Are you gearing up for an interview for a Dye Box Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Dye Box Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

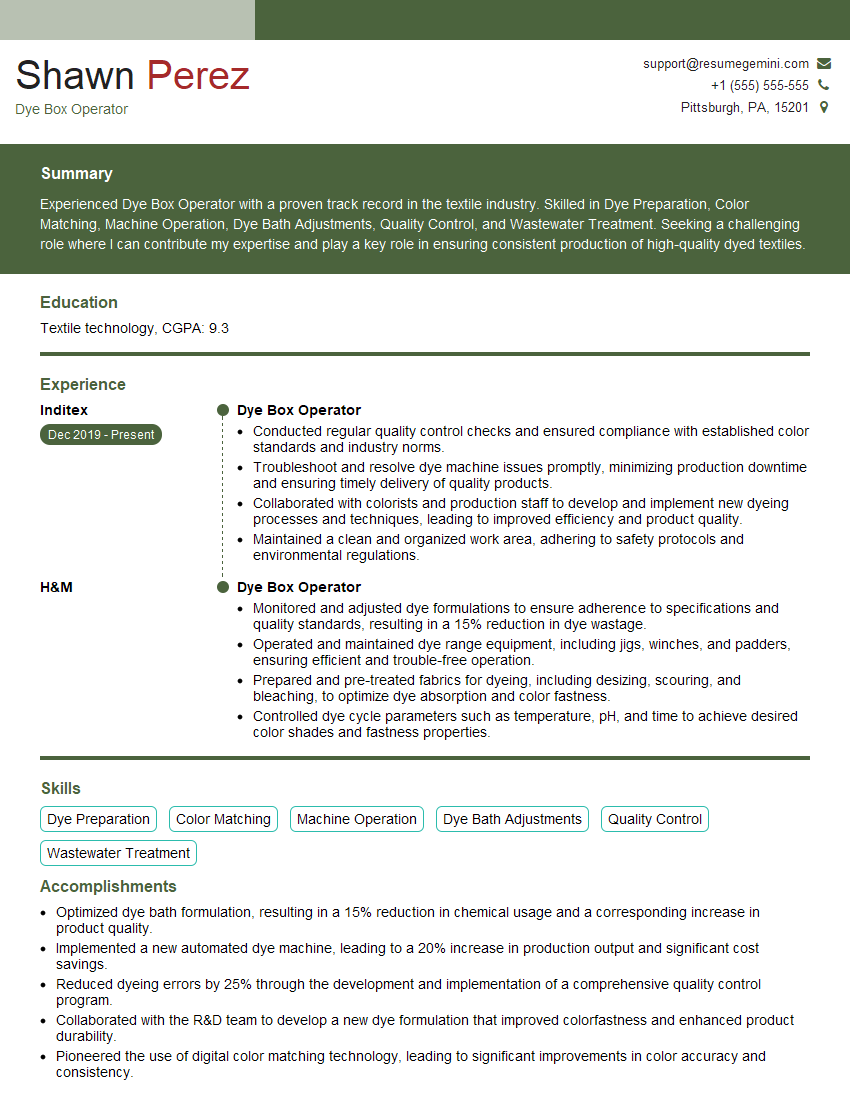

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dye Box Operator

1. What are the key responsibilities of a Dye Box Operator?

During my experience as a Dye Box Operator, I have developed a comprehensive understanding of the role’s key responsibilities. These include:

- Operating and maintaining dye boxes and associated equipment

- Accurately dispensing and mixing dyes and chemicals

- Performing dye tests and evaluations

- Monitoring and controlling dyeing processes to ensure quality and efficiency

- Maintaining a clean and organized work area

2. Explain the different types of dyeing processes and their applications.

Natural Dyeing

- Using natural materials like plants, insects, and minerals to produce dyes

- Provides unique colors and eco-friendly options

Synthetic Dyeing

- Employs synthetically created dyes derived from chemicals

- Offers a wider range of colors and higher colorfastness

Pigment Dyeing

- Involves using insoluble pigments that are dispersed in a liquid medium

- Provides excellent light and wash fastness

Discharge Dyeing

- Removes the original color of the fabric before applying a new dye

- Used to create intricate patterns and designs

3. Describe the importance of color matching in dyeing.

Color matching is crucial in dyeing to achieve consistent and accurate results. It ensures that:

- Products meet customer specifications and quality standards

- Different batches of the same color appear uniform

- Rejects and customer complaints are minimized

- Brand reputation and customer satisfaction are maintained

4. What are the common challenges faced by Dye Box Operators and how do you overcome them?

Dye Box Operators often encounter challenges such as:

- Color variations: Overcome by using precise measuring and mixing techniques, following standardized recipes, and conducting regular color tests.

- Equipment malfunctions: Quickly identify and troubleshoot issues, perform regular maintenance, and have backup equipment available.

- Fabric defects: Inspect fabric before dyeing, use appropriate dyeing techniques, and communicate with upstream processes to prevent defects.

- Environmental concerns: Follow safety regulations, properly dispose of chemicals, and adhere to sustainable dyeing practices.

5. How do you ensure the safety and quality of dyed products?

Ensuring safety and quality in dyed products involves:

- Following established safety protocols: Wearing appropriate protective gear, handling chemicals safely, and maintaining a clean work environment.

- Adhering to quality standards: Conducting regular dye tests, monitoring process parameters, and inspecting finished products to meet customer requirements.

- Maintaining equipment: Regularly calibrating and maintaining dyeing equipment to ensure accuracy and efficiency.

- Continuous improvement: Staying updated on new dyeing techniques, technologies, and industry best practices.

6. What are your strengths and weaknesses as a Dye Box Operator?

Strengths:

- Expertise in various dyeing processes

- Strong attention to detail and accuracy

- Ability to work independently and as part of a team

- Excellent troubleshooting and problem-solving skills

Weaknesses:

- Limited experience with certain specialized dyeing techniques (willing to learn)

- Can be sensitive to strong chemical odors (taking necessary precautions)

7. How do you stay updated with advancements in dyeing technology?

To stay updated with advancements in dyeing technology, I actively engage in the following practices:

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Network with other Dye Box Operators and professionals

- Participate in online forums and discussions

- Explore research and development initiatives

8. What are the environmental considerations in dyeing and how do you address them?

Minimizing environmental impact in dyeing involves:

- Wastewater treatment: Implementing effective wastewater treatment systems to reduce harmful effluents.

- Chemical management: Using eco-friendly dyes and chemicals, optimizing their usage, and disposing of them responsibly.

- Energy efficiency: Employing energy-efficient dyeing equipment and processes.

- Sustainable sourcing: Opting for dyes and fabrics from sustainable sources.

- Employee training: Educating employees on environmental best practices.

9. How do you handle variations in fabric quality and how do you adjust your dyeing process accordingly?

Handling variations in fabric quality requires:

- Fabric evaluation: Assessing fabric properties, such as fiber content, construction, and absorbency, before dyeing.

- Recipe adjustment: Modifying dye concentrations, pH levels, and dyeing times based on fabric characteristics.

- Process optimization: Fine-tuning dyeing parameters, such as temperature, agitation, and duration, to achieve optimal results.

- Color testing: Conducting regular color tests to ensure consistency and meet customer specifications.

- Communication: Collaborating with upstream processes to address fabric quality issues and improve dyeing outcomes.

10. How do you ensure that dyed products meet customer requirements and industry standards?

Meeting customer requirements and industry standards involves:

- Clear communication: Understanding customer specifications and industry regulations.

- Color matching: Accurately matching colors using standardized recipes and color measurement devices.

- Quality control: Conducting thorough inspections, testing, and documentation to ensure product quality.

- Continuous improvement: Analyzing production data, customer feedback, and industry trends to identify areas for improvement.

- Compliance: Adhering to safety, environmental, and ethical standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dye Box Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dye Box Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dye Box Operators are responsible for operating and maintaining dye boxes used in the dyeing process of textiles, yarns, and other materials. They ensure that the dyeing process meets the specified color, shade, and quality standards.

1. Dyeing Operations

Perform dyeing operations according to established procedures and specifications.

- Load and unload dye boxes with materials.

- Monitor and adjust dye bath temperature, pH levels, and other process parameters.

2. Equipment Maintenance

Maintain and calibrate dye boxes and related equipment to ensure optimal performance.

- Clean and inspect dye boxes, pumps, and filters.

- Perform minor repairs and troubleshoot equipment issues.

3. Quality Control

Monitor the dyeing process and conduct quality checks to ensure that the dyed materials meet specifications.

- Inspect dyed materials for color uniformity, shade, and defects.

- Document dye bath parameters and quality control results.

4. Safety and Compliance

Adhere to safety protocols and regulatory requirements related to dyeing operations.

- Wear appropriate personal protective equipment (PPE).

- Follow proper handling and disposal procedures for chemicals and dyes.

Interview Tips

Preparing for a Dye Box Operator interview requires a combination of technical knowledge, industry experience, and strong communication skills. Here are some tips to help candidates ace the interview:

1. Highlight Relevant Experience

Emphasize your practical experience in operating and maintaining dye boxes. Showcase your ability to monitor and adjust process parameters, perform equipment maintenance, and ensure quality control.

- Example: “In my previous role, I was responsible for operating a fleet of dye boxes, ensuring consistent color quality and meeting production targets.”

2. Demonstrate Technical Proficiency

Review the fundamentals of dyeing processes, including color theory, dye chemistry, and equipment operation. Be prepared to discuss your understanding of the different dyeing techniques and their applications.

- Example: “I have a strong understanding of the principles of disperse dyeing and its use in achieving vibrant colors on synthetic fibers.”

3. Emphasize Quality Control

Highlight your commitment to quality control and your ability to identify and correct errors. Describe your experience in conducting inspections, maintaining documentation, and adhering to quality standards.

- Example: “I implemented a quality control program that resulted in a significant reduction in product defects, improving customer satisfaction.”

4. Showcase Safety Awareness

Emphasize your understanding of safety protocols in the dye box operation. Discuss your experience in handling chemicals, wearing PPE, and following proper disposal procedures.

- Example: “I have received comprehensive training on hazardous materials handling and emergency response procedures, ensuring a safe work environment.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dye Box Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!