Are you gearing up for an interview for a Edge Bonder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Edge Bonder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

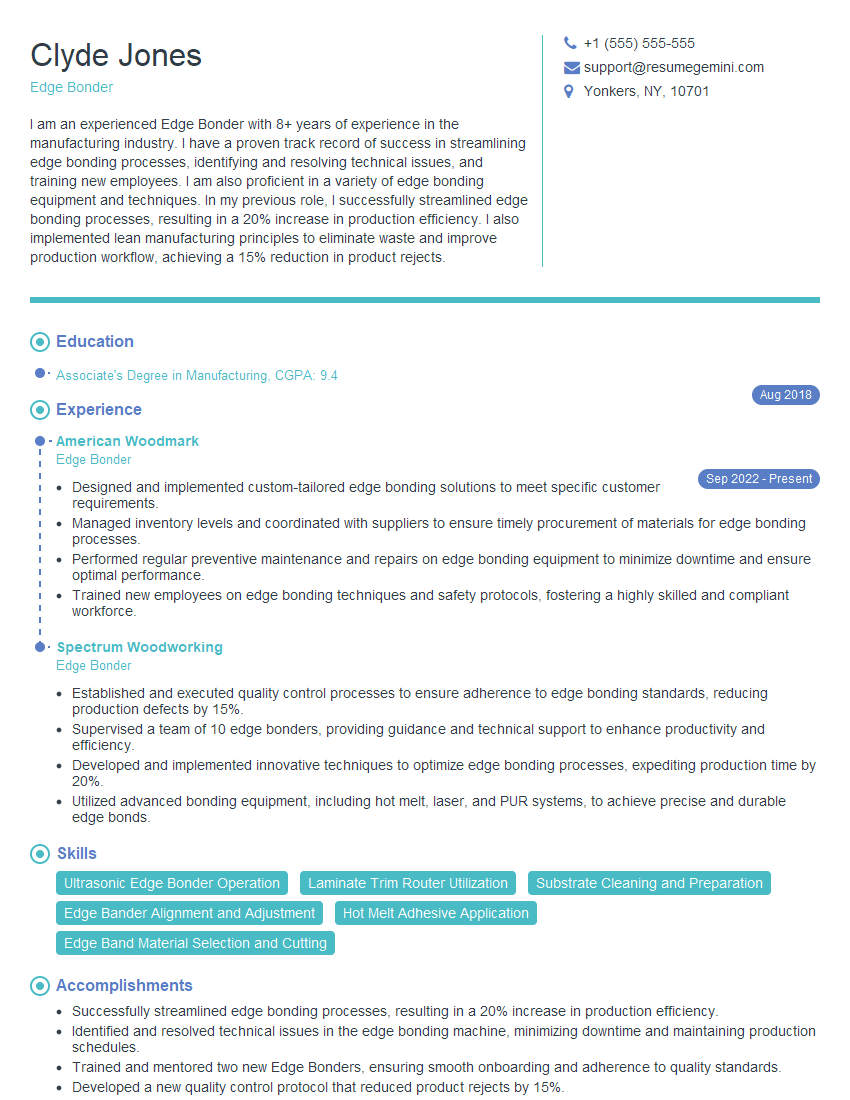

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Edge Bonder

1. Describe the key functions of an Edge Bonder?

- Bonds edges of two or more panels using heat and adhesive tape

- Applies glue to the edges of the panels

- Heat-activates the adhesive

- Joins and cures the panels together

- Trims the excess adhesive

2. What are the different types of Edge Bonders?

Manual Edge Bonders

- Require manual positioning and operation

- Suitable for small production runs and prototypes

Semi-Automatic Edge Bonders

- Automated panel loading and unloading

- Manual positioning and activation

- Higher efficiency than manual edge bonders

Fully Automatic Edge Bonders

- Fully automated process, including panel loading, positioning, bonding, curing, and trimming

- Highest efficiency and productivity

3. What are the key considerations when selecting an Edge Bonder?

- Production volume and requirements

- Types of materials being bonded

- Desired bond strength and quality

- Available space and budget

- Manufacturer reputation and technical support

4. What are the safety precautions that need to be observed when operating an Edge Bonder?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and earplugs

- Ensure proper ventilation to prevent exposure to fumes

- Keep work area clean and free of debris

- Follow manufacturer’s instructions for safe operation and maintenance

- Be aware of moving parts and potential pinch points

5. Describe the process of edge bonding two panels using a manual Edge Bonder?

- Prepare the edges of the panels by cleaning and removing any dust or debris

- Apply adhesive tape or glue to the edges of the panels

- Place the panels in the edge bonding machine and align them properly

- Activate the heating element to heat the adhesive

- Apply pressure to join the panels together and cure the adhesive

- Trim the excess adhesive and inspect the bond

6. What are the common challenges encountered in edge bonding and how can they be resolved?

Gaps or misalignment:

- Ensure proper alignment and positioning of the panels

- Use fixtures or guides to hold the panels in place

Weak bonds:

- Check the adhesive type and ensure it is suitable for the materials being bonded

- Apply the adhesive evenly and use the appropriate amount

- Properly heat and cure the adhesive

Excess adhesive:

- Apply the adhesive sparingly

- Use a cutter or trimmer to remove excess adhesive

7. Describe the role of adhesive selection in edge bonding?

- Adhesive type should match the materials being bonded and the intended application

- Consider factors such as bond strength, viscosity, open time, and temperature resistance

- Test different adhesives to determine the most suitable for the specific bonding needs

8. How do you calibrate and maintain an Edge Bonder?

- Follow manufacturer’s instructions for calibration and maintenance

- Calibrate the temperature and pressure settings regularly

- Clean and lubricate all moving parts

- Inspect the machine for any signs of wear or damage

9. Describe the importance of jig and fixture design in edge bonding?

- Jigs and fixtures ensure precise alignment and positioning of panels

- They minimize gaps and misalignments, resulting in stronger and more consistent bonds

- Proper jig and fixture design can improve productivity and reduce rework

10. What are some innovative technologies and trends in edge bonding?

- Laser edge bonding: Uses laser technology to heat and activate the adhesive

- Ultrasonic edge bonding: Uses ultrasonic vibrations to create a strong and durable bond

- Automated edge bonding systems: Offer high efficiency and precision

- Environmentally friendly adhesives: Reduce VOC emissions and improve sustainability

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Edge Bonder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Edge Bonder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Edge Bonder is responsible for a range of tasks involving the bonding of materials, typically in furniture, cabinetry, and construction. Their key responsibilities include:

1. Edge Banding

Operating edge banding machines to apply materials such as veneer, melamine, or PVC to edges of substrates like wood, MDF, or plywood.

2. Quality Control

Inspecting bonded edges for quality, ensuring proper adhesion, alignment, and finish.

3. Troubleshooting and Maintenance

Identifying and resolving issues with edge banding machines, performing routine maintenance to ensure optimal performance.

4. Safety Protocols

Adhering to safety regulations and operating machines safely, utilizing proper personal protective equipment (PPE).

5. Raw Material Management

Monitoring and maintaining inventory of edge banding materials, ensuring availability for production.

6. Communication and Collaboration

Communicating with production team members, understanding project requirements, and providing updates on progress.

Interview Tips

To prepare effectively for an Edge Bonder interview, candidates should consider the following tips:

1. Research the Industry and Company

Demonstrate knowledge of the edge banding industry, including trends, equipment, and materials.

2. Practice Technical Skills

Review edge banding techniques, troubleshooting methods, and safety protocols to showcase your practical abilities.

3. Highlight Relevant Experience

Emphasize your experience in operating edge banding machines, quality control, or related areas.

4. Prepare for Behavioral Questions

Be prepared to answer questions about your teamwork, problem-solving, and attention to detail.

5. Demonstrate Enthusiasm and Motivation

Convey your interest in edge banding and your eagerness to contribute to the team.

6. Ask Thoughtful Questions

During the interview, ask questions that demonstrate your engagement and curiosity.

7. Dress Professionally and Arrive on Time

Make a positive impression by dressing appropriately and being punctual.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Edge Bonder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Edge Bonder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.