Are you gearing up for an interview for a Electric Fork Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Electric Fork Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

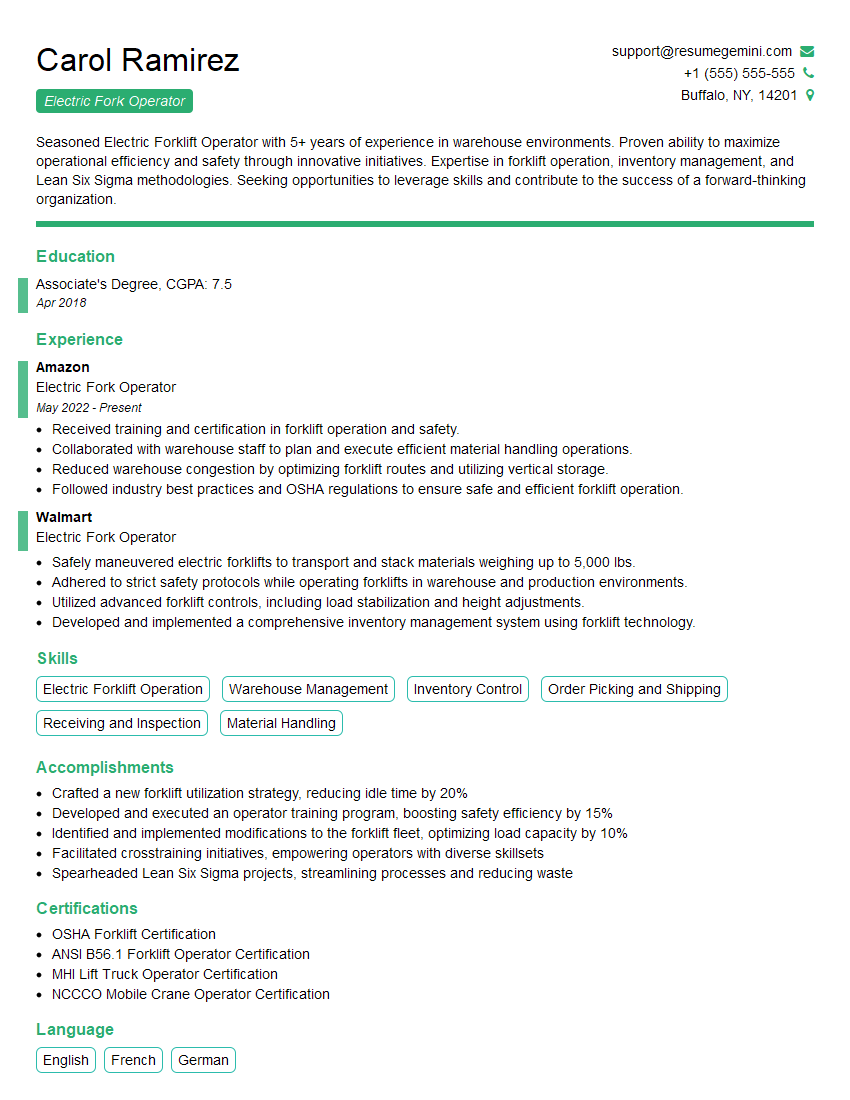

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Fork Operator

1. What are the daily responsibilities of an Electric Fork Operator?

As an Electric Fork Operator, my daily responsibilities would include:

- Operating electric forklifts to move materials, products, and equipment within a warehouse or production facility.

- Loading and unloading goods from trucks, trailers, and other vehicles.

- Stacking and unstacking materials in designated areas.

- Transporting materials and products to and from designated locations within the facility.

- Maintaining a clean and organized work area.

2. What are the safety precautions that must be taken when operating an electric forklift?

Pre-Operation Checks

- Inspect the forklift for any damage or defects before each use.

- Check the battery level and charge the forklift if necessary.

- Ensure that the forks are properly adjusted and secured.

During Operation

- Wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- Be aware of your surroundings and maintain a safe distance from other people and objects.

- Travel at a safe speed and avoid sudden starts and stops.

- Never lift loads that exceed the forklift’s capacity.

- Use caution when working on slopes or uneven surfaces.

3. What are the different types of electric forklifts and what are their advantages and disadvantages?

There are three main types of electric forklifts:

- Class I: Electric Rider Forklifts

- Advantages: Stable, comfortable, and suitable for indoor and outdoor use

- Disadvantages: Require more space to operate and have a higher initial cost

- Class II: Electric Stand-Up Forklifts

- Advantages: Smaller, more maneuverable, and ideal for confined spaces

- Disadvantages: Less stable and can be uncomfortable for extended use

- Class III: Electric Walkie Forklifts

- Advantages: Highly maneuverable, suitable for narrow aisles, and lower cost

- Disadvantages: Less powerful, requires more physical effort, and has a lower lift height

4. What are the basic principles of load handling and stability when operating an electric forklift?

- Load Center: The center of gravity of the load should be positioned directly over the forks.

- Lifting Capacity: Do not exceed the forklift’s rated lifting capacity.

- Stability Triangle: Ensure that the load is within the stability triangle formed by the forklift’s three wheels (or four wheels for a four-wheel forklift).

- Asymmetrical Loads: When handling asymmetrical loads, adjust the forks to compensate for the imbalance.

- Slopes and Uneven Surfaces: Approach slopes and uneven surfaces at a reduced speed and avoid sudden movements.

5. How do you maintain and troubleshoot common problems with electric forklifts?

- Regular Maintenance: Perform daily checks, including battery inspection, fluid levels, and visual inspection of the forklift.

- Battery Issues: Check battery connections, electrolyte levels, and charging system for any problems.

- Electrical Faults: Inspect wiring, fuses, and electrical components for any loose connections or damage.

- Hydraulic Problems: Check hydraulic fluid levels, hoses, and valves for any leaks or blockages.

- Braking System: Ensure that the brakes are functioning properly and replace worn brake pads or shoes.

6. What are the best practices for stacking and unstacking materials using an electric forklift?

- Stable Base: Ensure that the surface where you are stacking is level and stable.

- Proper Alignment: Align the forks properly with the load and insert them fully into the pallet.

- Load Distribution: Distribute the load evenly across the forks and ensure that it is secure.

- Lift Height: Lift the load to a safe height and avoid excessive stacking.

- Load Stability: Check the stability of the load before moving it and use a load backrest if necessary.

7. What are the potential hazards associated with operating an electric forklift and how can they be mitigated?

- Overturning: Avoid uneven surfaces, sharp turns, and excessive speed.

- Falling Objects: Ensure that loads are secure and avoid operating the forklift under suspended loads.

- Pedestrian Safety: Be aware of pedestrians and always yield the right of way.

- Electrical Hazards: Follow proper lockout/tagout procedures and avoid operating the forklift in wet or hazardous areas.

- Battery Safety: Charge the battery in well-ventilated areas and handle the battery with care.

8. What are the different types of attachments that can be used with an electric forklift and what are their applications?

- Fork Extensions: Extend the reach of the forks for handling long loads.

- Sideshifters: Allow the forks to move laterally for precise load placement.

- Rotators: Enable the load to be rotated for easy access.

- Clamps: Secure irregular or unstable loads.

- Drum Handlers: Handle heavy drums and barrels.

9. How do you prioritize safety when working in a fast-paced warehouse environment?

- Follow Safety Protocols: Adhere to all established safety guidelines and procedures.

- Situational Awareness: Be constantly aware of your surroundings and potential hazards.

- Defensive Driving: Operate the forklift defensively and anticipate the actions of others.

- Communication: Communicate clearly with other operators and pedestrians to avoid accidents.

- Continuous Improvement: Actively identify and address any potential safety risks.

10. Describe a situation where you had to troubleshoot and resolve a complex issue with an electric forklift.

Once, while working in a warehouse, the electric forklift I was operating suddenly lost power. I immediately pulled over to a safe location and began troubleshooting.

- First, I checked the battery connections and found them to be loose.

- I tightened the connections and tried restarting the forklift, but it still wouldn’t start.

- I then checked the electrical system and found a blown fuse. I replaced the fuse and the forklift started up again.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Fork Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Fork Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Fork Operators play a crucial role in warehouse and distribution operations. Their primary responsibility is to operate electric forklifts safely and efficiently to move heavy materials and products.

1. Material Handling

Electric Fork Operators are responsible for transporting, loading, and unloading materials using forklifts.

- Drive forklifts to move palletized materials within warehouses or distribution centers.

- Load and unload materials onto and off racks, trucks, and other vehicles.

2. Inventory Management

They assist in maintaining inventory records and ensuring the proper storage of materials.

- Monitor inventory levels and report any discrepancies to supervisors.

- Maintain accurate records of materials handled, including quantities and locations.

3. Equipment Maintenance

Electric Fork Operators are responsible for the upkeep and maintenance of their forklifts.

- Conduct daily inspections of forklifts and report any issues to maintenance personnel.

- Perform basic maintenance tasks, such as charging batteries and cleaning equipment.

4. Safety Compliance

It is essential that Electric Fork Operators prioritize safety in the workplace.

- Adhere to all safety protocols and regulations related to forklift operation.

- Wear appropriate personal protective equipment (PPE) while operating forklifts.

Interview Tips

To ace an interview for an Electric Fork Operator position, candidates should prepare thoroughly and showcase their skills and qualifications.

1. Research the Company and Position

Candidates should research the company’s industry, operations, and specific requirements for the Electric Fork Operator role.

- Visit the company’s website and social media pages to learn about their culture and values.

- Review the job description thoroughly and identify the key responsibilities and qualifications required.

2. Highlight Relevant Experience and Skills

In the interview, candidates should emphasize their relevant experience and skills that align with the job requirements.

- Quantify their accomplishments using specific metrics, such as the number of pallets moved or the percentage of inventory accuracy achieved.

- Describe their proficiency in operating different types of forklifts and any specialized certifications they hold.

3. Demonstrate Safety Awareness

Safety is paramount in this role, so candidates should highlight their commitment to safe forklift operation.

- Explain their understanding of forklift safety regulations and their experience in adhering to them.

- Describe any safety initiatives they have implemented or participated in.

4. Show Eagerness to Learn and Grow

Electric Fork Operators should demonstrate their willingness to learn and develop their skills.

- Express interest in receiving additional training or certifications related to forklift operation.

- Show enthusiasm for contributing to the team and taking on new challenges.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Fork Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!