Are you gearing up for an interview for a Electric Motor Assembler and Tester position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Electric Motor Assembler and Tester and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

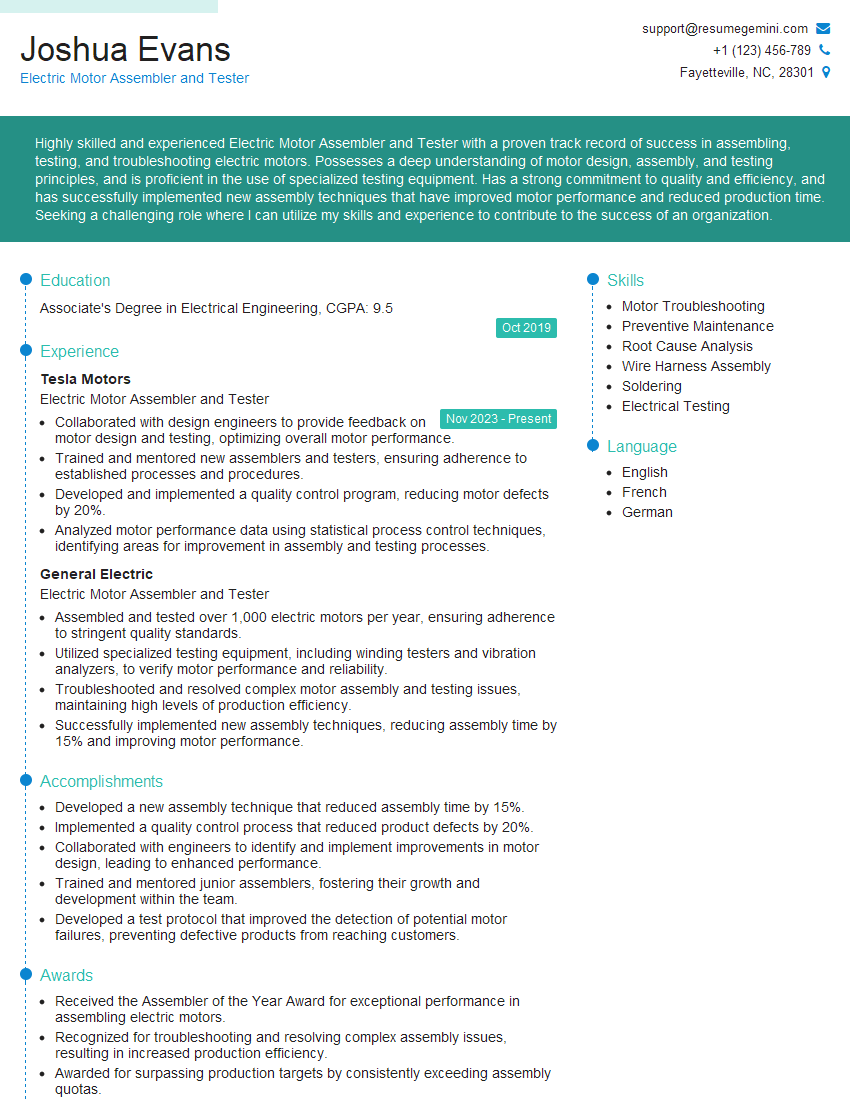

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Motor Assembler and Tester

1. Describe the key steps involved in assembling an electric motor.

The key steps involved in assembling an electric motor are as follows:

- Inspect and prepare the components, including the stator, rotor, bearings, and end caps.

- Assemble the stator by inserting the stator windings into the stator slots and connecting them to the terminal block.

- Insert the rotor into the stator and secure it using bearings and end caps.

- Connect the electrical leads to the motor terminals.

- Test the motor to ensure it is functioning properly.

2. What are the different types of electric motors and their applications?

AC Motors

- Induction motors: Used in industrial applications, appliances, and power tools due to their reliability, efficiency, and low maintenance.

- Synchronous motors: Used in applications requiring precise speed control, such as generators, clocks, and robotics.

DC Motors

- Brushed DC motors: Used in portable power tools, toys, and automotive starters due to their low cost and simplicity.

- Brushless DC motors: Used in high-performance applications, such as electric vehicles, drones, and industrial automation, due to their efficiency, durability, and low maintenance.

Other Types

- Stepper motors: Used in applications requiring precise positioning, such as CNC machines, printers, and medical devices.

- Servo motors: Used in applications requiring high torque and precise speed control, such as robotics, automation, and motion control systems.

3. How do you test the performance of an electric motor?

The performance of an electric motor can be tested using various methods, including:

- No-load test: Measures the motor’s speed, current, and voltage under no-load conditions.

- Load test: Measures the motor’s torque, speed, current, and voltage under different load conditions.

- Insulation resistance test: Measures the electrical resistance between the windings and the motor frame to ensure proper insulation.

- High-voltage test: Applies a high voltage to the motor to test its electrical integrity and identify any insulation weaknesses.

4. What are the common faults that can occur in electric motors and how do you troubleshoot them?

Common faults in electric motors include:

- Overheating: Caused by excessive current, poor ventilation, or bearing issues. Troubleshooting involves checking the motor’s load, ventilation, and bearings.

- Electrical faults: Including short circuits, open circuits, and insulation breakdown. Troubleshooting involves using a multimeter to check for continuity and insulation resistance.

- Mechanical faults: Such as bearing wear, misalignment, or vibration. Troubleshooting involves checking the bearings, alignment, and mounting.

- Noise and vibration: Can be caused by bearing issues, unbalanced rotors, or misalignment. Troubleshooting involves checking the bearings, balancing the rotor, and realigning the motor.

5. How do you ensure the quality and reliability of electric motor assemblies?

To ensure quality and reliability, I follow these practices:

- Adhere to established assembly procedures and specifications.

- Use calibrated tools and equipment for accurate measurements and assembly.

- Perform thorough visual and functional inspections at each assembly stage.

- Implement quality control checks and testing procedures to verify performance and identify any defects.

- Document all assembly and testing results for traceability and future reference.

6. What are the safety precautions that must be observed when working with electric motors?

To ensure safety when working with electric motors, I strictly adhere to the following precautions:

- Always de-energize the motor before performing any maintenance or repairs.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and insulating footwear.

- Use insulated tools and equipment designed for electrical work.

- Follow lockout/tagout procedures to prevent accidental energization.

- Be aware of the potential for electrical hazards, such as arc flash and shock.

7. How do you stay up-to-date with the latest developments and technologies in electric motor assembly and testing?

To stay current with advancements in the field, I:

- Attend industry conferences and workshops.

- Read technical publications and research papers.

- Participate in online forums and discussion groups.

- Collaborate with experts in the field through networking and mentorship.

- Take advantage of training opportunities provided by manufacturers and professional organizations.

8. Describe your experience in troubleshooting and repairing electric motors.

Throughout my career, I have encountered and resolved various electric motor issues. These experiences include:

- Identifying and repairing electrical faults, such as short circuits and open circuits, using multimeters and other diagnostic tools.

- Diagnosing and replacing faulty bearings, which cause excessive noise and vibration.

- Troubleshooting misaligned motors, which can lead to premature wear and tear.

- Repairing damaged windings and commutators to restore motor functionality.

- Conducting performance tests to ensure motors meet specifications and operate reliably.

9. How do you handle working in a fast-paced and demanding manufacturing environment?

In fast-paced manufacturing environments, I thrive by:

- Prioritizing tasks and managing my time effectively to meet deadlines.

- Maintaining a high level of accuracy and attention to detail in all aspects of my work.

- Working collaboratively with team members to achieve common goals.

- Adapting quickly to changes in production schedules and requirements.

- Maintaining a positive and proactive attitude, even under pressure.

10. Why are you interested in this Electric Motor Assembler and Tester position?

I am highly interested in this Electric Motor Assembler and Tester position for several reasons:

- My skills and experience in electric motor assembly and testing align perfectly with the requirements of the role.

- I am eager to contribute my knowledge and expertise to your team.

- I am passionate about the electric motor industry and believe that I can make a valuable contribution to your organization.

- I am confident that I can quickly become a productive member of your team and help you achieve your business goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Motor Assembler and Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Motor Assembler and Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Electric Motor Assembler and Tester combines mechanical and electrical skills to assemble and test electric motors. This intricate role includes the fundamental responsibilities of:

1. Assembly of Electric Motors

To successfully assemble electric motors, candidates must:

- Follow blueprints and assembly instructions meticulously to ensure accurate construction.

- Select and secure the appropriate components for assembly, including stators, rotors, shafts, bearings, and housings.

- Utilize hand tools, power tools, and specialized equipment to assemble the motor components securely and efficiently.

- Tighten bolts, nuts, and screws to specified torque values, ensuring proper alignment and performance.

2. Testing and Calibration of Electric Motors

To ensure the proper functionality of the assembled motors, candidates are required to:

- Connect motors to appropriate power sources and run them under various load conditions.

- Utilize testing equipment, such as multimeters, tachometers, and oscilloscopes, to measure and evaluate electrical parameters.

- Analyze test results and make adjustments to the motor’s assembly or components as needed to meet performance specifications.

- Document test results and record any deviations or non-conformities.

3. Troubleshooting and Repair

To address issues that may arise during assembly or testing, candidates must possess the ability to:

- Identify and diagnose potential problems with electric motors, using their knowledge of electrical and mechanical principles.

- Disassemble motors to locate and replace faulty components, such as windings, brushes, or bearings.

- Troubleshoot electrical issues, including shorts, open circuits, and voltage fluctuations.

- Make necessary repairs to restore the motors to proper operating condition.

4. Quality Assurance

To ensure the motors meet customer requirements, candidates are responsible for:

- Inspecting motors for defects or non-conformities.

- Performing final tests and inspections to verify that motors meet performance specifications.

- Adhering to quality control procedures and maintaining accurate documentation.

- Providing feedback to improve assembly and testing processes.

Interview Tips

Succeeding in an interview for the role of Electric Motor Assembler and Tester requires proper preparation. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Gain insights into the company’s mission, values, and products or services. Familiarize yourself with the industry trends and key players to demonstrate your knowledge and interest.

- Example: Highlight your understanding of the company’s focus on sustainability and their recent expansion into the electric vehicle market.

2. Practice Your Technical Skills

Be ready to discuss your technical abilities in detail. Review your electrical and mechanical knowledge, including concepts related to motors, circuits, and testing procedures.

- Example: Explain your proficiency in using oscilloscopes and multimeters for motor testing.

3. Showcase Your Problem-Solving Abilities

Emphasize your ability to troubleshoot and repair motors. Provide examples of how you have identified and resolved issues in previous roles.

- Example: Describe a situation where you successfully diagnosed and repaired an issue with a motor’s winding.

4. Highlight Your Quality Control Experience

Stress your commitment to quality by discussing your experience in adhering to quality control procedures and ensuring that motors meet specifications.

- Example: Explain your role in implementing a new quality control process that reduced defects by 20%.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Motor Assembler and Tester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.