Are you gearing up for an interview for a Dye Tub Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Dye Tub Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

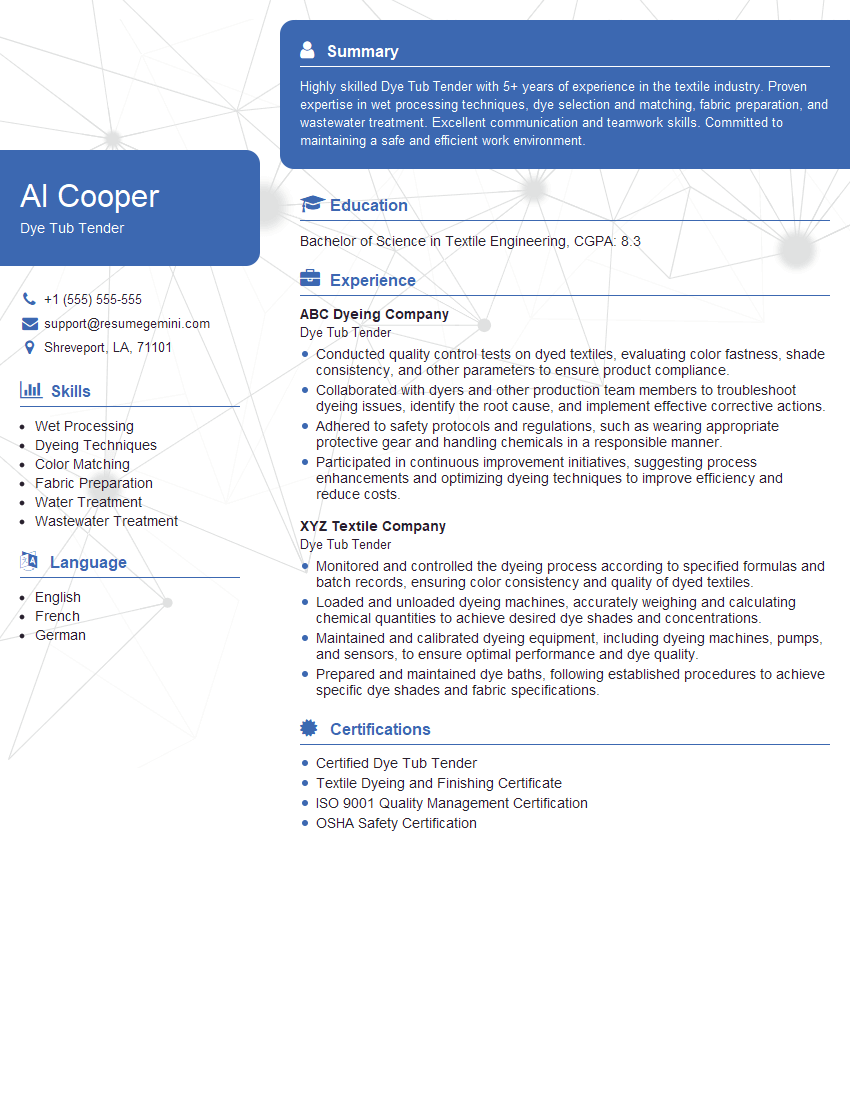

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dye Tub Tender

1. Describe the key responsibilities of a Dye Tub Tender in the textile industry?

As a Dye Tub Tender, my primary responsibilities would be to ensure efficient and accurate dyeing processes within the textile industry. Key tasks include:

- Loading and unloading dye tubs with fabrics or yarns

- Monitoring dye concentrations, pH levels, and temperature during the dyeing process

- Controlling and adjusting machine settings to achieve desired color and shade

- Maintaining a clean and safe work environment

- Following established dye recipes and quality control procedures

2. Explain the different types of dyeing methods used in the textile industry and their advantages and disadvantages?

Batch Dyeing

- Advantages: Simple process, suitable for small batches

- Disadvantages: Variation in color uniformity, higher water consumption

Continuous Dyeing

- Advantages: High production rates, consistent color

- Disadvantages: High equipment cost, unsuitable for small batches

Yarn Dyeing

- Advantages: Color fastness, less shrinkage

- Disadvantages: Slower process, higher cost

Garment Dyeing

- Advantages: Reduces inventory, allows for customization

- Disadvantages: Possibility of shading variations, fabric shrinkage

3. What are the critical factors to consider when determining the dye concentration for a specific fabric?

Determining the dye concentration requires consideration of several factors:

- Fabric type and fiber content: Different fibers exhibit different affinities for dyes

- Desired color and shade: The amount of dye used directly impacts the color intensity

- Dyeing method: Batch dyeing requires higher dye concentrations compared to continuous dyeing

- Water quality: Impurities in water can affect dye absorption

- Equipment capacity: The size of the dye tub and fabric load influences dye concentration

4. Describe the importance of pH control during the dyeing process and how it affects the color outcome?

pH control is crucial in dyeing as it influences dye absorption, colorfastness, and shade consistency. Maintaining the appropriate pH:

- Enhances dye absorption: Optimal pH levels allow dyes to penetrate the fabric more effectively

- Improves colorfastness: Correct pH prevents color migration and fading

- Ensures shade consistency: pH variations can result in uneven dye absorption, leading to shade variations

5. What are the common defects that can occur during the dyeing process and how can they be prevented?

Dyeing defects include:

- Uneven dyeing: Caused by improper dye distribution, uneven fabric tension, or inadequate mixing

- Color bleeding: Occurs when dye transfers from one fiber to another due to poor dye fixation

- Shading: Variation in color between different areas of the fabric, resulting from uneven dye penetration

- Spots or streaks: Caused by foreign particles or improper dye bath circulation

Prevention measures include:

- Proper fabric preparation

- Accurate dye mixing and distribution

- Optimal pH and temperature control

- Regular equipment maintenance

6. Describe the use of color matching systems in the dyeing industry and their benefits?

Color matching systems are essential for:

- Reproducing specific colors: Matching existing shades or creating new ones accurately

- Quality control: Ensures consistency in color across different batches

- Reducing dye waste: Optimizes dye usage by calculating precise amounts required

7. What are the safety precautions that must be observed when working with dyes and chemicals in the dyeing process?

Safety measures include:

- Wearing appropriate personal protective equipment

- Maintaining a clean and well-ventilated work environment

- Proper handling and storage of chemicals

- Regular safety training and awareness programs

- Adhering to established safety protocols

8. Explain the role of automation in modern dyeing processes and its advantages?

Automation in dyeing brings several advantages:

- Improved efficiency: Automated systems optimize dye mixing, dispensing, and temperature control

- Enhanced color consistency: Precise control reduces variability and ensures consistent shades

- Increased productivity: Automation reduces manual labor, allowing for higher production rates

- Reduced environmental impact: Automated systems minimize water and energy consumption

9. How do you stay updated with the latest trends and innovations in the dyeing industry?

I keep myself updated by:

- Reading industry publications and attending trade shows

- Participating in workshops and training sessions

- Networking with industry professionals and attending conferences

- Exploring online resources and research papers

10. What are your strengths and weaknesses as a Dye Tub Tender?

My strengths include:

- Expertise in dye mixing and color matching

- Strong understanding of dyeing principles and chemistry

- Attention to detail and accuracy

- Ability to work independently and as part of a team

Areas for improvement:

- Expanding knowledge of automated dyeing systems

- Improving time management skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dye Tub Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dye Tub Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dye Tub Tenders are responsible for overseeing the dyeing process in textile manufacturing. Their primary duties include preparing and maintaining dye baths, operating dyeing equipment, and inspecting dyed fabrics for quality. Below are some of the key responsibilities:

1. Dye Bath Preparation and Maintenance

Preparing and maintaining dye baths is a critical task for Dye Tub Tenders. They must ensure that the dye baths are properly formulated, in accordance to the fabric specification, and maintained at the correct temperature and pH level.

- Weigh and measure dye and chemical ingredients according to specified dye formulations.

- Add chemicals to water and mix thoroughly to create dye bath.

- Monitor dye bath temperature and pH level and make adjustments as needed.

- Maintain dye bath cleanliness and prevent contamination.

2. Dyeing Operation

Dye Tub Tenders operate dyeing equipment to dye fabrics according to specified colours and shades. They must follow established procedures and adhere to safety regulations.

- Load fabric into dyeing machine.

- Operate dyeing machine to dye fabric.

- Control dyeing time, temperature, and pressure.

- Unload dyed fabric from dyeing machine.

3. Dyed Fabric Inspection

Dye Tub Tenders inspect dyed fabrics to ensure that they meet quality standards. They examine the fabric for evenness of colour, shade, and any defects.

- Inspect dyed fabric for colour accuracy, shade, and uniformity.

- Identify and mark any defects, such as uneven dyeing, stains, or holes.

- Document inspection results and report any quality issues.

4. Equipment Maintenance and Troubleshooting

Dye Tub Tenders are responsible for maintaining and troubleshooting dyeing equipment. They must keep the equipment clean, lubricated, and in good working order.

- Clean and lubricate dyeing equipment.

- Inspect equipment for wear and tear.

- Identify and resolve equipment malfunctions.

- Follow established maintenance schedules.

Interview Tips

Preparing for a Dye Tub Tender interview requires understanding the key responsibilities of the role and researching the company. Here are some tips to help you ace the interview:

1. Research the role

Before the interview, take the time to research the specific role and the company you are applying to. This will help you understand the company’s culture, the specific responsibilities of the Dye Tub Tender role, and the qualifications they are looking for. You can find this information on the company’s website or by reading industry publications.

- Visit the company website to learn about their products, services, and culture.

- Read industry publications to stay up-to-date on the latest trends and technologies in textile dyeing.

- Check LinkedIn to see if you have any connections who work at the company.

2. Practice your answers

Once you have a good understanding of the role and the company, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Think about your experience and qualifications, and how they relate to the job requirements.

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?”

- Practice your answers out loud so that you can deliver them smoothly and confidently.

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office setting. You should also avoid wearing strong scents or jewellery that could be distracting.

4. Be on time

Punctuality is important, so make sure to arrive for your interview on time. If you’re running late, be sure to call or email the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be honest, confident, and enthusiastic, and you’ll be sure to make a great impression.

- Be honest and genuine in your answers.

- Show your enthusiasm for the role and the company.

- Ask questions to show that you’re interested and engaged.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Dye Tub Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Dye Tub Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.