Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dural Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dural Mechanic so you can tailor your answers to impress potential employers.

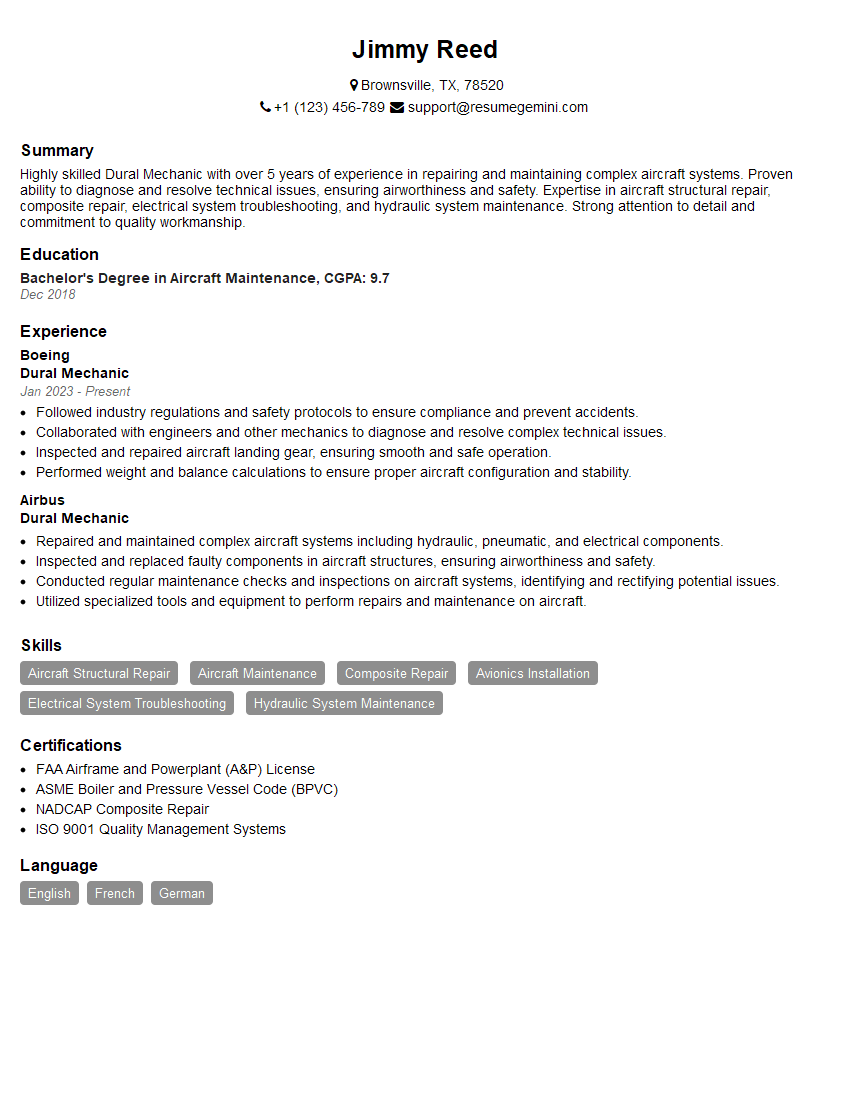

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dural Mechanic

1. What are the key components of a duralumin structure?

The key components of a duralumin structure include:

- Skin

- Stringers

- Frames

- Bulkheads

- Riveted joints

- Adhesive joints

2. How do you ensure the structural integrity of a duralumin structure during repairs?

Inspection

- Visual inspection

- Non-destructive testing (NDT)

Repair

- Patching

- Replacement

- Reinforcement

Quality control

- Inspection

- Testing

- Documentation

3. What are the different types of rivets used in duralumin structures?

The different types of rivets used in duralumin structures include:

- Solid rivets

- Blind rivets

- Countersunk rivets

- Flush rivets

- Cherry rivets

- Explosive rivets

4. What are the different types of adhesives used in duralumin structures?

The different types of adhesives used in duralumin structures include:

- Epoxy adhesives

- Polyurethane adhesives

- Acrylic adhesives

- Phenolic adhesives

- Film adhesives

5. What are the different types of corrosion that can affect duralumin structures?

The different types of corrosion that can affect duralumin structures include:

- Pitting corrosion

- Crevice corrosion

- Stress corrosion cracking

- Filiform corrosion

- Exfoliation corrosion

6. What are the different methods used to protect duralumin structures from corrosion?

The different methods used to protect duralumin structures from corrosion include:

- Anodizing

- Cladding

- Painting

- Inhibitors

- Protective coatings

7. What are the different types of damage that can occur to duralumin structures?

The different types of damage that can occur to duralumin structures include:

- Dents

- Scratches

- Cracks

- Bends

- Corrosion

8. What are the different methods used to repair damage to duralumin structures?

The different methods used to repair damage to duralumin structures include:

- Patching

- Replacement

- Reinforcement

- Welding

- Adhesive bonding

9. What are the different safety precautions that must be taken when working with duralumin structures?

The different safety precautions that must be taken when working with duralumin structures include:

- Wear appropriate personal protective equipment (PPE)

- Use proper tools and equipment

- Follow safe work practices

- Be aware of the hazards associated with duralumin

- Take precautions to prevent accidents

10. What are the different quality control procedures that must be followed when working with duralumin structures?

The different quality control procedures that must be followed when working with duralumin structures include:

- Inspection

- Testing

- Documentation

- Calibration

- Traceability

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dural Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dural Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dural Mechanic is a highly skilled professional responsible for the maintenance, repair, and inspection of aircraft structures and components made of duralumin, a strong and lightweight aluminum alloy commonly used in aircraft construction. Their key responsibilities include:

1. Aircraft Maintenance and Repair

Inspecting, maintaining, and repairing aircraft structures, including fuselages, wings, and control surfaces, to ensure structural integrity and flight safety.

- Performing routine inspections, visual checks, and NDT (non-destructive testing) to detect defects, corrosion, or damage.

- Repairing and replacing damaged or worn components, using specialized tools and techniques, such as welding, riveting, and forming.

- Overhauling and modifying aircraft structures to meet safety regulations and improve performance.

2. Structural Analysis and Evaluation

Evaluating structural integrity, assessing damage, and determining necessary repairs for aircraft.

- Performing structural analysis using engineering principles and tools to identify potential failure points and recommend solutions.

- Interpreting technical drawings, specifications, and manuals to ensure proper repair and maintenance procedures.

- Coordinating with engineers and other technicians to resolve complex structural issues.

3. Fabrication and Modification

Fabricating and modifying aircraft parts and components, following engineering drawings and specifications.

- Creating prototype parts and components using advanced manufacturing techniques.

- Modifying existing parts to improve performance, reduce weight, or enhance functionality.

- Working with composite materials, such as carbon fiber and fiberglass, to create lightweight and durable aircraft structures.

4. Documentation and Quality Control

Maintaining accurate records of maintenance, repairs, and modifications performed on aircraft.

- Documenting all inspection findings, repair procedures, and testing results.

- Ensuring compliance with regulatory requirements and industry standards.

- Conducting quality control checks to ensure the integrity and functionality of repaired and modified aircraft components.

Interview Tips

To ace an interview for a Dural Mechanic position, candidates should prepare thoroughly and present themselves professionally. Here are some tips and hacks to help you succeed:

1. Research the Company and Position

Research the company’s history, values, and current projects to demonstrate your interest and understanding of the organization.

- Visit the company’s website, read industry news, and search for recent company announcements.

- Review the job description thoroughly and identify the key skills and qualifications required.

2. Practice Your Answers

Practice answering common interview questions to avoid hesitation or rambling.

- Prepare examples of your work experience, skills, and accomplishments that demonstrate your suitability for the role.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific and quantifiable examples.

3. Emphasize Your Technical Skills

Highlight your knowledge of duralumin properties, structural analysis, fabrication techniques, and quality control procedures.

- Describe your experience with various NDT methods and repair techniques.

- Discuss your familiarity with aircraft structures, engineering principles, and safety regulations.

4. Show Your Passion for Aviation

Express your passion for aviation and your eagerness to contribute to the industry.

- Share your experience in aircraft maintenance, modeling, or other related activities.

- Explain how your interest in aviation aligns with the company’s mission and values.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewers, demonstrating your engagement and interest in the company.

- Ask about the company’s safety culture, training opportunities, and career growth potential.

- Inquire about specific projects or initiatives that the company is involved in.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dural Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.