Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Electric Deicer Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Electric Deicer Assembler so you can tailor your answers to impress potential employers.

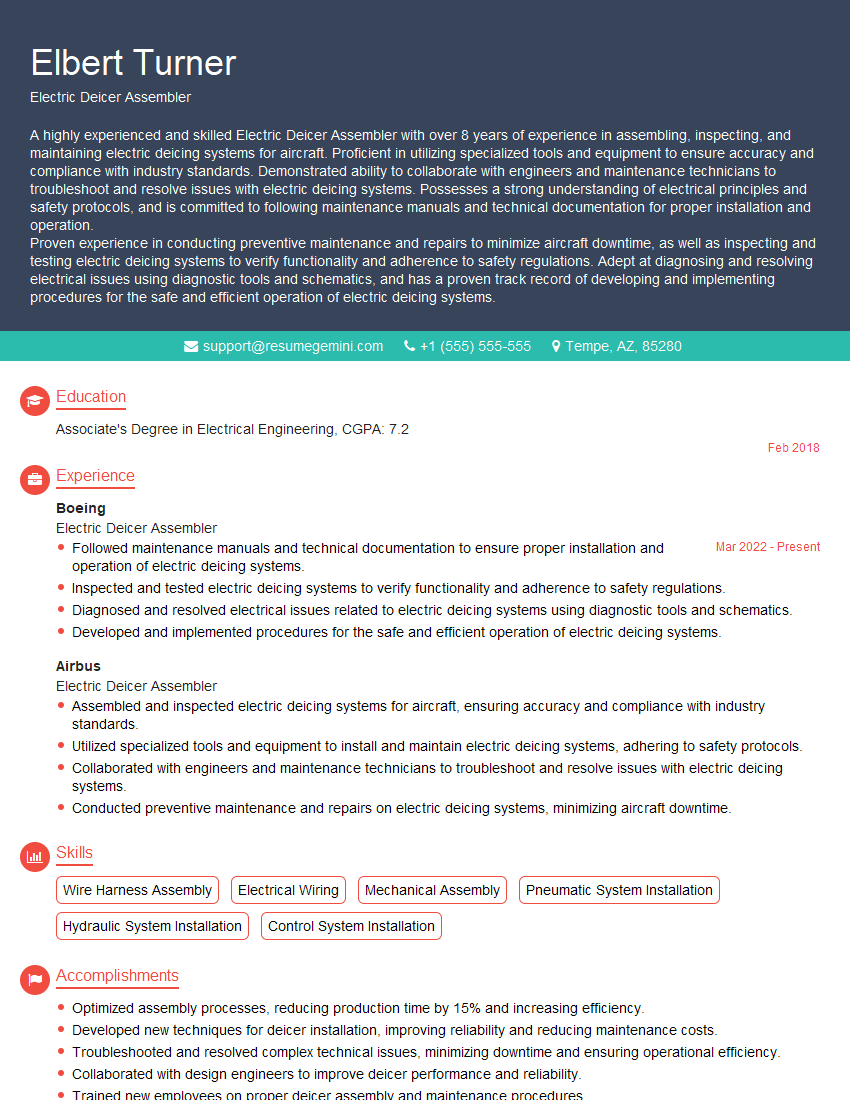

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Deicer Assembler

1. What are the different types of electric deicers and how do they work?

Electric deicers use electrical resistance to heat up and melt ice and snow. There are two main types of electric deicers: carbon fiber and metal heating elements.

- Carbon fiber deicers are made of a thin, flexible material that is coated with a conductive material. When electricity is passed through the carbon fiber, it heats up and melts ice and snow.

- Metal heating elements are made of a metal alloy that is heated by electricity. Metal heating elements are more durable than carbon fiber deicers, but they are also more expensive.

2. What are the different components of an electric deicer?

- Heating element: The heating element is the part of the deicer that generates heat. It is typically made of carbon fiber or a metal alloy.

- Thermal insulation: The thermal insulation helps to keep the heat in the deicer and prevent it from escaping. It is typically made of a material such as fiberglass or foam.

- Electrical connections: The electrical connections allow the deicer to be connected to a power source. They are typically made of copper or aluminum.

- Mounting hardware: The mounting hardware allows the deicer to be attached to a surface. It is typically made of stainless steel or aluminum.

3. How do you assemble an electric deicer?

To assemble an electric deicer, you will need to:

- Cut the heating element to the desired length.

- Attach the thermal insulation to the heating element.

- Connect the electrical connections to the heating element.

- Mount the deicer to the surface using the mounting hardware.

4. What are the safety precautions that need to be taken when working with electric deicers?

- Always wear gloves and safety glasses when working with electric deicers.

- Do not touch the heating element when it is turned on.

- Do not operate the deicer in a wet environment.

- Do not use the deicer on a surface that is not rated for its heat output.

- Unplug the deicer when it is not in use.

5. What are the troubleshooting tips for electric deicers?

- If the deicer is not heating up, check the electrical connections.

- If the deicer is overheating, check the thermal insulation.

- If the deicer is not melting ice and snow, check the heating element.

- If the deicer is making a noise, check the mounting hardware.

6. What are the maintenance tips for electric deicers?

- Inspect the deicer regularly for any damage.

- Clean the deicer with a mild detergent and water.

- Replace the heating element every 5-10 years.

- Replace the thermal insulation every 10-15 years.

7. What are the benefits of using electric deicers?

- Electric deicers are safe and easy to use.

- Electric deicers are effective at melting ice and snow.

- Electric deicers are relatively inexpensive to operate.

- Electric deicers are durable and can last for many years.

8. What are the drawbacks of using electric deicers?

- Electric deicers can be expensive to purchase.

- Electric deicers require electricity to operate.

- Electric deicers can be a tripping hazard.

- Electric deicers can be a fire hazard if they are not used properly.

9. What is the difference between an electric deicer and a chemical deicer?

- Electric deicers use electricity to heat up and melt ice and snow.

- Chemical deicers use chemicals to lower the freezing point of ice and snow.

10. What is the best way to choose an electric deicer?

- Consider the size of the area you need to deice.

- Consider the type of surface you need to deice.

- Consider the climate in your area.

- Consider your budget.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Deicer Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Deicer Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Assembly and Inspection

Assembles electric deicers according to engineering specifications and established procedures.

- Follows work orders, blueprints, and schematics to ensure accurate assembly.

- Selects and installs components, such as heating elements, sensors, and wiring.

- Conducts quality inspections to verify that assembled deicers meet all specifications.

2. Testing and Troubleshooting

Performs electrical and functional tests on assembled deicers.

- Uses specialized equipment to test electrical circuits, voltage, and amperage.

- Troubleshoots any malfunctions or defects and makes necessary repairs.

- Ensures that deicers are operating safely and efficiently before release for installation.

3. Maintenance and Repair

Maintains and repairs electric deicers in the field.

- Inspects deicers regularly for signs of wear or damage.

- Performs scheduled maintenance tasks, such as cleaning, lubrication, and component replacement.

- Troubleshoots and repairs any operational issues that arise.

4. Documentation and Record Keeping

Documents all assembly, inspection, testing, and repair activities.

- Maintains detailed records of work performed, materials used, and test results.

- Prepares and submits reports to management as required.

- Ensures that all documentation meets industry standards and regulatory requirements.

Interview Tips

1. Research the Company and Position

Take the time to learn about the company’s background, products or services, and industry standing. Also, thoroughly review the job description and identify the key responsibilities and qualifications.

- Visit the company’s website and social media pages.

- Read industry news and articles to understand the latest trends and best practices.

- Practice answering common interview questions related to the role and industry.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are most relevant to the job requirements. Quantify your accomplishments and provide specific examples to demonstrate your abilities.

- Focus on your hands-on experience in electric deicer assembly, testing, and maintenance.

- Provide examples of successful projects where you played a significant role.

- Highlight your knowledge of electrical systems, troubleshooting techniques, and industry regulations.

3. Demonstrate Enthusiasm and Passion

Show the interviewer that you are genuinely passionate about the role and the industry. Express your interest in the company’s mission and how your skills can contribute to their success.

- Share your motivations for pursuing a career as an Electric Deicer Assembler.

- Discuss your interest in electric deicing technology and its applications.

- Ask thoughtful questions about the company’s projects and future plans.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the opportunity. It also gives you a chance to gain additional insights into the company and the role.

- Prepare questions about the company’s growth strategy, innovation initiatives, or sustainability practices.

- Ask about the specific challenges and opportunities associated with the role.

- Inquire about the company’s commitment to training and development for employees.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Electric Deicer Assembler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Electric Deicer Assembler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.