Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dye-House Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

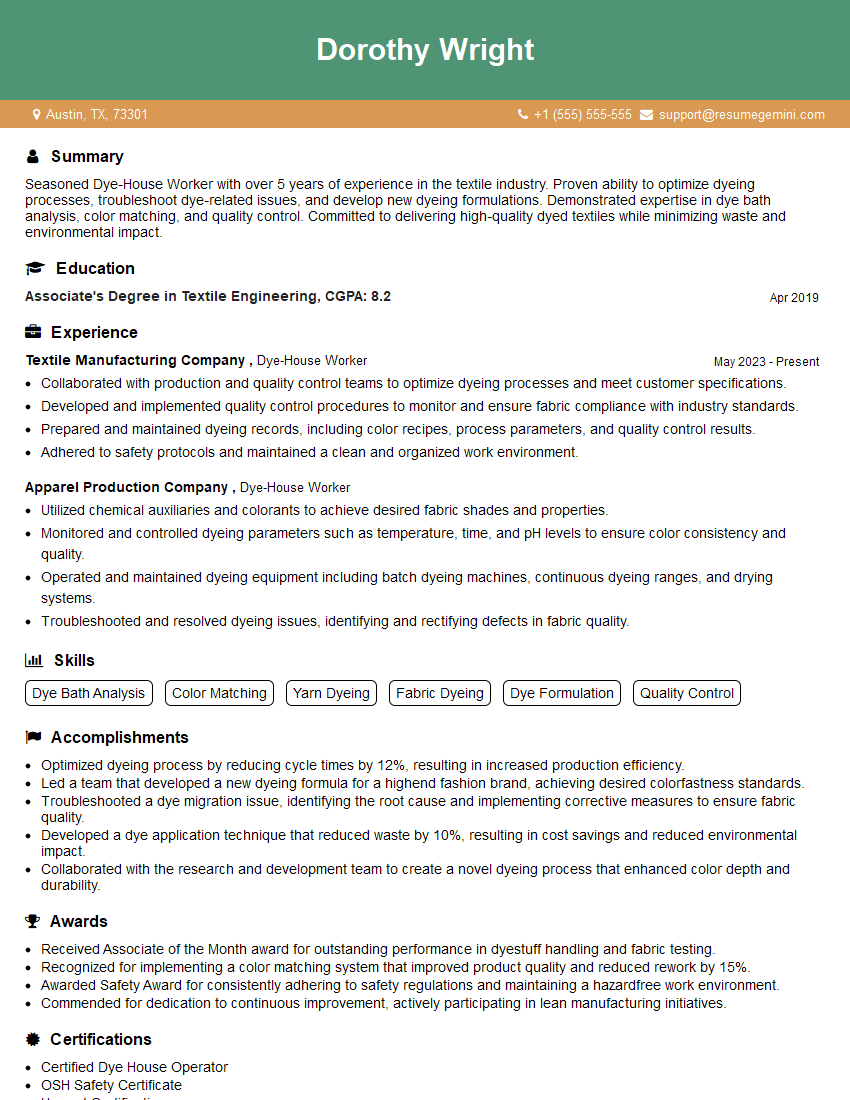

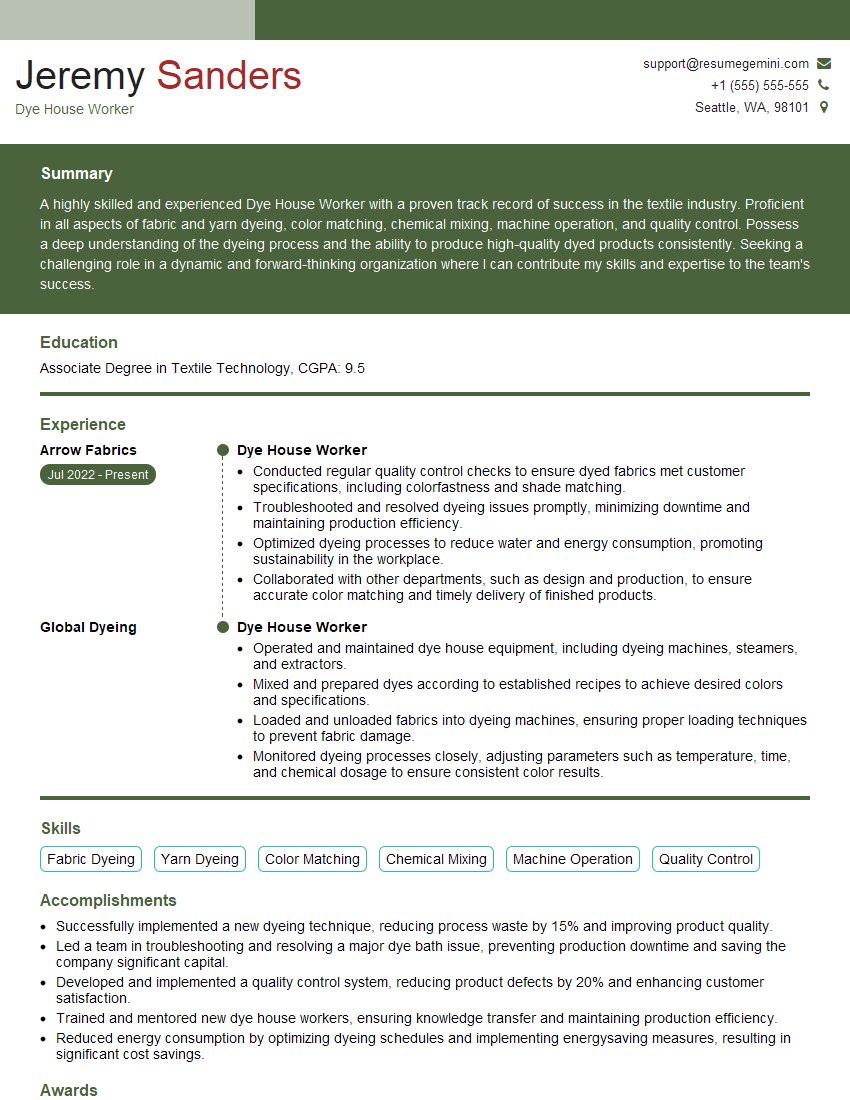

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dye-House Worker

1. Explain the process of dyeing fabrics in detail?

The process of dyeing fabrics involves several steps to impart color to the fabric:

- Preparing the fabric: The fabric is first prepared by removing impurities and scouring it to ensure even absorption of the dye.

- Selecting the right dye: Dyes are chosen based on their chemical compatibility with the fabric and desired color.

- Mixing the dye solution: The dye is dissolved in water or a solvent to create a dyeing solution.

- Dyeing the fabric: The fabric is immersed in the dye solution and heated to facilitate dye penetration. Different techniques, such as exhaustion or continuous dyeing, are used.

- Rinsing and finishing: After dyeing, the fabric is rinsed thoroughly to remove excess dye. Additional treatments, like softening or water-repelling agents, may be applied.

2. What is the difference between direct and disperse dyes?

Direct dyes:

- Water-soluble and directly bond to the fiber.

- Suitable for cellulosic fibers (e.g., cotton, rayon).

- Offer good wash fastness and colorfastness.

Disperse dyes:

- Insoluble in water and require carriers to penetrate hydrophobic fibers.

- Used for synthetic fibers (e.g., polyester, nylon).

- Provide good color depth and lightfastness.

3. Describe the principles of color matching in dyeing?

Color matching involves reproducing a desired color shade precisely. It requires a deep understanding of color theory and matching techniques:

- Munsell Color System: This system defines colors based on hue, value, and chroma.

- Metamerism: Matching colors under different light sources is essential to avoid discrepancies.

- Tinting and shading: Adding small amounts of secondary colors to the base dye to adjust the shade.

- Shade cards and spectrophotometers: Tools used to compare and quantify color shades.

4. Discuss the importance of pH control in dyeing?

pH control is crucial because it affects the dye’s behavior and the dyeing process:

- Dye solubility: Different dyes have optimal pH ranges for solubility and efficacy.

- Fiber receptivity: The charge of the fiber surface is pH-dependent, influencing dye absorption.

- Colorfastness: pH can affect dye fixation and resistance to fading.

- Equipment corrosion: Acidic or alkaline conditions can damage dyeing machinery.

5. What are the common problems encountered in dyeing and how do you troubleshoot them?

Troubleshooting dyeing problems requires a systematic approach:

- Uneven dyeing: Check pH, temperature, dye concentration, and fabric preparation.

- Color bleeding: Use colorfast dyes, increase rinsing, and apply fixing agents.

- Dye migration: Prevent by using compatible dyes, proper pH control, and appropriate dyeing techniques.

- Dye fading: Ensure lightfast dyes are used and consider using UV protectants.

- Machine malfunctions: Inspect equipment regularly, calibrate sensors, and ensure proper maintenance.

6. Explain the role of mordants in dyeing?

Mordants are substances used to improve the binding of dyes to fibers:

- Metal salts: Form complexes with the dye, enhancing its affinity for the fiber (e.g., alum for cotton dyeing).

- Tannins: Create hydrogen bonds with the fiber, increasing dye retention (e.g., oak gall tannins for wool dyeing).

- Synthetic mordants: Developed to provide specific properties, such as improved wash fastness or color depth.

7. Describe the different types of dyeing machines and their applications?

Dyeing machines vary in design and are chosen based on fabric type, dye properties, and production volume:

- Batch dyeing machines: Used for small to medium batches, allowing for precise dye penetration.

- Continuous dyeing machines: Suitable for large-scale production, providing consistent dyeing results.

- Jet dyeing machines: High-speed machines that use pressurized dye solutions to achieve rapid penetration.

- Pad dyeing machines: Used for applying dyes to fabrics in a continuous manner, suitable for lightweight fabrics.

8. What are the environmental concerns associated with dyeing and how can they be mitigated?

Dyeing can potentially impact the environment:

- Water pollution: Dye effluents can contain chemicals that harm aquatic life.

- Air pollution: Volatile organic compounds (VOCs) emitted during dyeing can contribute to smog.

- Waste generation: Dyeing processes generate solid and hazardous waste.

Mitigating measures include:

- Using eco-friendly dyes and auxiliaries.

- Implementing wastewater treatment systems.

- Recycling and reducing waste.

- Adopting sustainable dyeing techniques.

9. Explain the importance of quality control in dyeing and how it is maintained?

Quality control ensures consistency and adherence to specifications in the dyeing process:

- Raw material testing: Evaluating dyes, chemicals, and fabrics before use.

- Color matching and measurement: Verifying that the dyed fabric meets the desired shade.

- Fastness testing: Ensuring the dyed fabric maintains its color under various conditions.

- Recordkeeping and documentation: Maintains traceability and accountability.

- Regular audits and calibration: Monitoring equipment and processes for accuracy and precision.

10. Describe the safety precautions that should be followed in a dye-house?

Dye-houses involve potential hazards:

- Chemical exposure: Wear proper protective gear (e.g., gloves, masks, goggles) and handle chemicals safely.

- Equipment operation: Use machinery correctly and follow safety protocols to prevent accidents.

- Fire safety: Store flammable materials appropriately and have fire extinguishers readily available.

- Ventilation: Ensure adequate ventilation to avoid inhalation of fumes and vapors.

- Emergency procedures: Know and practice emergency procedures in case of spills, fires, or medical emergencies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dye-House Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dye-House Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dye-house Workers are responsible for the dyeing of fabrics and other materials. They must be familiar with various dyeing techniques, and be able to operate dyeing machines.Dye-house Workers typically perform the following tasks:

Fabric Preparation

Dye-house Workers prepare fabrics for dyeing by scouring, bleaching, and mercerizing. They must also ensure that the fabrics are properly prepared before entering the dyeing machine.

- Scouring removes dirt and other impurities from the fabric.

- Bleaching whitens the fabric and removes any remaining impurities.

- Mercerizing strengthens the fabric and makes it more receptive to dyes.

Dyeing

Dye-house Workers dye fabrics using a variety of techniques, including immersion dyeing, pad dyeing, and jet dyeing. They must be able to control the temperature, pH, and other factors to ensure that the fabric is dyed evenly.

- Immersion dyeing involves submerging the fabric in a dye bath.

- Pad dyeing involves passing the fabric through a dye pad.

- Jet dyeing involves spraying the fabric with a dye solution.

Finishing

Dye-house Workers finish the dyed fabrics by rinsing, drying, and pressing them. They must ensure that the fabrics are properly finished before being sent to the customer.

- Rinsing removes any excess dye from the fabric.

- Drying removes any moisture from the fabric.

- Pressing smooths the fabric and gives it a finished appearance.

Interview Tips

Preparing for an interview for a Dye-house Worker position can be daunting, but with the right preparation, you can increase your chances of success.

Research the Company

Take some time to research the company you’re applying to. This will help you understand their culture, values, and what they’re looking for in a Dye-house Worker.

Practice Answering Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice answering these questions in advance so that you can deliver confident and well-thought-out responses.

Highlight Your Skills and Experience

Be sure to highlight your skills and experience that are relevant to the job. For example, if you have experience operating dyeing machines, be sure to mention this in your interview.

Be Enthusiastic and Positive

Dye-house Workers are often responsible for working in a fast-paced environment. Be sure to demonstrate your enthusiasm for the job and your ability to work well under pressure.

Next Step:

Now that you’re armed with the knowledge of Dye-House Worker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Dye-House Worker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini