Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dye Lab Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dye Lab Technician so you can tailor your answers to impress potential employers.

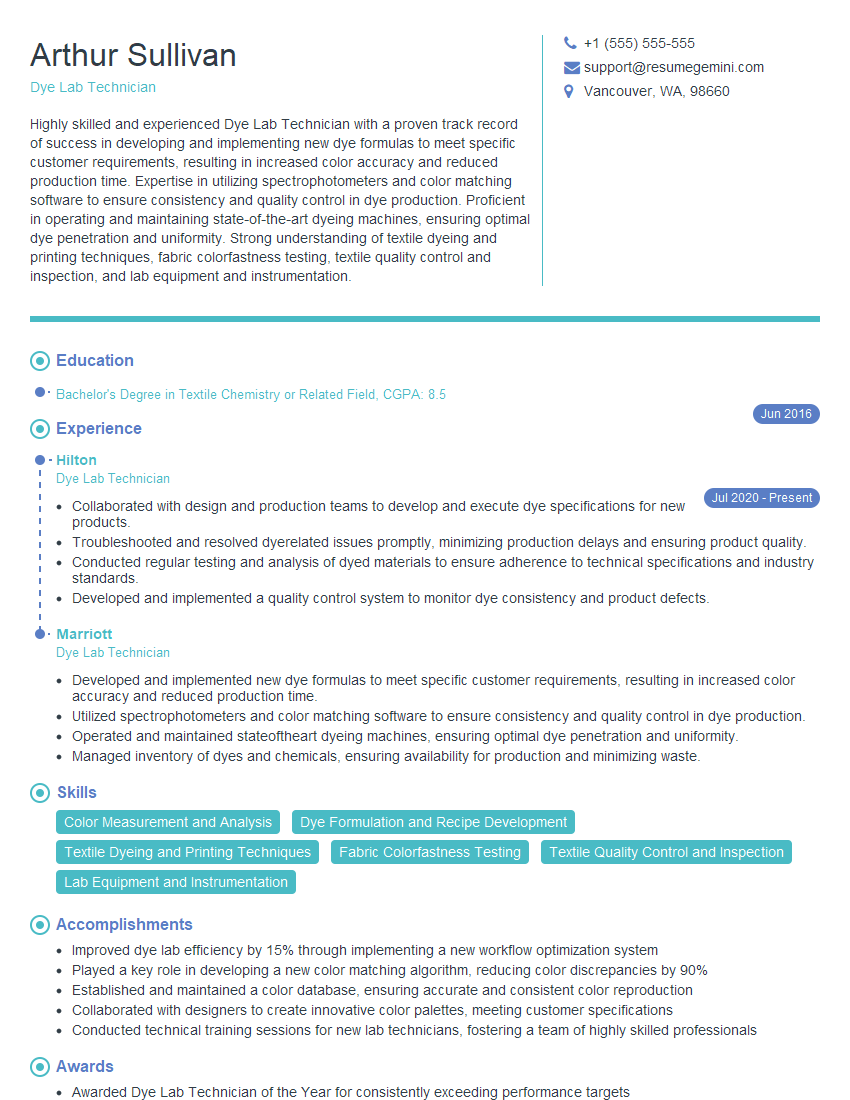

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dye Lab Technician

1. Explain the steps involved in conducting a dye test on a fabric sample?

In conducting a dye test on a fabric sample, here are the key steps involved:

- Sample Preparation: The fabric sample is prepared by cutting a small piece and cleaning it to remove any impurities.

- Dye Application: The sample is then immersed in a dye solution of the desired color. The temperature, pH, and duration of immersion are carefully controlled to ensure proper dye absorption.

- Rinsing and Drying: After dyeing, the sample is rinsed thoroughly with water to remove excess dye. It is then dried under controlled conditions to prevent color fading or distortion.

- Color Assessment: The dyed sample is evaluated for colorfastness, shade, and uniformity using spectrophotometers or visual assessment against a standard.

- Documentation and Reporting: The results of the dye test are recorded, including the dye used, dyeing conditions, and the color assessment data.

2. What are the different types of dyes used in the textile industry and their properties?

Natural Dyes

- Derived from plants, animals, or minerals

- Biodegradable and environmentally friendly

- Limited color range and lower colorfastness

Synthetic Dyes

- Man-made dyes with a wide range of colors

- Excellent colorfastness and durability

- Can be more expensive and potentially harmful to the environment

Reactive Dyes

- Form strong covalent bonds with cellulose fibers

- Produce bright and wash-resistant colors

- Used for dyeing cotton, rayon, and other cellulosic fibers

Disperse Dyes

- Dye synthetic fibers such as polyester and nylon

- Create vibrant colors and are resistant to fading

- Do not chemically bond to the fibers, but are held in place by physical forces

3. How do you control the color accuracy and consistency in the dyeing process?

To control color accuracy and consistency in the dyeing process, several measures are taken:

- Standardized Dye Recipes: Precise dye recipes are developed and followed to ensure consistent color results.

- Color Matching Tools: Spectrophotometers or colorimeters are used to measure and match colors accurately.

- Process Control: Temperature, pH, and duration of dyeing are carefully monitored and controlled to ensure optimal dye absorption and color development.

- Sample Testing: Regular testing of dyed samples is conducted to verify color accuracy and consistency. Adjustments are made as needed.

- Operator Training: Dyers are trained on color theory, dyeing techniques, and quality control procedures to ensure adherence to standards.

4. What are the common defects that can occur in the dyeing process and how do you prevent them?

Common dyeing defects and preventive measures:

- Uneven Dyeing: Caused by uneven distribution of dye or fabric tension. Prevention: Proper mixing, even fabric preparation, and tension control.

- Color Bleeding: Excess dye not properly fixed. Prevention: Adequate rinsing, use of dye fixatives, and appropriate drying conditions.

- Fading: Loss of color over time due to light, heat, or washing. Prevention: Use of lightfast and washfast dyes, controlled drying conditions.

- Staining: Dye transfer from one fabric to another. Prevention: Adequate rinsing, use of anti-staining agents, and proper separation of fabrics.

- Crocking: Color transfer from dyed fabric to other surfaces. Prevention: Use of crock-resistant dyes, proper rinsing, and testing before use.

5. How do you handle and store dyes and chemicals safely?

- Proper Storage: Store dyes and chemicals in appropriate containers, in a well-ventilated area, away from direct sunlight.

- PPE: Wear personal protective equipment (gloves, mask, apron) when handling and using dyes.

- Spill Handling: In case of spills, follow safety protocols, contain the spill, and clean up promptly.

- Waste Disposal: Dispose of dyes and chemicals according to local and environmental regulations.

- Training: Ensure proper training for staff on safe handling and disposal practices.

6. What quality control procedures do you implement to ensure the quality of dyed fabrics?

- Visual Inspection: Regular visual inspection of dyed fabrics for defects, evenness, and color accuracy.

- Lab Testing: Conduct laboratory tests to assess colorfastness, lightfastness, and washfastness.

- Customer Feedback: Monitor customer feedback and address any quality concerns promptly.

- Continuous Improvement: Regularly review and improve quality control processes to maintain high standards.

- Documentation: Maintain records of all quality control tests and procedures for traceability and accountability.

7. How do you stay updated with the latest advancements in dyeing technology and best practices?

- Industry Publications: Read industry magazines, journals, and online resources.

- Conferences and Exhibitions: Attend industry events to learn about new technologies and innovations.

- Training and Workshops: Participate in training and workshops offered by equipment manufacturers and industry experts.

- Networking: Connect with colleagues and professionals in the field to exchange knowledge and stay informed about emerging trends.

- Research and Development: Engage in research and development activities to explore new dyeing techniques and improve processes.

8. What are the environmental considerations in the dyeing process and how do you address them?

- Wastewater Treatment: Use of efficient wastewater treatment systems to minimize water pollution.

- Dye Selection: Opting for eco-friendly and biodegradable dyes to reduce environmental impact.

- Energy Conservation: Employing energy-efficient dyeing equipment and optimizing dyeing processes.

- Waste Reduction: Implementing measures to minimize waste generation, such as recycling and reuse.

- Compliance: Adhering to environmental regulations and industry standards.

9. How do you manage a team of dyers and ensure productivity and quality?

- Clear Communication: Establishing clear communication channels and expectations for the team.

- Training and Support: Providing ongoing training and support to enhance team skills and knowledge.

- Performance Monitoring: Regularly assessing and monitoring team performance to identify areas for improvement.

- Continuous Improvement: Encouraging team involvement in continuous improvement initiatives to optimize processes.

- Recognition and Motivation: Recognizing and rewarding team contributions to maintain motivation and productivity.

10. Describe a challenging dyeing project you worked on and how you overcame the obstacles.

Example: “In a recent project, we encountered an issue with color fading on a particular fabric. Through thorough investigation and experimentation, we discovered that the dye used was not compatible with the fabric’s composition. We then researched and tested alternative dyes and identified a suitable option that provided the desired colorfastness without compromising the fabric’s quality.”Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dye Lab Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dye Lab Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dye Lab Technicians are responsible for conducting a variety of tests and experiments on dyes and fabrics in order to ensure that they meet quality standards. They may also be responsible for developing new dyeing techniques and processes.

1. Conduct Tests and Experiments

Dye Lab Technicians conduct a variety of tests and experiments on dyes and fabrics. These tests may include:

- Colorfastness tests to ensure that the dye will not fade or bleed when washed or exposed to sunlight

- Lightfastness tests to ensure that the dye will not fade when exposed to light

- pH tests to ensure that the dye is compatible with the fabric

- Tensile strength tests to ensure that the fabric is strong enough to withstand the dyeing process

2. Develop New Dyeing Techniques and Processes

Dye Lab Technicians may also be responsible for developing new dyeing techniques and processes. This may involve experimenting with different dyes, fabrics, and dyeing methods. Dye Lab Technicians may also work with engineers and other scientists to develop new dyeing equipment.

3. Maintain Equipment

Dye Lab Technicians are responsible for maintaining the equipment in the dye lab. This may include cleaning and calibrating equipment, as well as troubleshooting and repairing any problems.

4. Keep Records

Dye Lab Technicians are responsible for keeping records of all tests and experiments that they conduct. These records may be used to track the progress of dyeing projects, as well as to troubleshoot any problems that may occur.

Interview Tips

Preparing for an interview can be nerve-wracking, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company

Before you go on an interview, it’s important to do your research on the company. This will help you learn more about the company’s culture, values, and goals. You can also use this information to tailor your answers to the interviewer’s questions.

2. Practice Your Answers

Once you’ve done your research, it’s time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you’re applying for.

4. Be on Time

Punctuality is important, so make sure you arrive for your interview on time. If you’re running late, call the interviewer and let them know.

5. Be Yourself

The most important tip is to be yourself. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

6. Ask Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your chance to learn more about the job and the company. It’s also a good way to show the interviewer that you’re interested in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dye Lab Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!