Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electric Deicer Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

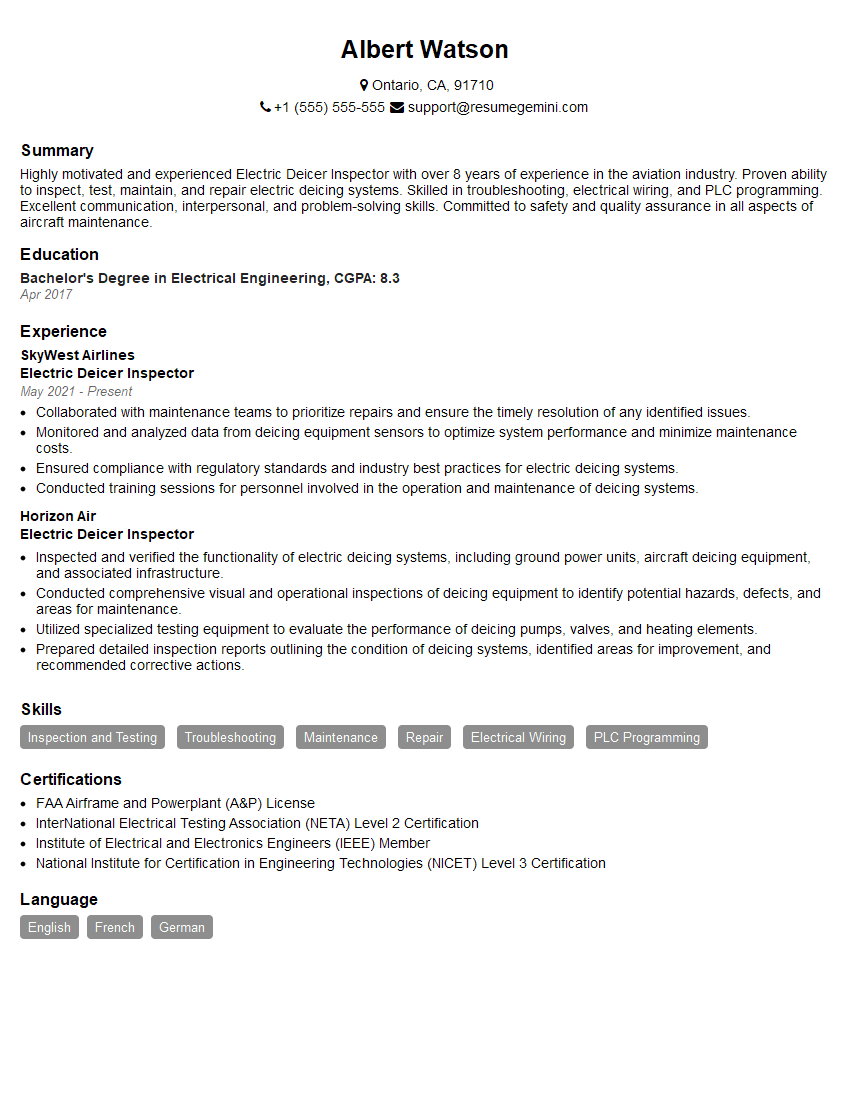

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Deicer Inspector

1. What are the key responsibilities of an Electric Deicer Inspector?

As an Electric Deicer Inspector, my key responsibilities include:

- Inspecting electric deicers to ensure they are installed, maintained, and operating properly

- Testing deicers to verify their functionality and performance

- Troubleshooting and diagnosing any issues or malfunctions with deicers

- Preparing and submitting inspection reports detailing findings and recommendations

- Maintaining up-to-date knowledge of industry standards and regulations

2. What are the different types of electric deicers and their principles of operation?

There are two main types of electric deicers:

- Heated deicers: These use electrical resistance heating elements to melt ice and snow.

- Fluid deicers: These circulate a heated fluid, such as glycol or ethylene glycol, through tubes or panels to prevent ice and snow buildup.

Both types of deicers operate on the principle of transferring heat to the surface to melt ice and snow.

Heated Deicers

- Use electrical resistance to generate heat

- Heat is transferred to the surface through a conductive element

- Commonly used for airport runways, taxiways, and aircraft surfaces

Fluid Deicers

- Circulate a heated fluid through tubes or panels

- Heat is transferred to the surface by conduction and convection

- Commonly used for bridges, overpasses, and sidewalks

3. What are the common electrical hazards associated with electric deicers and how can they be mitigated?

Common electrical hazards associated with electric deicers include:

- Ground faults

- Electrical shock

- Arc flash

- Overheating

These hazards can be mitigated by:

- Proper installation and grounding

- Regular inspection and maintenance

- Use of protective devices such as fuses and circuit breakers

- Training and education for personnel

4. What are the key performance metrics used to evaluate the effectiveness of electric deicers?

- Melting capacity (amount of ice and snow melted per unit time)

- Energy consumption

- Reliability (uptime and downtime)

- Maintenance costs

- Safety record

5. What are the different methods used to test the functionality of electric deicers?

- Visual inspection

- Electrical testing (continuity, insulation resistance, etc.)

- Performance testing (melting capacity, energy consumption)

- Functional testing (simulation of actual operating conditions)

6. What are the recommended maintenance procedures for electric deicers?

- Regular visual inspections for damage or wear

- Electrical testing to ensure proper operation

- Cleaning and debris removal

- Calibration and adjustment as needed

- Replacement of worn or damaged components

7. What are the industry standards and regulations governing the installation and operation of electric deicers?

- National Electrical Code (NEC)

- Occupational Safety and Health Administration (OSHA) regulations

- International Civil Aviation Organization (ICAO) standards

- Federal Aviation Administration (FAA) regulations (for airport applications)

8. Describe a situation where you successfully identified and resolved an issue with an electric deicer.

During a routine inspection, I noticed that one of the electric deicers on a bridge was not operating properly. I performed electrical testing and found that there was a loose connection in the control panel. I tightened the connection and the deicer started working again.

9. What are your strengths and weaknesses as an Electric Deicer Inspector?

Strengths:

- Strong technical knowledge of electric deicers

- Excellent troubleshooting and problem-solving skills

- Attention to detail and safety

- Effective communication and reporting skills

Weaknesses:

- Limited experience with large-scale airport deicing systems

- Currently pursuing certification in electrical engineering

10. Why are you interested in this position and how do you think your skills and experience align with our company’s needs?

I am eager to join your team because of your company’s reputation for excellence in the industry and your commitment to safety. My skills and experience in electric deicer inspection and maintenance align well with the requirements of this position. I am confident that I can make a significant contribution to your team and help ensure the safe and efficient operation of your electric deicing systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Deicer Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Deicer Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Deicer Inspectors play a critical role in ensuring the safety and reliability of aircraft operations. They are responsible for inspecting, testing, and maintaining electric deicing systems used to prevent ice accumulation on aircraft wings and control surfaces.

1. Inspection Duties

Inspect electric deicing systems according to established protocols and regulations.

- Visually examine components for damage, wear, and corrosion.

- Conduct electrical tests to verify system functionality.

2. Maintenance Responsibilities

Perform routine maintenance and repairs on electric deicing systems.

- Replace worn or faulty components.

- Clean and lubricate components as necessary.

3. Troubleshooting and Diagnostics

Troubleshoot and diagnose problems with electric deicing systems.

- Identify the root cause of system failures.

- Repair or replace damaged components.

4. Documentation and Reporting

Maintain detailed records of inspections, maintenance, and troubleshooting activities.

- Document system performance and identify any potential hazards.

- Report system failures and maintenance issues to supervisors and management.

Interview Tips

Preparing for an Electric Deicer Inspector interview requires a comprehensive understanding of the key job responsibilities and industry best practices. Here are some tips to help candidates ace their interviews:

1. Research the Company and Industry

Gather information about the company’s operations, safety record, and commitment to quality.

- Review the company’s website, social media presence, and industry publications.

- Research the regulatory environment and industry standards related to electric deicing systems.

2. Highlight Relevant Skills and Experience

Emphasize your experience in inspecting, maintaining, and troubleshooting electric deicing systems.

- Quantify your accomplishments and provide specific examples of your work.

- Discuss your knowledge of relevant codes and regulations.

3. Demonstrate Strong Technical Knowledge

Show your understanding of the principles of electricity, electronics, and aviation maintenance.

- Be prepared to discuss electrical theory, circuit analysis, and troubleshooting techniques.

- Explain your knowledge of aircraft maintenance procedures and safety protocols.

4. Prepare for Problem-Solving Questions

Interviewers may ask you to describe how you would approach troubleshooting a specific electric deicing system issue.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Provide clear and logical explanations of your thought process and decision-making.

5. Ask Thoughtful Questions

Asking insightful questions demonstrates your interest in the position and the company.

- Inquire about the company’s safety culture and training opportunities.

- Ask about the role’s responsibilities in the context of the overall aviation safety team.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Electric Deicer Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.