Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electric Furnace Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

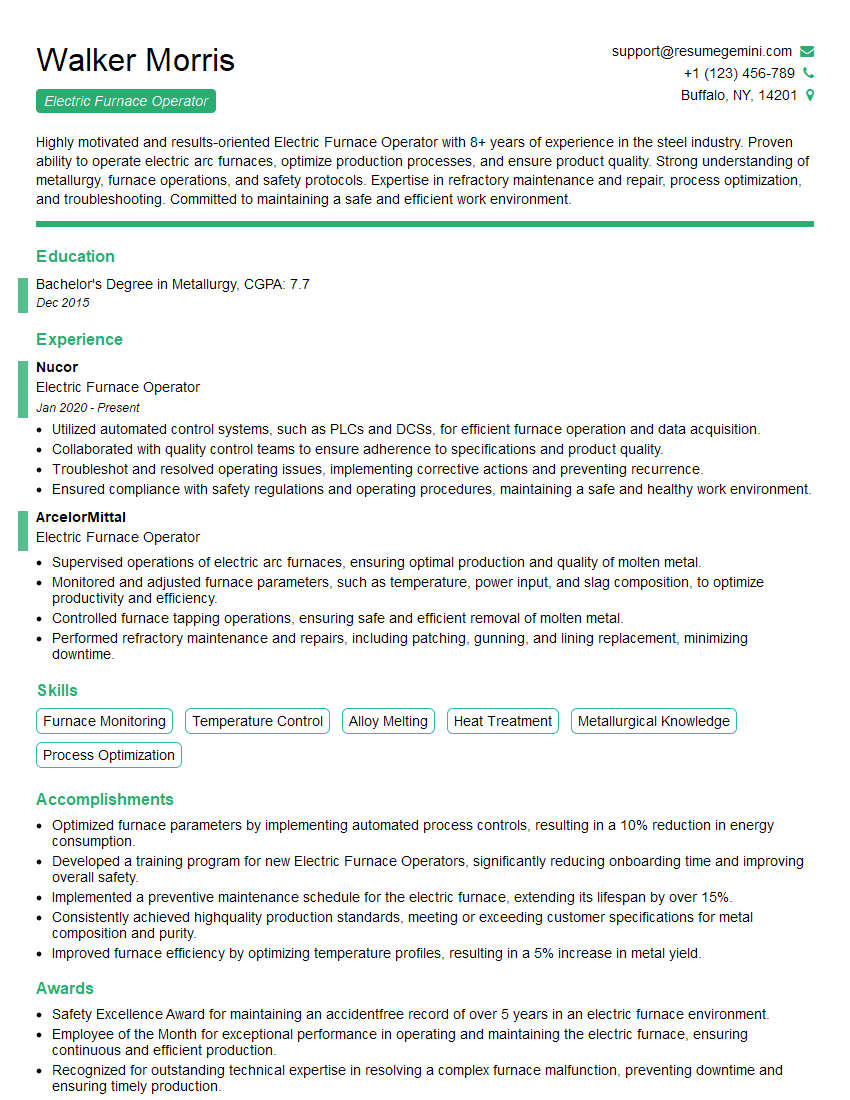

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Furnace Operator

1. Describe the steps involved in operating an electric furnace.

When operating an electric furnace, I follow these general steps:

- Inspect the furnace and ensure it’s in good working order.

- Load the raw materials into the furnace’s charging bucket.

- Operate the furnace controls to adjust temperature and atmosphere.

- Monitor the furnace’s performance and make adjustments as needed.

- Tap the furnace to release the molten metal.

- Clean and maintain the furnace after each use.

2. What safety precautions should be taken when working with an electric furnace?

General Safety

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a hard hat.

- Follow all safety procedures and protocols.

- Be aware of the potential hazards associated with electricity, heat, and molten metal.

- Never work alone near an electric furnace.

Electrical Safety

- Ensure proper grounding and electrical connections.

- Check for any exposed wires or damaged components.

- Lock out and tag out electrical systems before performing maintenance.

Heat and Molten Metal Safety

- Wear heat-resistant clothing and a face shield when working near the furnace.

- Keep a safe distance from molten metal and sparks.

- Use proper handling techniques and equipment when moving molten metal.

3. How do you determine the correct temperature for different types of metals?

Determining the correct temperature for different types of metals requires:

- Knowledge of the metal’s properties: Different metals have specific melting points and heat treatment requirements.

- Use of temperature measurement devices: Thermocouples or pyrometers are used to accurately measure the temperature inside the furnace.

- Consultation of technical specifications: Manufacturers provide recommended temperature ranges for various metal alloys.

- Experience and judgment: Experienced operators can often determine the optimal temperature based on the metal’s behavior and appearance.

4. Explain the process of charging and tapping an electric furnace.

Charging

- Prepare the charging bucket by lining it with refractory material and adding the desired raw materials.

- Position the charging bucket over the furnace and carefully pour the materials into the furnace chamber.

- Ensure proper distribution of the materials to avoid bridging or blockages.

Tapping

- When the metal has reached the desired composition and temperature, tilt the furnace to drain the molten metal into a ladle.

- Control the flow of molten metal using a stopper or slide gate mechanism.

- Transport the molten metal to the next processing stage, such as casting or rolling.

5. How do you maintain and troubleshoot an electric furnace?

Regular maintenance and troubleshooting are essential for ensuring the smooth operation of an electric furnace:

- Routine maintenance: Inspect furnace components, clean electrodes, replace refractories, and lubricate moving parts.

- Troubleshooting: Identify potential problems, such as electrode breakage, temperature fluctuations, or power outages, and take appropriate corrective actions.

- Collaboration with technicians: For complex issues, work with electrical, mechanical, or metallurgical technicians to resolve problems.

6. What are the different types of electric furnaces and their applications?

- Arc furnaces: Used for melting and refining scrap metal, producing steel and other alloys.

- Induction furnaces: Used for melting and heating metals in a crucible without direct contact with electrodes.

- Resistance furnaces: Used for heat treatment processes, such as annealing, hardening, and tempering.

- Vacuum furnaces: Used for melting and heat treating metals in a controlled atmosphere.

7. How do you optimize the efficiency of an electric furnace?

- Proper furnace design: Ensure the furnace is sized and designed to meet specific production requirements.

- Efficient charging and tapping practices: Minimize heat loss during charging and tapping operations.

- Optimized temperature control: Use temperature control systems to maintain the desired temperature with minimal energy consumption.

- Regular maintenance: Keep the furnace in good condition to prevent energy losses due to inefficiencies.

8. Describe the different types of electrodes used in electric furnaces and their advantages and disadvantages.

- Graphite electrodes: High electrical conductivity, low thermal expansion, but susceptible to oxidation.

- Carbon electrodes: Lower electrical conductivity, higher thermal expansion, but more resistant to oxidation.

- Composite electrodes: Combine the advantages of graphite and carbon electrodes, providing a balance of properties.

9. How do you handle slag and dross in an electric furnace?

- Slag formation: Slag forms as impurities in the metal react with fluxes to create a protective layer on the molten metal.

- Slag removal: During tapping, slag is removed by tilting the furnace and allowing it to flow out before the molten metal.

- Dross formation: Dross is formed when metal oxides accumulate on the surface of the molten metal.

- Dross removal: Dross is skimmed off the surface of the molten metal using a skimmer or rake.

10. What are the environmental considerations related to operating an electric furnace?

- Air pollution: Electric furnaces emit gases and dust, which can be controlled using pollution control devices.

- Water pollution: Wastewater from furnace operations must be treated to remove contaminants.

- Solid waste: Slag and dross from the furnace are considered hazardous waste and must be disposed of properly.

- Energy efficiency: Optimizing furnace operations reduces energy consumption and greenhouse gas emissions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Furnace Operators play a vital role in manipulating and managing electric arc furnaces to produce molten metal and alloys. Their key responsibilities include:

1. Furnace Operation

Supervise and control electric arc furnace operations, including charging, melting, refining, and tapping processes.

- Monitor furnace conditions, such as temperature, amperage, and voltage, to ensure optimal performance.

- Adjust furnace settings based on process specifications and metallurgical requirements.

2. Equipment Maintenance

Perform routine maintenance and inspections on furnaces, electrodes, and related equipment to ensure safe and efficient operation.

- Clean and lubricate equipment components, inspect for wear and tear, and make necessary repairs.

- Coordinate with maintenance personnel for major repairs or equipment overhauls.

3. Material Handling

Load and unload raw materials, such as scrap metal, fluxes, and alloys, into the furnace using cranes or forklifts.

- Monitor material flow and adjust charging rates to optimize production efficiency.

- Ensure proper storage and handling of materials to minimize waste and contamination.

4. Production Monitoring

Track production data, including furnace output, metal quality, and energy consumption, to identify areas for improvement.

- Work closely with laboratory technicians to analyze metal samples and maintain product quality.

- Maintain detailed operational records and report on furnace performance and production results.

Interview Tips

To ace the interview for an Electric Furnace Operator position, it’s crucial to highlight your technical expertise, problem-solving skills, and safety consciousness. Consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s products, processes, and the electric furnace industry. Research recent industry trends and innovations to show your interest and understanding of the field.

- Visit the company’s website, industry publications, and online forums to gather information.

- Identify the company’s key competitors and be prepared to discuss their strengths and weaknesses.

2. Highlight Your Technical Skills

Emphasize your proficiency in electric furnace operations, including charging, melting, refining, and tapping techniques. Quantify your experience with specific furnace models and types of metal alloys.

- Describe examples of how you optimized furnace performance and improved production efficiency.

- Discuss your understanding of electrical systems, instrumentation, and safety protocols related to electric furnaces.

3. Showcase Your Problem-Solving Abilities

Share examples of how you have effectively identified and resolved furnace operating issues. Explain your troubleshooting process, including data analysis, equipment inspection, and corrective actions taken.

- Describe situations where you had to adjust process parameters or implement new techniques to overcome challenges.

- Highlight your ability to work independently and make decisions in a fast-paced environment.

4. Emphasize Safety and Compliance

Electric furnace operation requires strict adherence to safety protocols. Emphasize your understanding of electrical hazards, confined space procedures, and proper handling of hazardous materials.

- Discuss your experience with safety audits, inspections, and training programs.

- Explain your commitment to maintaining a clean and organized work area to minimize risks.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Electric Furnace Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Electric Furnace Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.