Feeling lost in a sea of interview questions? Landed that dream interview for Edging Machine Feeder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Edging Machine Feeder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

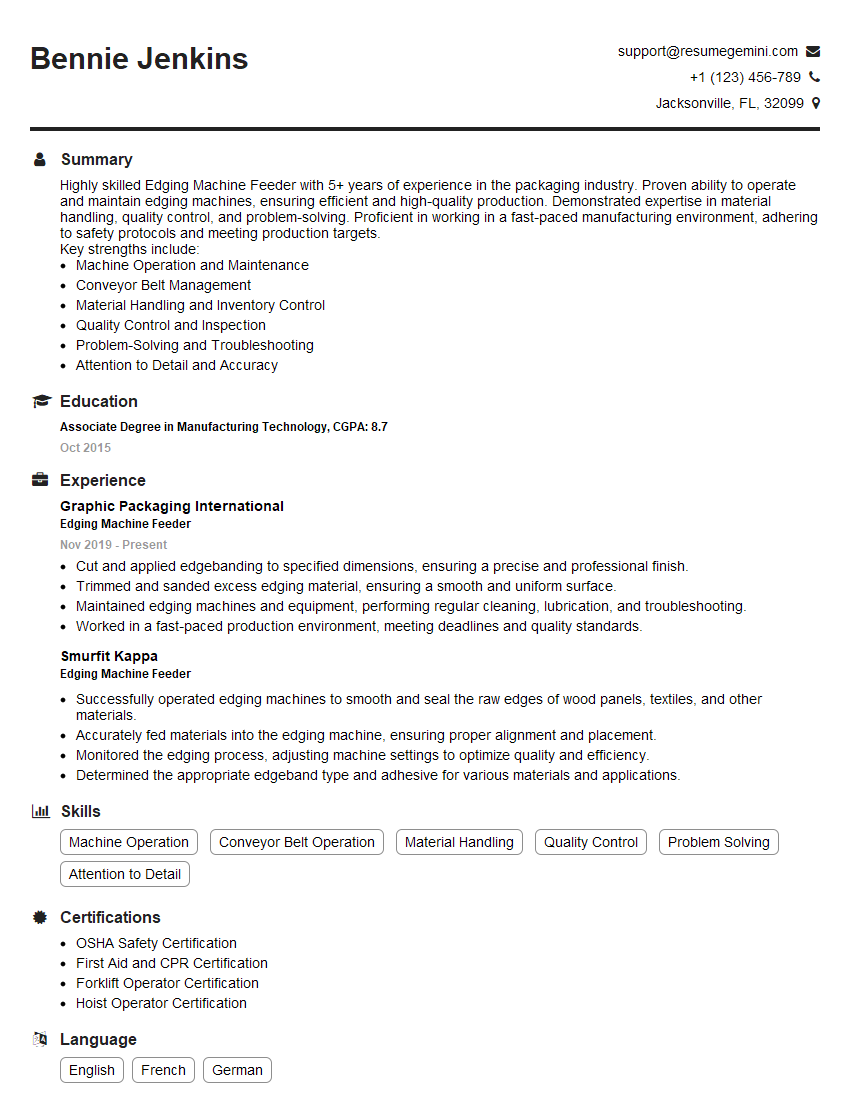

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Edging Machine Feeder

1. What are the key responsibilities of an Edging Machine Feeder?

As an Edging Machine Feeder, my primary responsibilities would be:

- Loading and feeding fabrics onto the edging machine

- Monitoring the machine’s operation and adjusting the feed rate as needed

- Inspecting the finished edges for quality and consistency

- Maintaining the machine and work area in a clean and safe condition

- Following safety protocols and reporting any potential hazards

2. What are the different types of edging machines and their uses?

Flat Edging Machine

- Used to create a flat, folded edge on fabrics

- Ideal for garments, curtains, and tablecloths

Double Fold Edging Machine

- Creates a double-folded edge, providing a stronger and more durable finish

- Used for industrial applications and heavy-duty fabrics

3. What are the critical quality parameters to consider when edging fabrics?

The critical quality parameters for edging fabrics include:

- Edge width and consistency

- Uniformity and straightness of the fold

- Absence of puckering, wrinkles, or distortion

- Proper tension and tightness of the fold

- Durability and resistance to wear and tear

4. What are the common troubleshooting techniques for edging machines?

Common troubleshooting techniques for edging machines include:

- Checking for thread tension issues

- Adjusting the feed rate or machine speed

- Cleaning and lubricating the machine

- Replacing worn or damaged needles

- Inspecting the fabric for defects or inconsistencies

5. How do you ensure the safety and efficiency of the edging process?

To ensure safety and efficiency in the edging process, I would:

- Follow all safety guidelines and wear appropriate protective gear

- Inspect the machine regularly and report any potential hazards

- Maintain a clean and organized work area

- Use proper lifting techniques and avoid overexertion

- Communicate effectively with colleagues and supervisors

6. What are the different types of fabrics that can be edged using an edging machine?

An edging machine can handle a wide range of fabrics, including:

- Cotton and cotton blends

- Synthetics such as polyester and nylon

- Silk and satin

- Denim and canvas

- Lace and embroidery

7. What are the key maintenance tasks required for an edging machine?

Regular maintenance tasks for an edging machine include:

- Cleaning and lubricating the machine regularly

- Checking and adjusting thread tension

- Inspecting and replacing needles as needed

- Tightening loose bolts or screws

- Monitoring the machine’s performance and reporting any issues

8. What are the potential challenges in the role of an Edging Machine Feeder?

Some potential challenges in this role could be:

- Working with a variety of fabrics and adjusting the machine accordingly

- Meeting production targets while maintaining quality standards

- Working in a fast-paced and demanding environment

- Handling potential machine malfunctions or breakdowns

- Ensuring the proper training and supervision of new employees

9. How do you stay up-to-date with the latest advancements in edging machine technology?

To stay informed, I would:

- Attend industry workshops and conferences

- Read trade magazines and industry publications

- Participate in online forums and discussions

- Research and explore new technologies through vendor websites

- Seek guidance and advice from experienced professionals

10. What sets you apart from other candidates for this role?

My key strengths include:

- Extensive experience in fabric edging operations

- Proven ability to produce high-quality edged products consistently

- Strong attention to detail and commitment to quality control

- Excellent mechanical aptitude and ability to troubleshoot machine issues

- Strong work ethic, adaptability, and willingness to learn new skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Edging Machine Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Edging Machine Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Edging Machine Feeder is an integral part of a manufacturing operation, responsible for ensuring a smooth and efficient production process. The key responsibilities of an Edging Machine Feeder can be categorized as follows:

1. Material Handling

An Edging Machine Feeder is responsible for manually feeding materials, such as metal sheets, plastic sheets, or other materials, into the edging machine. This involves accurately positioning and guiding the material through the machine to ensure a precise and clean cut.

- Loading and unloading materials from the edging machine

- Adjusting material placement for optimal cutting

2. Machine Operation

The feeder operates the edging machine, ensuring it is functioning properly and making necessary adjustments as required. This may involve setting up the machine, adjusting cutting parameters, and monitoring the cutting process.

- Controlling the speed and feed rate of the edging machine

- Monitoring cutting quality and making adjustments

3. Quality Control

The feeder ensures that the finished products meet the required quality standards by visually inspecting the cut edges and identifying any defects or deviations from specifications.

- Inspecting cut edges for burrs, tears, or other defects

- Reporting any quality issues to the supervisor

4. Maintenance and Safety

To maintain a safe and efficient work environment, the feeder is responsible for performing routine maintenance on the edging machine, including cleaning, lubrication, and minor repairs. They also adhere to safety regulations and follow established work procedures.

- Cleaning and lubricating the edging machine

- Performing minor repairs and adjustments

Interview Tips

Preparing thoroughly for an Edging Machine Feeder interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company you’re applying to, including their industry, products, and company culture. Researching the specific position and its requirements will demonstrate your interest and understanding of the role.

- Visit the company’s website and social media pages

- Read industry-related articles and news to stay updated

2. Practice Common Interview Questions

Prepare for common interview questions related to manufacturing, machine operation, and quality control. Practice answering these questions clearly and concisely, highlighting your relevant skills and experience.

- “Tell me about your experience operating edging machines.”

- “How do you ensure the quality of the finished products?”

3. Highlight Your Skills and Experience

Emphasize the skills and experience that are most relevant to the Edging Machine Feeder position. Quantify your accomplishments whenever possible using specific examples and metrics.

- Discuss your ability to handle and feed materials accurately

- Provide examples of your attention to detail and commitment to quality

4. Be Enthusiastic and Engaged

Throughout the interview, show enthusiasm for the position and the industry. Ask thoughtful questions to demonstrate your interest and engagement. Maintain a positive and professional demeanor throughout the interview process.

- Inquire about the company’s growth plans and future projects

- Express your passion for manufacturing and working with machinery

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Edging Machine Feeder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.