Are you gearing up for a career in Dynamic Balancer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dynamic Balancer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

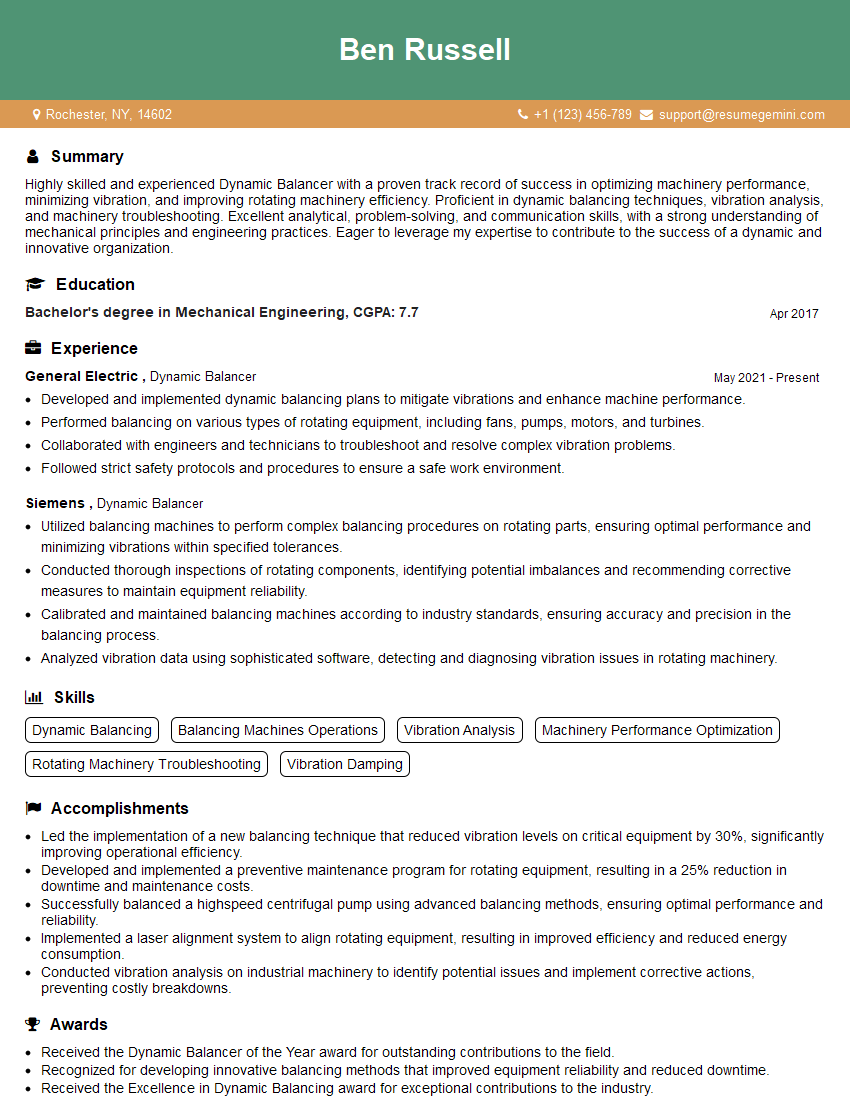

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dynamic Balancer

1. How do you ensure that the dynamic balancing machine is properly calibrated and maintained?

- Perform regular calibration checks using standard test rotors.

- Follow the manufacturer’s recommended maintenance schedule, including cleaning, lubrication, and component replacement.

- Keep a detailed maintenance log to track all calibration and maintenance activities.

- Monitor machine performance and make adjustments as necessary to maintain accuracy.

- Stay up-to-date on industry best practices and advancements in dynamic balancing technology.

2. What are the different types of dynamic balancing machines, and how do you choose the appropriate machine for a specific application?

Factors to consider when choosing a dynamic balancing machine:

- Size and weight of the rotor to be balanced.

- Required accuracy and speed range.

- Type of unbalance (static or dynamic).

- Budget and space constraints.

Types of dynamic balancing machines:

- Hard bearing machines: Use fixed bearings to support the rotor.

- Soft bearing machines: Use flexible bearings to support the rotor.

- Vertical machines: Orient the rotor vertically.

- Horizontal machines: Orient the rotor horizontally.

3. How do you interpret the results of a dynamic balancing test and determine the necessary corrective actions?

- Examine the unbalance amplitude and phase readings.

- Identify the location and magnitude of the unbalance.

- Determine the appropriate corrective action (e.g., adding or removing weight, adjusting the rotor geometry).

- Verify the effectiveness of the corrective action by performing a post-correction balance test.

4. What is the difference between static and dynamic balancing, and when is each type of balancing required?

- Static balancing: Corrects for imbalances that occur when the rotor is stationary.

- Dynamic balancing: Corrects for imbalances that occur when the rotor is rotating.

- Dynamic balancing is required when:

- The rotor operates at high speeds.

- The rotor is flexible.

- The unbalance is distributed along the length of the rotor.

5. What are the potential consequences of improper dynamic balancing, and how can they be mitigated?

- Potential consequences:

- Excessive vibration

- Bearing failure

- Reduced machine life

- Safety hazards

- Mitigation:

- Properly calibrate and maintain the dynamic balancing machine.

- Choose the appropriate balancing machine for the application.

- Interpret the test results accurately and determine the necessary corrective actions.

- Verify the effectiveness of the corrective actions.

- Establish a regular maintenance program to monitor and maintain balance over time.

6. How do you handle situations where a rotor cannot be balanced within the specified tolerances?

- Investigate the cause of the excessive unbalance.

- Consider alternative balancing methods (e.g., modal balancing, field balancing).

- Consult with the equipment manufacturer or a specialist for guidance.

- Document the situation and any corrective actions taken.

7. What are the latest advancements in dynamic balancing technology, and how do they impact your work?

- Advancements:

- Laser-based measurement systems

- Automated balancing machines

- Wireless data transmission

- Predictive maintenance techniques

- Impact on work:

- Improved accuracy and efficiency

- Reduced downtime

- Enhanced safety

- Increased productivity

8. How do you stay up-to-date on industry best practices and advancements in dynamic balancing?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and discussion groups.

- Consult with equipment manufacturers and balancing specialists.

- Engage in continuous professional development.

9. What are the key challenges you have faced in your previous role as a Dynamic Balancer, and how did you overcome them?

- Challenge: Balancing a large, complex rotor with tight tolerance requirements.

- Solution: Collaborated with engineers to design a custom balancing setup and developed an innovative balancing procedure.

- Challenge: Troubleshooting an intermittent vibration issue on a critical machine.

- Solution: Performed extensive data analysis and dynamic testing to identify the root cause and implement a permanent fix.

10. How do you ensure that your dynamic balancing work meets the highest quality standards and customer expectations?

- Adhere to established quality control procedures.

- Use calibrated and certified equipment.

- Follow manufacturer’s guidelines and industry best practices.

- Document all balancing activities and provide detailed reports to customers.

- Seek feedback and continuously improve processes to enhance quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dynamic Balancer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dynamic Balancer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dynamic Balancers are experts in balancing rotating equipment to minimize vibrations and noise.

### 1. Equipment BalancingDynamic Balancers are responsible for balancing a wide range of rotating equipment, including fans, pumps, motors, and turbines.

- Identify and locate the source of imbalance in rotating equipment using specialized balancing instruments, such as vibration analyzers and laser alignment systems.

- Perform dynamic balancing procedures to correct imbalances and minimize vibrations, ensuring smooth and efficient operation of equipment.

Dynamic Balancers analyze vibration data to assess the health of rotating equipment and identify potential issues.

- Monitor and record vibration levels using vibration analyzers and other diagnostic tools.

- Interpret vibration data to identify potential problems with equipment, such as misalignment, bearing issues, or imbalances.

Dynamic Balancers contribute to the overall maintenance and troubleshooting of rotating equipment to ensure optimal performance.

- Inspect equipment for signs of wear or damage, including bearings, shafts, and other components.

- Provide recommendations for repairs or replacements based on vibration analysis and maintenance history.

Dynamic Balancers often interact with customers and provide support and documentation to ensure understanding and satisfaction.

- Communicate with customers to explain balancing procedures, vibration analysis results, and maintenance recommendations.

- Prepare detailed reports and documentation to record balancing and vibration analysis findings, providing visibility and traceability of the work performed.

Interview Tips

Preparing for an interview for a Dynamic Balancer position requires a combination of technical knowledge and communication skills. Here are some tips to help you ace the interview:

### 1. Research the Company and IndustryFamiliarize yourself with the company’s background, industry experience, and the specific role you are applying for. This shows that you are genuinely interested in the position and have taken the time to understand the context.

### 2. Highlight Relevant Skills and ExperienceEmphasize your expertise in dynamic balancing, vibration analysis, and equipment maintenance. Provide specific examples of your work, quantifying your accomplishments whenever possible.

### 3. Demonstrate Problem-Solving AbilitiesInterviewers often ask situational questions to assess your problem-solving skills. Prepare anecdotes from previous experiences where you identified and resolved issues related to rotating equipment.

### 4. Showcase Communication SkillsDynamic Balancers interact with customers and colleagues frequently. Showcase your effective communication skills by clearly explaining technical concepts and conveying recommendations with confidence.

### 5. Prepare QuestionsAsking well-thought-out questions demonstrates your interest and engagement. Prepare questions about the company’s approach to equipment maintenance, industry best practices, or specific projects you may be involved in.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dynamic Balancer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.