Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electric Clock Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

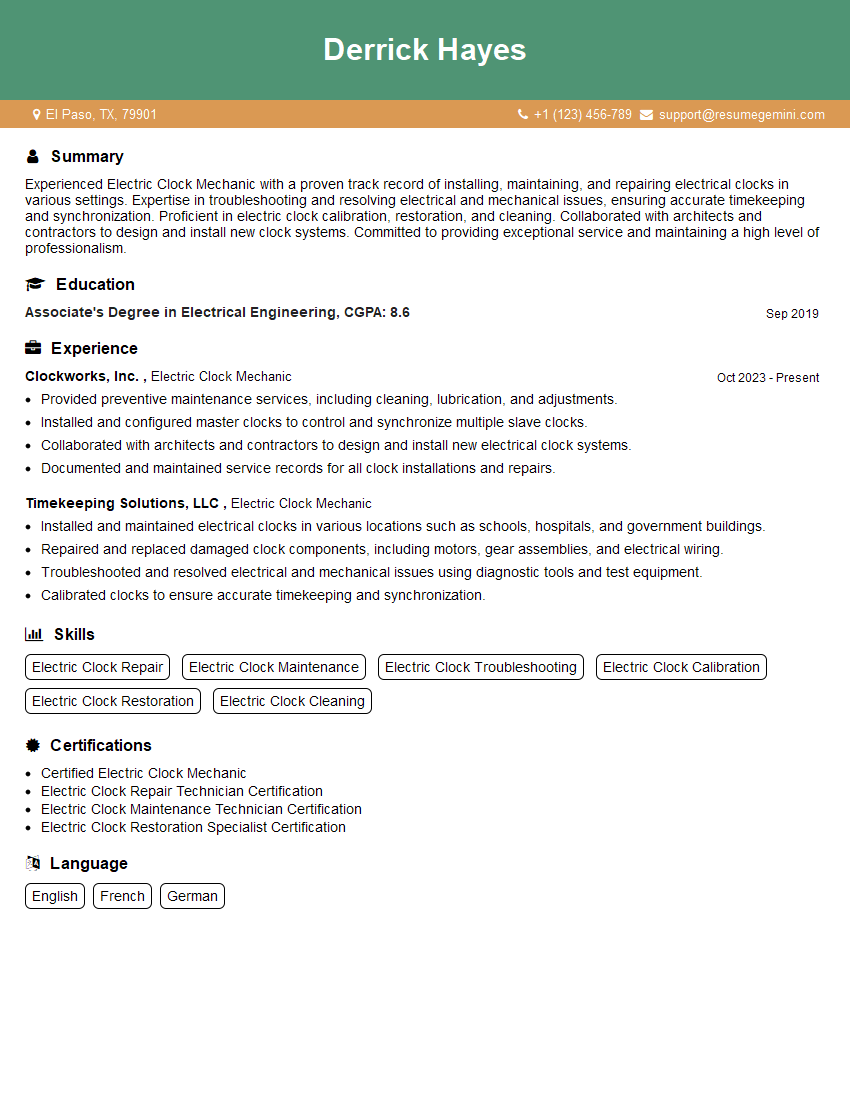

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Clock Mechanic

1. What are the common types of electric clocks and how do they differ in terms of their mechanisms?

- AC synchronous clocks: These clocks use an AC motor to drive the clock mechanism. The motor is synchronized to the AC power line frequency, which ensures that the clock keeps accurate time.

- DC synchronous clocks: These clocks use a DC motor to drive the clock mechanism. The motor is synchronized to a quartz crystal oscillator, which ensures that the clock keeps accurate time.

- Battery-powered clocks: These clocks use a battery to power the clock mechanism. The battery provides a constant voltage to the motor, which ensures that the clock keeps accurate time.

2. Explain the working principle of a stepper motor used in electric clocks.

Principle of operation:

- A stepper motor is a type of electric motor that moves in discrete steps.

- It consists of a rotor with a permanent magnet and a stator with a set of electromagnets.

- When an electromagnet is energized, it attracts the rotor magnet, causing the rotor to move one step.

- By energizing the electromagnets in a specific sequence, the rotor can be made to rotate in either direction.

Advantages in electric clocks:

- Stepper motors are used in electric clocks because they provide precise control over the movement of the clock hands.

- They are also very reliable and can operate for long periods of time without maintenance.

3. What are the different types of faults that can occur in electric clocks and how do you diagnose and repair them?

- Power supply problems: These can be caused by a faulty power cord, a blown fuse, or a problem with the electrical outlet.

- Motor problems: These can be caused by a worn-out motor, a damaged gear, or a problem with the electrical connections.

- Circuit board problems: These can be caused by a faulty component, a short circuit, or a broken trace.

To diagnose and repair these faults, you will need to use a multimeter to test the electrical components and circuits. You may also need to replace faulty components or repair damaged parts.

4. How do you calibrate an electric clock to ensure accurate timekeeping?

- First, you need to connect the clock to a power source and set the time.

- Next, you need to monitor the clock’s accuracy over a period of time.

- If the clock is losing or gaining time, you need to adjust the clock’s speed.

- To adjust the clock’s speed, you need to use a small screwdriver to turn the adjustment screw on the back of the clock.

You should continue to monitor the clock’s accuracy until it is keeping accurate time.

5. What are the safety precautions that must be taken when working on electric clocks?

- Always unplug the clock from the power source before working on it.

- Be careful not to touch any exposed wires or components.

- Use proper tools and equipment for the job.

- If you are not comfortable working on electrical devices, it is best to consult with a qualified electrician.

6. What are the different types of batteries used in electric clocks and how do you replace them?

- Alkaline batteries: These are the most common type of battery used in electric clocks. They provide a long lifespan and are relatively inexpensive.

- Lithium batteries: These batteries provide a longer lifespan than alkaline batteries, but they are also more expensive.

- Mercury batteries: These batteries were once commonly used in electric clocks, but they are now banned in many countries due to their environmental impact.

To replace the batteries in an electric clock, you will need to open the back of the clock and locate the battery compartment. Once you have found the battery compartment, you will need to remove the old batteries and insert the new batteries.

7. How do you troubleshoot an electric clock that is not working?

- First, check to make sure that the clock is plugged into a power source and that the power cord is not damaged.

- Next, check the batteries to make sure that they are fresh.

- If the clock is still not working, you may need to open the back of the clock and inspect the electrical components.

- Look for any loose connections, damaged wires, or burnt-out components.

- If you find any problems, you will need to repair or replace the damaged components.

8. What are the different types of materials used in the construction of electric clocks?

- Metals: Metals are used for the clock’s frame, gears, and other mechanical components.

- Plastics: Plastics are used for the clock’s housing, dials, and other non-mechanical components.

- Glass: Glass is used for the clock’s face and crystal.

9. What are the different types of finishes used on electric clocks?

- Painted finishes: Painted finishes are applied to the clock’s metal and plastic components.

- Plated finishes: Plated finishes are applied to the clock’s metal components.

- Anodized finishes: Anodized finishes are applied to the clock’s aluminum components.

10. How do you maintain an electric clock to ensure its longevity?

- Keep the clock clean and free of dust.

- Replace the batteries regularly.

- Avoid exposing the clock to extreme temperatures or humidity.

- Have the clock serviced by a qualified electrician every few years.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Clock Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Clock Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Clock Mechanics are responsible for maintaining, repairing, and overhauling electric clocks and timekeeping systems.

1. Troubleshooting

Electric Clock Mechanics are responsible for troubleshooting and repairing electric clocks and timekeeping systems. They use their knowledge of electrical circuits and mechanical components to identify and fix problems.

- Use electrical testing equipment to identify faults in electrical circuits.

- Replace faulty components, such as capacitors, resistors, and transistors.

2. Calibration

Electric Clock Mechanics are responsible for calibrating electric clocks and timekeeping systems. They use specialized equipment to ensure that clocks are accurate and keep time properly.

- Use specialized equipment to calibrate clocks to the correct time.

- Adjust the clock’s speed to ensure that it keeps accurate time.

3. Maintenance

Electric Clock Mechanics are responsible for maintaining electric clocks and timekeeping systems. They perform regular maintenance tasks, such as cleaning and lubricating components, to keep the clocks running smoothly.

- Clean and lubricate clock components to prevent wear and tear.

- Inspect clocks for any signs of damage or wear.

4. Installation

Electric Clock Mechanics are responsible for installing electric clocks and timekeeping systems. They must follow the manufacturer’s instructions to ensure that the clocks are installed correctly and safely.

- Install clocks and timekeeping systems according to the manufacturer’s instructions.

- Connect the clocks to the electrical supply.

Interview Tips

An interview for an Electric Clock Mechanic position can be a challenging but rewarding experience. To prepare for an interview, follow these tips:

1. Research the company.

Before your interview, take some time to research the company you’re applying to. Learn about their history, their products or services, and their company culture. This will help you to answer questions intelligently and show the interviewer that you’re interested in the position.

- Visit the company’s website.

- Read articles and news stories about the company.

- Talk to people who work at the company.

2. Practice answering common interview questions.

There are several common interview questions that you may be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Practice answering these questions aloud, so you can become comfortable talking about yourself.

- Use the STAR method to answer interview questions.

- Be specific and provide examples.

- Practice with a friend or family member.

3. Be prepared to talk about your experience.

The interviewer will likely ask you about your experience as an Electric Clock Mechanic. Be prepared to discuss your skills and experience in detail. If you have any specific projects or accomplishments that you’re proud of, be sure to highlight them.

- Bring a portfolio of your work to the interview.

- Be prepared to answer questions about your experience with specific types of clocks.

- Have a list of your references ready to provide to the interviewer.

4. Dress appropriately.

First impressions matter, so make sure to dress appropriately for your interview. Avoid wearing jeans or t-shirts, and instead opt for dress pants or a skirt and a button-down shirt. You should also make sure your clothes are clean and pressed.

- Dress in a way that is appropriate for the company culture.

- Make sure your clothes are clean and pressed.

- Wear comfortable shoes.

5. Be confident and positive.

Confidence is key in an interview. Believe in yourself and your ability to do the job. Make eye contact with the interviewer, speak clearly and confidently, and be enthusiastic about the position.

- Practice positive self-talk.

- Visualize yourself succeeding in the interview.

- Focus on your strengths and accomplishments.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Clock Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!