Are you gearing up for a career in Edge Cutting Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Edge Cutting Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

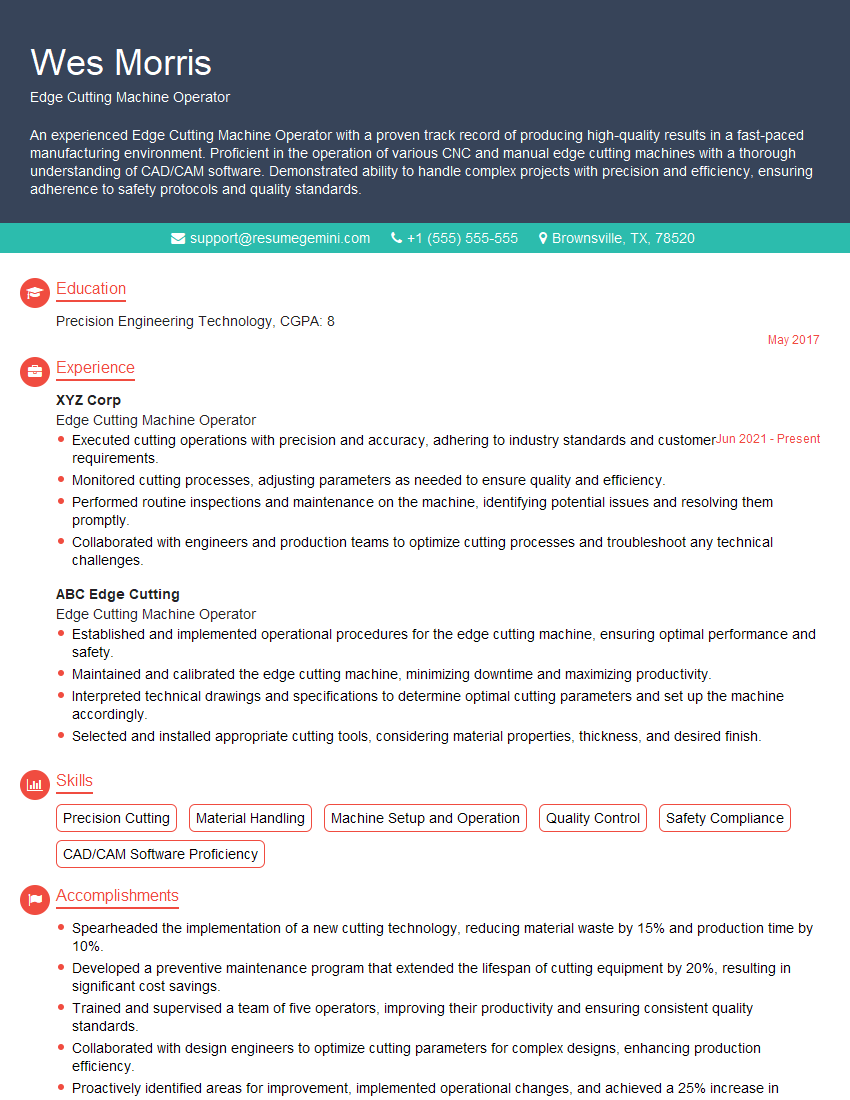

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Edge Cutting Machine Operator

1. What are the key responsibilities of an Edge Cutting Machine Operator?

As an Edge Cutting Machine Operator, my primary responsibilities entail:

- Operating and monitoring edge cutting machines to cut various materials precisely.

- Setting up and adjusting machine parameters to optimize cutting quality and efficiency.

2. Describe the different types of edge cutting machines you’ve worked with and their capabilities.

Throughout my experience, I have operated a range of edge cutting machines, including:

Waterjet Cutting Machines:

- Expertise in using waterjet technology to cut intricate shapes and designs.

- Proficient in programming and controlling cutting parameters to achieve precise results.

Laser Cutting Machines:

- Experienced in utilizing laser cutting technology to cut various materials with high accuracy and speed.

- Knowledge of laser cutting techniques and safety protocols.

Plasma Cutting Machines:

- Skilled in using plasma cutting technology to cut conductive materials with precision.

- Understanding of plasma cutting parameters and troubleshooting techniques.

3. How do you ensure the accuracy and precision of cut edges?

To guarantee the accuracy and precision of cut edges, I follow a meticulous process:

- Thoroughly inspect the material before cutting to identify any imperfections or defects.

- Program the machine precisely, considering material properties, cutting speed, and desired edge quality.

- Regularly calibrate and maintain cutting equipment to ensure optimal performance.

- Utilize measuring instruments to verify cut dimensions and ensure they meet specifications.

4. What are the common maintenance tasks required for edge cutting machines?

To maintain the optimal performance of edge cutting machines, I perform regular maintenance tasks:

- Clean and lubricate machine components, including cutting heads, nozzles, and guides.

- Inspect equipment for wear and tear, and replace or repair components as needed.

- Monitor fluid levels and ensure proper coolant and lubricant supply.

- Follow manufacturer’s recommended maintenance schedules and guidelines.

5. How do you handle discrepancies or errors during the cutting process?

When handling discrepancies or errors during the cutting process, I prioritize the following steps:

- Immediately stop the machine and identify the source of the error.

- Check cutting parameters, material properties, and machine settings.

- Inspect the cut material for defects or damage.

- Make necessary adjustments or repairs to rectify the error.

- Document the issue and corrective actions taken for future reference.

6. How do you prioritize multiple cutting orders and manage time effectively?

To effectively manage multiple cutting orders and time, I follow these strategies:

- Communicate with customers to establish clear priorities and deadlines.

- Plan cutting schedules strategically, considering machine availability, material requirements, and lead times.

- Prioritize urgent or critical orders, while ensuring timely completion of all orders.

- Utilize tools and techniques to optimize machine efficiency and reduce setup time.

- Monitor progress regularly and make adjustments to the schedule as needed.

7. What safety protocols do you observe when operating edge cutting machines?

Safety is paramount when operating edge cutting machines. I adhere to strict protocols, including:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Ensuring proper machine guarding and following lockout/tagout procedures during maintenance.

- Maintaining a clean and organized work area to prevent tripping or falling hazards.

- Receiving regular safety training and remaining updated on industry best practices.

- Reporting any safety concerns or incidents promptly.

8. How do you stay updated with advancements in edge cutting technology?

To stay abreast of advancements in edge cutting technology, I engage in the following activities:

- Attend industry conferences and workshops.

- Read technical publications and online resources.

- Network with other professionals in the field.

- Participate in training programs offered by equipment manufacturers.

- Explore new cutting techniques and applications.

9. Describe a challenging cutting project you successfully completed and the techniques you employed.

One challenging cutting project involved creating intricate cutouts in a thick metal sheet. I employed the following techniques:

- Utilized a high-powered laser cutting machine with a specialized nozzle to achieve precise and burr-free cuts.

- Programmed the machine with advanced nesting algorithms to optimize material utilization.

- Adjusted cutting parameters and utilized specialized cutting gases to ensure clean and accurate edge finishes.

- Implemented rigorous quality control measures to verify the accuracy and precision of the finished product.

10. How do you handle working in a fast-paced and demanding production environment?

In a fast-paced production environment, I thrive by implementing the following strategies:

- Maintaining a positive and proactive attitude under pressure.

- Prioritizing tasks effectively and managing time wisely.

- Collaborating with team members to ensure smooth workflow and meet deadlines.

- Continuously seeking ways to improve efficiency and optimize processes.

- Remaining calm and focused, even in challenging situations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Edge Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Edge Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Edge Cutting Machine Operators are responsible for operating and maintaining edge cutting machines, which are used to trim, shape, and finish the edges of various materials, including metal, plastic, and glass. They must have a thorough understanding of the machine’s operation and capabilities, as well as the ability to make adjustments to ensure precise and efficient cutting.

1. Machine Operation

The primary responsibility of an Edge Cutting Machine Operator is to operate the machine safely and efficiently. This includes loading and unloading materials, setting up the machine according to the required specifications, and monitoring the cutting process to ensure accuracy and quality.

- Load and unload materials, ensuring proper alignment and placement

- Configure machine settings based on material type, thickness, and desired edge finish

- Monitor cutting process, adjusting speed, feed rate, and other parameters as needed

2. Maintenance and Troubleshooting

To maintain optimal machine performance, operators are responsible for regular maintenance and troubleshooting. This may include cleaning and lubricating the machine, replacing worn or damaged parts, and diagnosing and resolving any operational issues that may arise.

- Perform regular cleaning and lubrication to prevent breakdowns and ensure precision

- Inspect machine components for wear or damage, and replace or repair as necessary

- Troubleshoot machine malfunctions, identifying the cause and implementing corrective actions

3. Quality Control

Ensuring the quality of the finished product is crucial. Operators are responsible for inspecting and measuring the cut edges to ensure they meet the required specifications. They may also make adjustments to the machine or cutting parameters to optimize the quality of the cut.

- Inspect cut edges for precision, accuracy, and surface finish

- Measure and verify dimensions to ensure compliance with specifications

- Identify and rectify any defects or inconsistencies in the cutting process

4. Safety and Compliance

Adhering to safety protocols and industry regulations is paramount. Operators must comply with all safety procedures, wear appropriate personal protective equipment (PPE), and maintain a clean and organized work area.

- Follow established safety guidelines and procedures to prevent accidents and injuries

- Wear appropriate PPE, such as safety glasses, gloves, and hearing protection

- Maintain a clean and organized work area to minimize hazards and improve efficiency

Interview Tips

To prepare for an interview for an Edge Cutting Machine Operator position, candidates should focus on showcasing their technical expertise, problem-solving abilities, and commitment to safety and quality.

1. Highlight Relevant Experience

Emphasize your experience in operating edge cutting machines, including the specific types of materials you have worked with and the processes you have used. Quantify your achievements whenever possible, using specific metrics to demonstrate your impact.

- Example: “In my previous role, I operated a CNC edge cutting machine to cut complex shapes in aluminum and stainless steel. I exceeded production targets by 15% while maintaining a high level of accuracy.”

2. Demonstrate Problem-Solving Skills

Interviewers will be interested in your ability to identify and resolve issues that may arise during the cutting process. Describe situations where you encountered challenges and how you used your technical knowledge and ingenuity to find solutions.

- Example: “During a production run, I noticed a slight variation in the edge quality. I analyzed the machine settings and identified a minor misalignment issue. By adjusting the alignment, I was able to restore the desired edge finish and minimize downtime.”

3. Emphasize Safety and Quality

Stress your commitment to safety and following proper operating procedures. Highlight your knowledge of industry regulations and your ability to maintain a clean and organized work area. Explain how you prioritize quality control and ensure that the finished edges meet the required specifications.

- Example: “I am committed to maintaining a safe work environment and adhering to all safety protocols. I regularly inspect the machine and PPE to ensure they are in good condition, and I always follow established procedures to minimize risks.”

4. Research the Company and Industry

Research the company and the industry to gain insights into their specific requirements and challenges. This will demonstrate your interest and enthusiasm for the role. Be prepared to discuss how your skills and experience align with the company’s needs.

- Example: “I am familiar with the company’s reputation for producing high-quality metal components, and I am eager to contribute my expertise in edge cutting to support your operations. I believe my experience in optimizing cutting parameters and ensuring precision will enable me to add value to your team.”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Edge Cutting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.