Feeling lost in a sea of interview questions? Landed that dream interview for Edge Molder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Edge Molder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

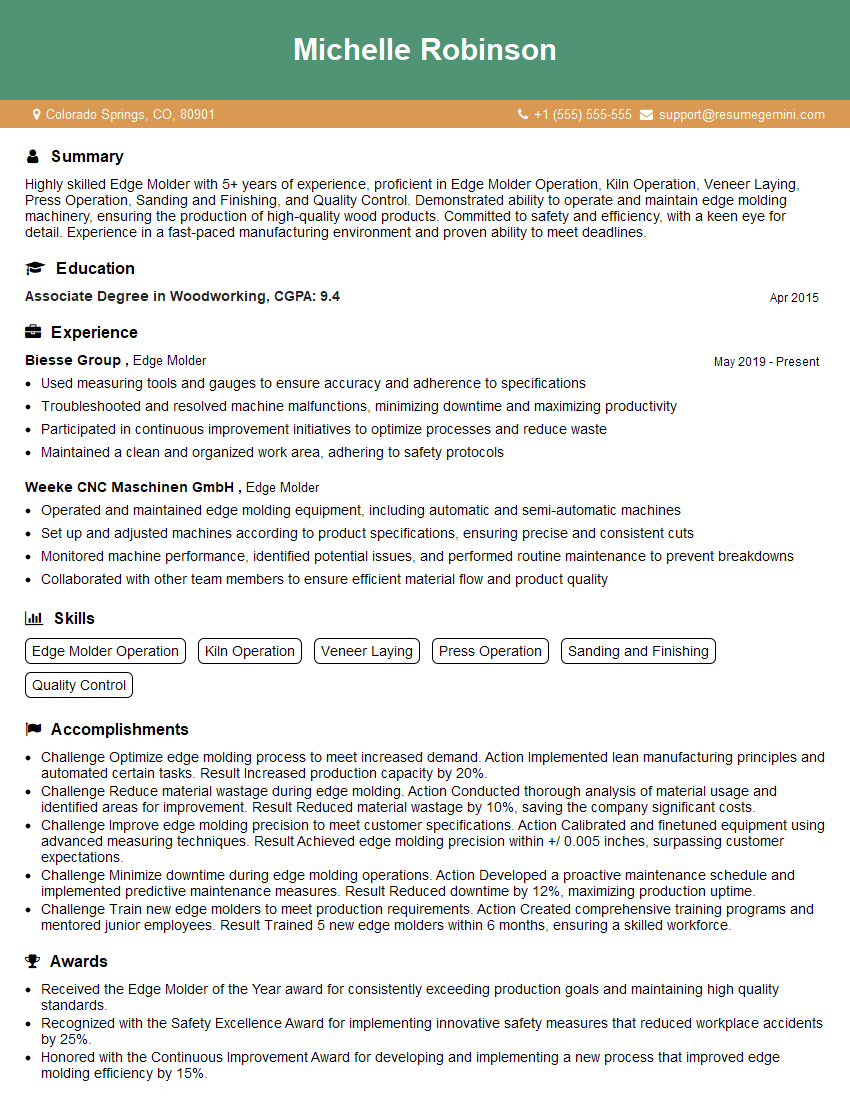

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Edge Molder

1. What are the key components of an edge molder and explain their functions?

- Feed motor: Drives the workpiece through the machine.

- Hold-down rollers: Keep the workpiece in place as it passes through the knives.

- Spindle: Rotates the knives.

- Knives: Cut the workpiece to the desired shape.

- Outfeed table: Supports the workpiece as it exits the machine.

2. How do you set up an edge molder for a specific profile?

Steps to set up an edge molder for a specific profile:

- Select the appropriate knives: Choose knives with the desired profile.

- Mount the knives on the spindle: Secure the knives to the spindle according to the manufacturer’s instructions.

- Adjust the hold-down rollers: Position the hold-down rollers to support the workpiece and prevent it from moving.

- Set the feed speed: Choose a feed speed that is appropriate for the workpiece material and profile.

- Test the setup: Run a test piece through the machine to ensure that the profile is correct.

Tips for setting up an edge molder:

- Use sharp knives: Dull knives can tear the workpiece and produce a poor-quality finish.

- Make sure the knives are properly aligned: Misaligned knives can cause the workpiece to be cut unevenly.

- Use a dust collection system: Dust can build up on the workpiece and knives, which can affect the quality of the cut.

3. How do you troubleshoot common problems with an edge molder?

- Workpiece is not cutting cleanly: Knives may be dull or misaligned. Check the knives and adjust accordingly.

- Workpiece is burning: Feed speed may be too slow. Increase the feed speed.

- Machine is vibrating excessively: Knives may be unbalanced. Check the knives and balance them accordingly.

4. What are the safety precautions that must be taken when operating an edge molder?

- Wear appropriate safety gear: Safety glasses, earplugs, and gloves should be worn when operating an edge molder.

- Keep hands away from the knives: Never reach into the machine while it is running.

- Secure the workpiece: The workpiece should be securely clamped to the table before starting the machine.

- Use a push stick: A push stick should be used to feed the workpiece through the machine.

- Maintain the machine: The edge molder should be inspected and maintained regularly to ensure that it is operating safely.

5. What are the different types of edge profiles that can be created with an edge molder?

- Bullnose: A rounded edge.

- Ogee: A curved edge with two different radii.

- Chamfer: A beveled edge.

- Cove: A concave edge.

- Miter: A 45-degree angle.

6. How do you achieve a smooth and consistent finish on an edge-molded workpiece?

- Use sharp knives: Dull knives can tear the workpiece and produce a rough finish.

- Make sure the knives are properly aligned: Misaligned knives can cause the workpiece to be cut unevenly.

- Use a light touch: Applying too much pressure to the workpiece can cause it to burn or tear.

- Feed the workpiece at a consistent speed: Feeding the workpiece too quickly or too slowly can produce an uneven finish.

7. How do you calculate the feed rate for an edge molder?

- Determine the desired surface speed: The surface speed is the speed at which the workpiece will be cut. It is typically measured in feet per minute (FPM).

- Calculate the spindle speed: The spindle speed is the speed at which the knives will rotate. It is calculated by dividing the surface speed by the circumference of the cutter.

- Calculate the feed rate: The feed rate is the speed at which the workpiece will be fed through the machine. It is calculated by multiplying the spindle speed by the number of teeth on the cutter.

8. What are the advantages of using an edge molder over other woodworking tools?

- Speed: Edge molders are much faster than hand-held tools, such as routers or sanders.

- Accuracy: Edge molders can produce precise and consistent cuts.

- Variety: Edge molders can be used to create a wide variety of edge profiles.

- Efficiency: Edge molders can be used to process large quantities of material quickly and efficiently.

9. What are the different ways to use an edge molder?

- Straight edging: Edge molders can be used to create straight edges on workpieces.

- Chamfering: Edge molders can be used to create beveled edges on workpieces.

- Profiling: Edge molders can be used to create a variety of edge profiles on workpieces.

- Dadoing: Edge molders can be used to create dados (grooves) in workpieces.

10. How do you maintain an edge molder?

- Clean the machine regularly: Remove sawdust and debris from the machine after each use.

- Lubricate the machine regularly: Lubricate all moving parts of the machine according to the manufacturer’s instructions.

- Inspect the knives regularly: Sharpen or replace the knives as needed.

- Calibrate the machine regularly: Calibrate the machine to ensure that it is cutting accurately.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Edge Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Edge Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Edge Molders are responsible for using specialized machinery and techniques to create decorative and functional edges on various materials, particularly wood. They ensure the smooth and precise formation of edges to enhance the aesthetic appeal and durability of products.The key job responsibilities of an Edge Molder include:

1. Machinery and Tool Handling

Operate a range of edge molding machines, including spindle and profile molders, to create intricate edge designs on wood and other materials.

- Select and install appropriate cutting tools, such as router bits and molding knives, based on the desired edge profile.

- Set up and adjust machine settings, including speed and feed rates, to achieve optimal cutting results.

2. Material Preparation and Processing

Prepare and process wood and other materials for edge molding, ensuring they meet specifications and are free from defects.

- Inspect raw materials for quality and select suitable pieces for edge molding.

- Cut and shape materials to the required dimensions and angles using saws and other cutting tools.

3. Edge Molding and Finishing

Use edge molding machines to create desired edge profiles on materials, maintaining precision and consistency.

- Monitor the molding process to ensure accurate and efficient cutting operations.

- Inspect the finished edges for quality, identifying and correcting any imperfections.

4. Quality Control and Maintenance

Maintain high standards of quality control throughout the edge molding process, ensuring the production of defect-free products.

- Regularly calibrate and maintain edge molding machines to ensure optimal performance and accuracy.

- Inspect finished products to verify conformity to specifications and customer requirements.

Interview Tips

Preparing for an interview for an Edge Molder position requires a combination of technical knowledge and effective communication skills. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Gain a comprehensive understanding of the company you’re applying to and the industry it operates in. This demonstrates your interest and preparedness.

- Visit the company’s website to learn about their products, services, and values.

- Research industry trends and best practices to show your knowledge of the field.

2. Highlight Your Skills and Experience

Tailor your resume and cover letter to the specific requirements of the Edge Molder position. Emphasize your relevant skills and experience.

- Quantify your accomplishments, providing specific examples of your contributions to previous projects.

- Be prepared to discuss your proficiency in operating edge molding machinery, including your knowledge of cutting tools and techniques.

3. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that showcase your strengths and alignment with the job.

- Describe your experience in edge molding and the types of machinery you have worked with.

- Explain how you ensure the precision and quality of your work in edge molding.

4. Seek Feedback and Refine Your Approach

Conduct mock interviews with friends, family members, or a career counselor to gain feedback on your performance. This helps you identify areas for improvement.

- Ask for specific suggestions on how to enhance your answers and make a stronger impression.

- Practice active listening and incorporate feedback into your interview preparation.

5. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving at the interview on time. This demonstrates your respect for the interviewer and the opportunity.

- Choose attire that is clean, pressed, and appropriate for a manufacturing environment.

- Plan your travel route in advance to avoid any delays or stress.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Edge Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!