Feeling lost in a sea of interview questions? Landed that dream interview for Edger Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Edger Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

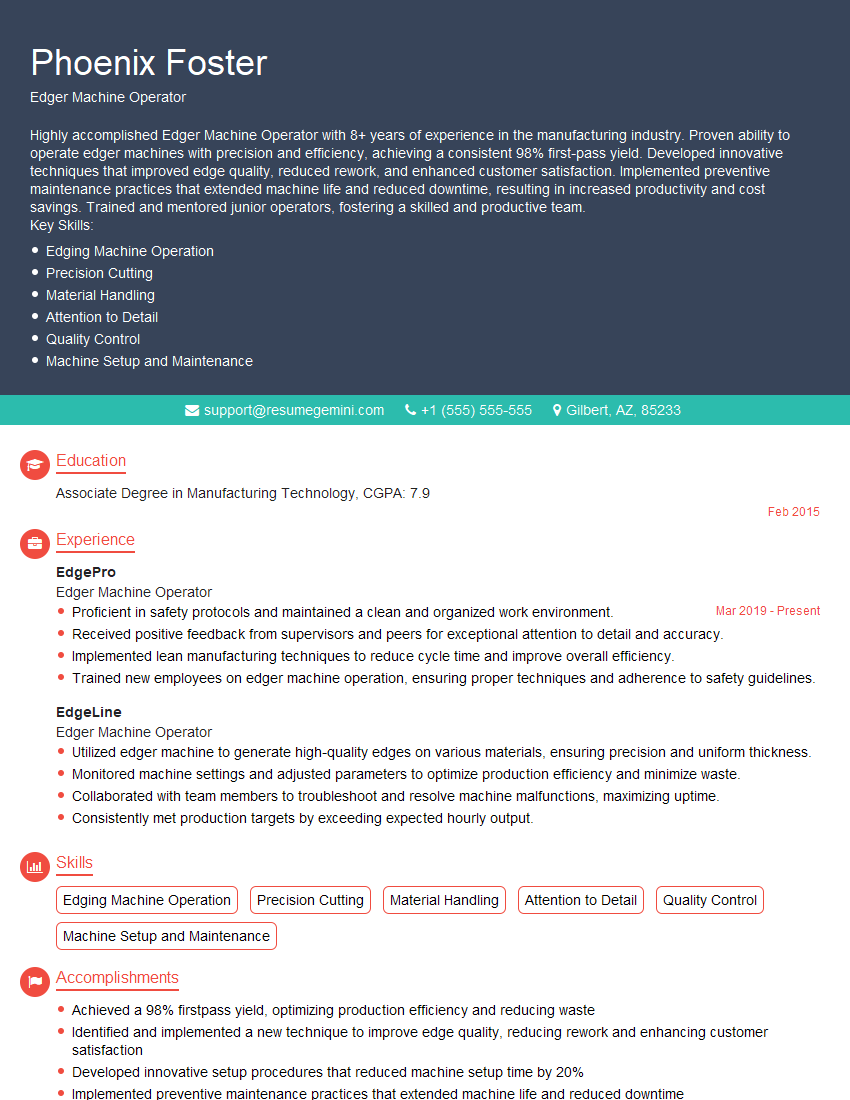

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Edger Machine Operator

1. How do you ensure that the edges of the materials are cut accurately and smoothly?

- Inspect and ensure that the edger machine is properly calibrated and adjusted.

- Utilize sharp and high-quality blades that are suitable for the specific material being edged.

- Maintain a steady and consistent feed rate during the edging process to prevent uneven cuts.

- Pay attention to the grain direction of the material to optimize the cutting process and achieve a smooth finish.

- Regularly clean and maintain the edger machine to prevent any debris or build-up from affecting the cutting accuracy.

2. What techniques do you use to minimize waste and maximize material utilization?

Optimizing Cutting Patterns

- Plan and create efficient cutting patterns to minimize material waste and maximize utilization.

- Nest and arrange the pieces to be cut in a way that minimizes the amount of scrap material generated.

Utilizing Offcuts

- Identify opportunities to reuse offcuts or smaller pieces of material for other purposes.

- Store and organize offcuts for potential future use in smaller projects or repairs.

3. How do you troubleshoot and resolve common issues that may arise while operating the edger machine?

- Identify and address any mechanical issues with the machine, such as loose belts, worn bearings, or malfunctioning sensors.

- Troubleshoot electrical problems by checking connections, fuses, and wiring for any faults or damage.

- Inspect and adjust the cutting blades to ensure they are sharp and properly aligned for optimal performance.

- Monitor the material feed rate and make adjustments as needed to prevent jamming or uneven cutting.

- Regularly clean and maintain the machine to prevent debris or build-up from causing operational issues.

4. What safety precautions do you take when operating the edger machine?

- Always wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves.

- Ensure that the machine is properly grounded and all electrical connections are secure.

- Keep the work area clean and free from tripping hazards or debris.

- Never operate the machine under the influence of alcohol or drugs.

- Receive proper training and authorization before operating the edger machine.

5. How do you maintain and calibrate the edger machine to ensure optimal performance?

- Regularly clean and lubricate the machine according to the manufacturer’s instructions.

- Inspect and replace worn or damaged parts, such as belts, bearings, and blades.

- Calibrate the machine to ensure accurate cutting dimensions and angles.

- Follow the manufacturer’s recommended maintenance schedule to prolong the machine’s lifespan.

- Keep a maintenance log to record all inspections, repairs, and calibrations performed on the machine.

6. How do you determine the correct feed rate and blade speed for different materials?

- Refer to the manufacturer’s specifications for recommended feed rates and blade speeds for different materials.

- Experiment with different settings to determine the optimal combination for the specific material being edged.

- Consider factors such as the hardness, thickness, and grain direction of the material.

- Make adjustments to the feed rate and blade speed as needed to achieve the desired cut quality and efficiency.

7. How do you ensure that the finished edges meet the required specifications and quality standards?

- Carefully inspect the finished edges to ensure they meet the specified dimensions and tolerances.

- Use measuring tools and gauges to verify the accuracy of the cuts.

- Check for any defects or imperfections, such as chips, cracks, or uneven surfaces.

- Make adjustments to the machine settings or cutting process as needed to correct any deviations from the required specifications.

8. How do you handle and store materials safely to prevent damage or accidents?

- Properly store materials in designated areas to prevent damage or accidents.

- Use appropriate handling equipment, such as forklifts or cranes, to move heavy or bulky materials.

- Stack materials securely to prevent them from falling or collapsing.

- Protect materials from moisture, heat, and other environmental factors that could cause damage.

- Label and identify materials clearly to prevent confusion or mix-ups.

9. How do you work effectively as part of a team in a production environment?

- Communicate effectively with team members to ensure smooth operations and timely completion of tasks.

- Assist colleagues and provide support when needed, fostering a positive and collaborative work environment.

- Follow established procedures and safety protocols to maintain a safe and efficient work area.

- Offer suggestions for process improvements and share knowledge and expertise with the team.

- Adapt to changing priorities and workload demands, demonstrating flexibility and a commitment to team success.

10. What motivates you to excel as an Edger Machine Operator?

- The satisfaction of producing high-quality finished products that meet or exceed specifications.

- The opportunity to contribute to the success of the team and the company’s overall goals.

- The challenge of working with different materials and finding innovative solutions to achieve the desired results.

- The continuous learning and development opportunities that come with operating and maintaining complex machinery.

- The pride in craftsmanship and the desire to create products that are both functional and aesthetically pleasing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Edger Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Edger Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Edger Machine Operators are responsible for operating, monitoring, and maintaining edger machines in lumber mills or production facilities. They play a crucial role in ensuring the production of high-quality lumber by accurately trimming and edging boards.

1. Machine Operation

Edger Machine Operators are primarily responsible for operating edger machines. They load lumber boards onto the machine’s conveyor belt and adjust machine settings to ensure precise trimming and edging. They monitor the machine during operation and adjust settings to optimize efficiency and reduce defects.

2. Quality Control

Edger Machine Operators are responsible for maintaining the quality of the lumber produced. They visually inspect boards for defects and remove any damaged or substandard pieces. They also make adjustments to the machine to achieve the desired lumber dimensions and quality.

3. Machine Maintenance

Edger Machine Operators perform routine maintenance and repairs on edger machines to ensure optimal performance. They lubricate machine parts, adjust components, and perform necessary repairs to keep the machine running smoothly.

4. Safety Compliance

Edger Machine Operators prioritize safety in the workplace. They follow safety protocols, wear appropriate protective gear, and adhere to regulations to prevent accidents and injuries on the job.

Interview Tips

Preparing for an Edger Machine Operator interview requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company you’re applying for and the specific job responsibilities. This will demonstrate your interest and preparedness during the interview.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating edger machines, including the types of machines you’ve worked with and the quality standards you’ve met. Mention any relevant skills, such as troubleshooting, machine maintenance, and attention to detail.

3. Quantify Your Accomplishments

When describing your experience, use specific examples and quantify your accomplishments whenever possible. For instance, instead of saying “I maintained edger machines,” say “I reduced machine downtime by 15% through proactive maintenance.”

4. Prepare for Technical Questions

Be prepared to answer questions about edger machine operation, maintenance, and troubleshooting. Practice common questions, such as “How do you adjust the blade angle on an edger machine?” or “What are the common causes of edger machine defects?”

5. Be Enthusiastic and Professional

Show your enthusiasm for the position and the company by asking thoughtful questions and expressing your interest in contributing to the team. Maintain a professional demeanor throughout the interview and demonstrate your communication skills.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Edger Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.