Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dust Control Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dust Control Engineer so you can tailor your answers to impress potential employers.

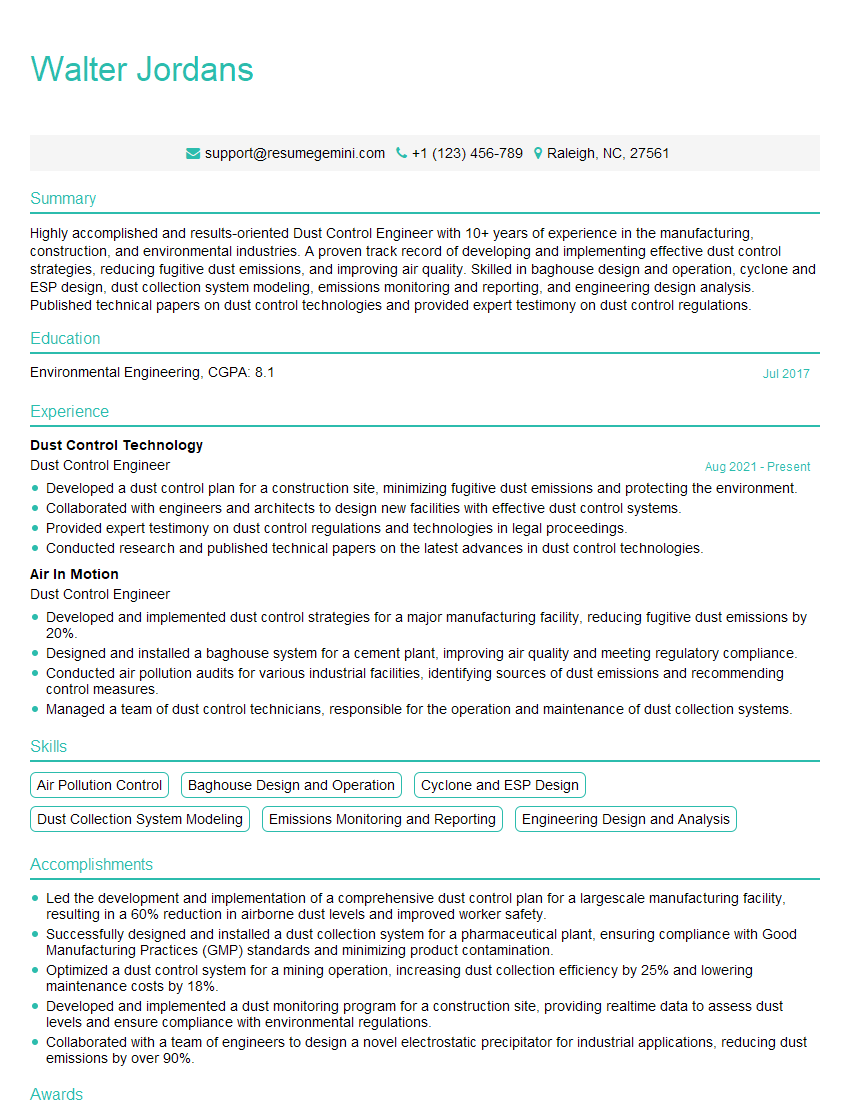

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dust Control Engineer

1. Explain the principles of dust control engineering?

Dust control engineering involves the application of scientific and engineering principles to manage and mitigate dust emissions in various industries and environments. Here are the key principles:

- Emission Source Identification: Determining the sources of dust emissions, such as industrial processes, material handling, or natural occurrences, is crucial for effective control.

- Dust Generation and Dispersion: Understanding the mechanisms of dust generation and dispersion, including particle size distribution, wind patterns, and material properties, is essential for designing control measures.

- Dust Control Technologies: Employing a range of technologies, such as dust collectors (cyclones, bag filters, electrostatic precipitators), wet suppression systems, and process modifications, to capture, remove, or suppress dust emissions.

- Airflow Management: Controlling airflow patterns and ventilation systems to optimize dust collection efficiency and prevent dust dispersion within facilities or the environment.

- Monitoring and Evaluation: Continuously monitoring dust emissions and evaluating the effectiveness of control measures, adjusting strategies as needed to maintain compliance with regulations and minimize environmental impact.

2. Describe the different types of dust collectors and their applications?

Cyclone Collectors

- Operate on the principle of centrifugal force to separate dust particles from the airstream.

- Suitable for collecting large and heavy particles in high-volume applications, such as woodworking, metalworking, and mining.

Bag Filters

- Use fabric filter bags to trap dust particles as the airstream passes through.

- Highly efficient in capturing fine dust particles, suitable for industries like pharmaceutical manufacturing, chemical processing, and food production.

Electrostatic Precipitators (ESPs)

- Apply an electrostatic charge to dust particles, causing them to migrate to and adhere to collector plates.

- Very effective in removing fine and submicron particles, commonly used in power plants, steel mills, and cement factories.

Wet Scrubbers

- Involve passing the airstream through a liquid spray to capture dust particles by impaction and absorption.

- Suitable for industries with high moisture content or corrosive dust, such as paper mills, chemical plants, and food processing.

3. Discuss the factors to consider when designing a dust control system?

Designing an effective dust control system requires careful consideration of various factors:

- Dust Characteristics: Particle size distribution, density, and chemical composition of the dust.

- Process Parameters: Dust generation rate, airflow patterns, and material handling methods.

- Environmental Regulations: Compliance with applicable air quality standards and emission limits.

- Space Constraints: Availability of space for installing dust collectors and associated equipment.

- Energy Efficiency: Minimizing energy consumption while maintaining desired efficiency levels.

- Maintenance and Accessibility: Ease of access for routine maintenance and cleaning.

4. How do you assess the efficiency of a dust control system?

Assessing the efficiency of a dust control system involves the following steps:

- Establishing Performance Criteria: Defining specific performance goals based on regulatory requirements or desired outcomes.

- Monitoring Dust Emissions: Conducting periodic monitoring to measure dust concentrations before and after the control system.

- Calculating Efficiency: Determining the percentage reduction in dust emissions achieved by the system.

- Evaluating Performance: Comparing the measured efficiency against the established performance criteria.

- Making Adjustments: Implementing modifications or upgrades to the system as needed to optimize efficiency.

5. Describe the role of ventilation in dust control?

Ventilation plays a crucial role in dust control by:

- Diluting Dust Concentrations: Introducing clean air to disperse and reduce the concentration of dust particles in the air.

- Creating Airflow Patterns: Directing airflow towards dust sources and collection points to facilitate dust capture.

- Preventing Dust Accumulation: Maintaining adequate air movement to prevent dust from settling on surfaces and becoming a potential source of resuspension.

6. Discuss the importance of routine maintenance for dust control systems?

Regular maintenance is essential for optimal performance and longevity of dust control systems:

- Preserving Efficiency: Regular cleaning and servicing of dust collectors, filters, and other components ensure they operate efficiently and effectively.

- Preventing System Failures: Proactive maintenance reduces the risk of breakdowns or malfunctions, minimizing downtime and production losses.

- Extending Equipment Life: Proper maintenance prolongs the lifespan of dust control equipment, saving on replacement costs and reducing environmental waste.

7. How do you handle dust control challenges in outdoor environments?

Dust control in outdoor environments presents unique challenges:

- Wind and Weather Conditions: Wind can disperse dust, while rain can impact the effectiveness of dust suppression techniques.

- Large Areas: Outdoor spaces can be vast, requiring extensive measures to control dust over a wide area.

- Variable Dust Sources: Dust sources in outdoor environments can be transient and difficult to pinpoint.

- Use of Dust Suppressants: Applying chemical or natural dust suppressants to stabilize dust and prevent resuspension is often necessary.

- Erosion Control: Implementing measures to prevent erosion and minimize dust generation from exposed soil or other surfaces is crucial.

8. Describe the latest advancements in dust control technologies?

- High-Efficiency Filters: Advanced filter media and technologies provide higher dust capture efficiency, reducing emissions and improving air quality.

- Electrostatic Precipitation Enhancements: Innovations in electrode design and power supplies improve particle charging and collection efficiency.

- Nanotechnology-Based Solutions: Novel materials and coatings enhance dust adhesion and filtration performance.

- Remote Monitoring and Control: Wireless sensors and IoT platforms allow for real-time monitoring and remote control of dust control systems.

- Artificial Intelligence (AI): AI algorithms optimize system performance, predict maintenance needs, and provide real-time decision support.

9. How do you stay updated with the latest industry regulations and best practices in dust control?

- Attending Industry Conferences: Participating in conferences and workshops provides opportunities to learn about new technologies, regulations, and industry trends.

- Reading Technical Literature: Reviewing research papers, industry publications, and technical journals keeps me abreast of advancements and emerging practices.

- Networking with Professionals: Connecting with other dust control engineers, researchers, and industry experts through professional organizations and online forums fosters knowledge exchange.

- Seeking Continuing Education: Pursuing advanced degrees, certifications, or specialized training programs ensures I stay current with the latest developments.

10. What are the key qualities and skills required to excel as a Dust Control Engineer?

- Technical Expertise: Strong understanding of dust control principles, technologies, and regulations.

- Analytical Skills: Ability to analyze dust sources, emission patterns, and system performance to develop effective control strategies.

- Problem-Solving Abilities: Capacity to identify and overcome challenges in the design, implementation, and maintenance of dust control systems.

- Communication Skills: Proficiency in presenting technical information clearly and effectively to stakeholders, including engineers, clients, and regulators.

- Innovation and Adaptability: Openness to exploring new technologies and finding creative solutions to dust control problems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dust Control Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dust Control Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dust Control Engineers are responsible for developing and implementing strategies to minimize dust emissions in industrial and commercial settings. Their key responsibilities include:

1. Dust Emissions Monitoring

Monitoring and evaluating dust emissions from various sources, such as manufacturing processes, construction sites, and mining operations.

2. Dust Control System Design

Designing and recommending appropriate dust control systems, such as baghouses, electrostatic precipitators, and wet scrubbers.

3. System Installation and Maintenance

Overseeing the installation and maintenance of dust control systems to ensure optimal performance and compliance with environmental regulations.

4. Research and Development

Conducting research and staying abreast of advancements in dust control technologies to identify and implement new and innovative solutions.

Interview Tips

To ace an interview for a Dust Control Engineer position, follow these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s business, products, and industry best practices. Demonstrate your understanding of the specific dust control challenges they face.

2. Highlight Relevant Skills and Experience

Emphasize your technical expertise in dust control, including knowledge of different systems, regulations, and monitoring methods.

3. Showcase Problem-Solving Abilities

Provide examples of how you have successfully identified and solved dust control problems in previous roles. Explain your approach and the positive outcomes.

4. Prepare Industry-Specific Questions

Ask thoughtful questions about the company’s dust control practices, environmental compliance, and industry trends to demonstrate your knowledge and engagement.

5. Dress Professionally and Be Punctual

Make a good first impression by dressing appropriately and arriving on time for the interview.

6. Be Enthusiastic and Confident

Convey your passion for dust control and your confidence in your abilities. Show that you are eager to contribute to the team and make a positive impact.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dust Control Engineer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.