Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Efficiency Analyst position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

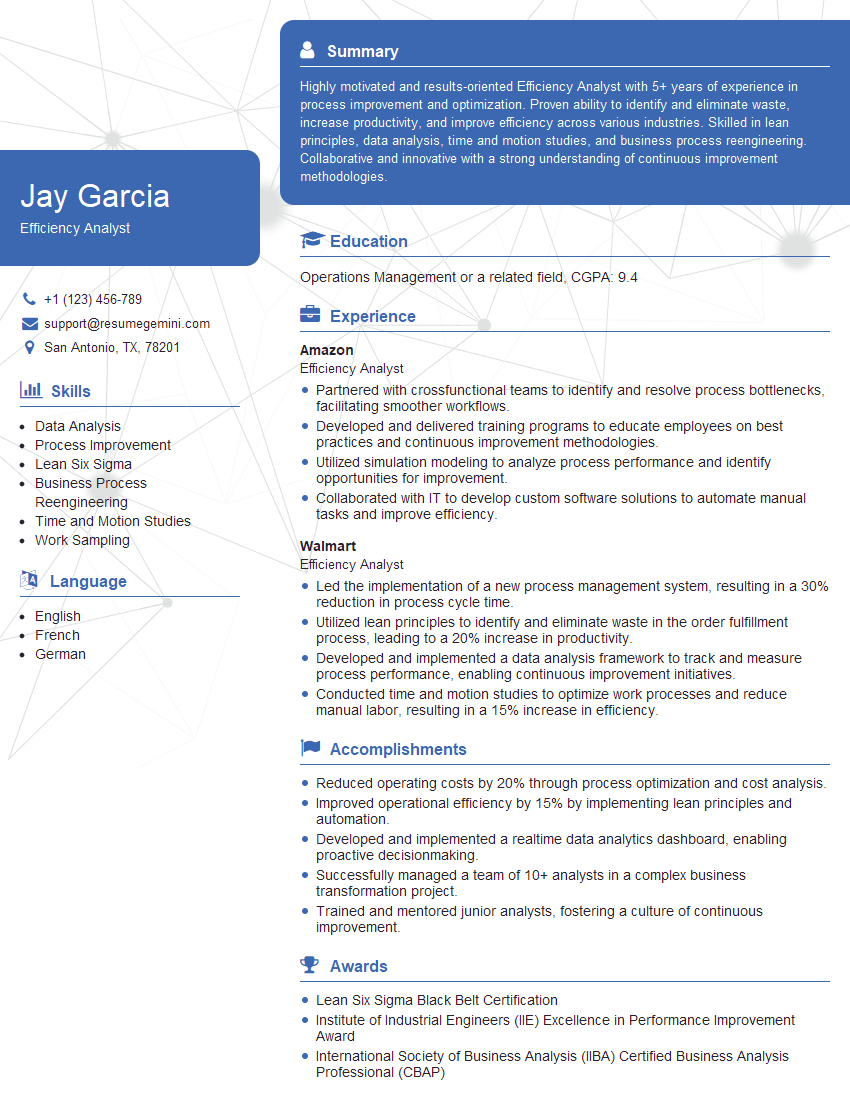

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Efficiency Analyst

1. What are the key responsibilities of an Efficiency Analyst?

As an Efficiency Analyst, I am responsible for analyzing and evaluating business processes to identify areas for improvement. I gather data, conduct interviews, and observe workflows to identify and recommend changes that can enhance efficiency, reduce costs, and improve productivity.

2. Describe the different techniques you use for evaluating process efficiency.

Time and motion studies

- Recording and analyzing the time spent on each task within a process to identify bottlenecks.

- Observing and documenting the physical movements of workers to optimize workflows.

Process mapping

- Creating visual representations of processes to identify redundancies, inefficiencies, and areas for improvement.

- Using flowcharts, swim lanes, and other diagrams to analyze process flow.

Data analysis

- Collecting and analyzing data on process performance metrics, such as cycle times, error rates, and resource utilization.

- Using statistical techniques to identify trends, patterns, and areas for improvement.

3. How do you prioritize process improvement initiatives based on their potential impact?

I prioritize process improvement initiatives based on the following criteria:

- Impact on business goals: I assess the potential impact of the improvement on key metrics such as revenue, cost, customer satisfaction, and employee productivity.

- Feasibility: I evaluate the resources, time, and effort required to implement the improvement and assess its technical and organizational feasibility.

- Urgency: I consider the time-sensitive nature of the improvement and determine if it needs to be addressed immediately or can be scheduled for later implementation.

- Alignment with strategic objectives: I ensure that the improvement is aligned with the overall strategic goals and priorities of the organization.

4. What are some common challenges you face in implementing process improvements?

Some common challenges in implementing process improvements include:

- Resistance to change: Employees may be resistant to changes in their workflows or processes, especially if they have been doing them the same way for a long time.

- Lack of resources: Implementing process improvements may require additional resources, such as time, money, or staff, which may not always be available.

- Technology limitations: Some process improvements may require changes to existing technologies, which can be time-consuming and expensive to implement.

- Lack of stakeholder support: If stakeholders, such as managers or executives, are not fully supportive of the process improvement initiative, it may be difficult to implement and sustain the changes.

5. How do you measure the success of a process improvement initiative?

I measure the success of a process improvement initiative by evaluating its impact on key performance indicators (KPIs).

- Quantifiable metrics: I track quantifiable metrics, such as cycle time, error rates, throughput, and costs, to measure the direct impact of the improvement on process efficiency.

- Customer feedback: I gather feedback from customers to assess their satisfaction with the improved process and identify areas for further improvement.

- Employee feedback: I collect feedback from employees involved in the process to evaluate their satisfaction with the improvement and identify any areas for adjustment.

- Return on investment (ROI): I calculate the ROI of the improvement to determine its financial impact on the organization.

6. What are some emerging trends in process improvement?

Some emerging trends in process improvement include:

- Automation: Leveraging technology to automate repetitive and labor-intensive tasks, reducing manual effort and improving efficiency.

- Process mining: Using data analysis techniques to extract insights from process logs and identify areas for improvement.

- Agile methodologies: Adopting agile principles, such as iterative development and continuous improvement, to facilitate rapid and flexible process changes.

- Artificial intelligence (AI): Employing AI algorithms to analyze data, identify patterns, and provide recommendations for process optimization.

- Customer-centricity: Designing and improving processes with a focus on enhancing customer experience and satisfaction.

7. What is your experience with Lean Six Sigma?

I have extensive experience with Lean Six Sigma, a process improvement methodology that focuses on eliminating waste and improving efficiency. I am certified as a Lean Six Sigma Green Belt and have applied the principles of Lean Six Sigma in various process improvement projects.

- Define: Clearly defining the problem statement and project scope.

- Measure: Collecting and analyzing data to establish a baseline for improvement.

- Analyze: Identifying the root causes of the problem using statistical tools and techniques.

- Improve: Developing and implementing solutions to eliminate waste and improve efficiency.

- Control: Establishing mechanisms to monitor and sustain the improvements over time.

8. Describe a successful process improvement project you have led.

In my previous role, I led a successful process improvement project to streamline the order fulfillment process for an e-commerce company. By implementing Lean Six Sigma principles, I identified bottlenecks in the process and developed solutions to reduce cycle time and improve accuracy.

- Reduced cycle time by 25%: Automated manual tasks and optimized the workflow to reduce the time it took to process and fulfill orders.

- Improved accuracy by 15%: Implemented quality control measures and standardized processes to reduce errors in order fulfillment.

- Increased customer satisfaction by 10%: Reduced delivery times and improved order accuracy, leading to increased customer satisfaction.

9. How do you stay up-to-date with the latest process improvement best practices?

I stay up-to-date with the latest process improvement best practices through various channels:

- Attending industry conferences and workshops: I regularly attend industry events to learn about emerging trends, best practices, and new technologies in process improvement.

- Reading professional journals and articles: I subscribe to industry publications and online resources to stay informed about the latest research and developments in process improvement.

- Networking with other professionals: I connect with other efficiency analysts and process improvement experts through professional organizations and online forums to share knowledge and learn from their experiences.

- Continuing education: I pursue professional development opportunities, such as online courses and certification programs, to enhance my knowledge and skills in process improvement.

10. What is your approach to continuous process improvement (CPI)?

I believe that continuous process improvement is crucial for sustained organizational efficiency and success. My approach to CPI involves the following steps:

- Establish a baseline: Measuring and documenting current process performance to establish a baseline against which improvements can be tracked.

- Identify areas for improvement: Regularly reviewing process performance and identifying areas where efficiency, quality, or customer satisfaction can be enhanced.

- Develop and implement improvements: Collaborating with stakeholders to develop and implement process improvements that address identified areas for improvement.

- Monitor and evaluate results: Tracking the impact of process improvements and evaluating their effectiveness in achieving desired outcomes.

- Sustain improvements: Establishing mechanisms to ensure that process improvements are sustained over time and become part of the organization’s culture.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Efficiency Analyst.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Efficiency Analyst‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Efficiency Analysts are responsible for enhancing operational efficiency within an organization. They play a critical role in identifying and addressing inefficiencies, implementing process improvements, and developing strategies to optimize productivity.

1. Identify and Analyze Business Processes

Efficiency Analysts examine existing business processes to pinpoint areas for improvement. They leverage data analysis techniques and statistical tools to assess process performance, identify bottlenecks, and uncover potential roadblocks.

- Conduct process mapping and workflow analysis

- Evaluate process metrics, such as cycle time, throughput, and cost

2. Design and Implement Process Improvements

Based on their analysis, Efficiency Analysts devise and implement process improvements to enhance efficiency. They work closely with stakeholders to gather input and develop solutions that align with business objectives.

- Develop and test process automation solutions

- Implement lean principles and Six Sigma methodologies

3. Monitor and Evaluate Process Effectiveness

Efficiency Analysts continuously monitor and evaluate the effectiveness of implemented process improvements. They collect data, track metrics, and conduct root cause analysis to identify any issues or areas for further improvement.

- Track process performance and identify areas for optimization

- Make recommendations for additional process enhancements

4. Collaborate with Stakeholders

Efficiency Analysts collaborate closely with various stakeholders, including business leaders, process owners, and employees. They communicate findings, provide recommendations, and foster a culture of continuous improvement.

- Build strong relationships with stakeholders

- Communicate complex technical information clearly

Interview Tips

To ace an interview for an Efficiency Analyst position, candidates should:

1. Highlight Relevant Experience and Skills

Emphasize your experience in process analysis, process improvement, and data analysis. Showcase your proficiency in relevant tools and methodologies, such as Lean, Six Sigma, and process mapping.

- Share specific examples of process improvements you implemented and the positive outcomes they led to.

- Demonstrate your ability to analyze data, identify trends, and develop data-driven solutions.

2. Prepare Case Studies

Be prepared to present case studies that showcase your problem-solving and analytical skills. Choose examples that highlight your ability to identify inefficiencies, design improvements, and measure their effectiveness.

- Provide a brief overview of the problem you addressed, the approach you took, and the results you achieved.

- Quantify your results whenever possible to demonstrate the tangible impact of your work.

3. Emphasize Collaboration and Communication

Stress your ability to build relationships with stakeholders, communicate effectively, and foster a culture of continuous improvement. Highlight experiences where you successfully collaborated with others to improve processes.

- Share examples of how you effectively communicated complex technical information to non-technical stakeholders.

- Explain how you built trust and obtained buy-in for your improvement initiatives.

4. Practice Behavioral Interview Questions

Be prepared to answer behavioral interview questions that assess your problem-solving, analytical, and interpersonal skills. Use the STAR method to structure your answers and provide specific examples:

- Describe a time you faced a complex problem and how you approached it.

- Tell me about a time you had to influence others to accept a new process or idea.

Next Step:

Now that you’re armed with the knowledge of Efficiency Analyst interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Efficiency Analyst positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini