development by:

- Extending product lifespan: Enhancing durability reduces the need for frequent replacements, reducing waste and conserving resources

- Minimizing environmental impact: Durable products require fewer repairs and replacements, reducing the consumption of energy and materials

- Improving safety: Durable products are less prone to unexpected failures, ensuring safety for users and the environment

- Increasing customer satisfaction: Durable products provide a positive customer experience, fostering brand loyalty

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Durability Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Durability Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Durability Engineer is responsible for ensuring the durability and performance of products in a variety of industries, including automotive, aerospace, and electronics. They work with design engineers to develop and implement testing methods, and they analyze data to identify and mitigate potential durability issues.

1. Design and Implementation of Testing Methods

The Durability Engineer is responsible for designing and implementing testing methods to evaluate the durability of products and materials. These methods may include mechanical testing, environmental testing, and corrosion testing.

- Design and conduct laboratory and field tests to evaluate the durability of materials and products

- Develop and implement test protocols to assess product performance under various conditions

2. Data Analysis and Interpretation

The Durability Engineer is responsible for analyzing and interpreting data from durability tests. They use this data to identify potential durability issues and to develop mitigation strategies.

- Analyze test data to identify trends and patterns

- Interpret test results and make recommendations for product design and manufacturing improvements

3. Failure Analysis

The Durability Engineer is responsible for investigating product failures and identifying the root cause of the failure. They use this information to develop corrective action plans to prevent similar failures from occurring in the future.

- Investigate product failures to determine the cause of failure

- Develop and implement corrective action plans to prevent similar failures from occurring

4. Collaboration with Design Engineers

The Durability Engineer works closely with design engineers to identify and mitigate potential durability issues. They provide input on product design and manufacturing processes to ensure that products are designed and manufactured to withstand the intended use conditions.

- Collaborate with design engineers to optimize product design for durability

- Provide guidance on material selection and manufacturing processes to enhance product durability

Interview Tips

Preparing for an interview for a Durability Engineer position can be challenging, but there are a few key things you can do to increase your chances of success.

1. Research the company and the position

Before you go to an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the position.

- Visit the company’s website and read about their mission, values, and products/services.

- Read the job description carefully and identify the key skills and experience that the company is looking for.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “tell me about yourself” and “why are you interested in this position?”. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Prepare a brief overview of your skills and experience, highlighting those that are most relevant to the position you are applying for.

- Think about why you are interested in the position and the company, and be prepared to articulate your reasons clearly.

3. Be prepared to talk about your experience in durability engineering

The interviewer will likely ask you about your experience in durability engineering. Be prepared to discuss your past projects, the methods you used, and the results you achieved.

- Provide specific examples of projects you have worked on, highlighting your role and responsibilities.

- Discuss the test methods you used and how you analyzed the data to identify potential durability issues.

4. Be prepared to talk about your problem-solving skills

Durability engineers often need to solve complex problems. Be prepared to discuss your problem-solving skills and how you approach solving problems.

- Describe a time when you faced a challenge and how you overcame it.

- Explain your approach to problem-solving and how you prioritize and manage your work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Durability Engineer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.